Minimum cossie head thickness????

#81

just finding my feet

With YB's people worry too much

with a N?A runabout ya run it on the cheepest fuel ya can buy, check the oil when the little oil check light comes on when taking corners

with a cossie if theres a funny smell out side in the country ya pull over and call the AA out to be told its the farm over yonder

#82

PassionFord Post Whore!!

Join Date: May 2003

Location: SE

Posts: 9,226

Likes: 0

Received 0 Likes

on

0 Posts

So If the height of head is below 138.68mm on std pistons, will there be any valve piston contact?.. or is it simply the valve seat area which becomes the issue?

#83

Too many posts.. I need a life!!

Join Date: May 2004

Location: in the garage fixing yet another oil leak

Posts: 925

Likes: 0

Received 0 Likes

on

0 Posts

stu / karl

early cosworth group a 2wd pistons pa1079/6.2cr i think, had only very small squish assisting raised area on top. also they stopped about a mile short of the block face. whats going on here then, does a lower static cr mean less squish required?

excellent tread BTW

early cosworth group a 2wd pistons pa1079/6.2cr i think, had only very small squish assisting raised area on top. also they stopped about a mile short of the block face. whats going on here then, does a lower static cr mean less squish required?

excellent tread BTW

#84

I've found that life I needed.. It's HERE!!

Originally Posted by frog

Here's how I understand it...

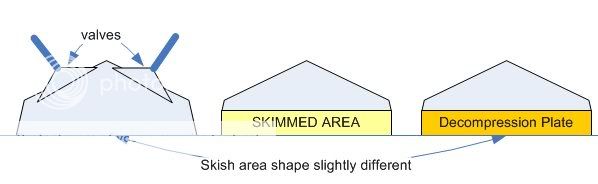

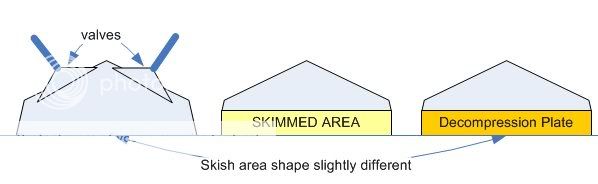

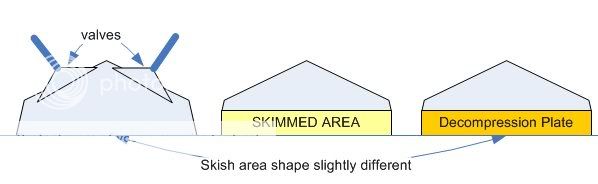

In the picture above, the decomp. plate only replaces the same amount of material that was removed by the skim(s).

However, because the walls of the plate are vertical, the squish area has changed shape.

Over to you Stu...

In the picture above, the decomp. plate only replaces the same amount of material that was removed by the skim(s).

However, because the walls of the plate are vertical, the squish area has changed shape.

Over to you Stu...

The red blobs on the leftmost diagram show the squish area, as the piston travels up the bore, the mixture is guided towards the centre of the combustion area. Now if you skim the head alot (middle diagram) or remove the squish area, there is alot less (sometimes nothing) squish area to guide the mixture to the centre of the combustion area. Adding a decompressin plate does nothing to aid this, as it is just an extension of the bore, it makes more space between the top of the piston and the cylinder head, but doesn't put back your squish area

#85

Originally Posted by frog

When you add the plate in picture 3, you actually RAISE the head by an amount.

Does that help?

Maybe if you see where the squish area is on a YB cylinder head?

#88

0-60 in 17 seconds (eek)

Join Date: Apr 2004

Location: Berkshire

Posts: 6,717

Likes: 0

Received 0 Likes

on

0 Posts

wes, I agree 100% with you, your drawing is indeed more accurate and representative.

Now, if the decomp. plate reproduced the slope (As it was suggested above), would that be ok ?

As for worrying... I worry that if my engine blows up I will have to spend ££££'s putting it back together, so I'd rather make sure it's as good as I can get it whenever it's in pieces.

If that means a new head, rather than taking chances with 16 valves or holes in pistons, a new head is the cheaper long term alternative - it's not worrying, it's financial planning...

I am actually in the process of putting my other half's car back together, and have two heads that are both below min. thickness... (hence my keen interest in this post ). Now do I take a chance with either and cross fingers, or, do I fix it properly now ???

). Now do I take a chance with either and cross fingers, or, do I fix it properly now ???

Now, if the decomp. plate reproduced the slope (As it was suggested above), would that be ok ?

As for worrying... I worry that if my engine blows up I will have to spend ££££'s putting it back together, so I'd rather make sure it's as good as I can get it whenever it's in pieces.

If that means a new head, rather than taking chances with 16 valves or holes in pistons, a new head is the cheaper long term alternative - it's not worrying, it's financial planning...

I am actually in the process of putting my other half's car back together, and have two heads that are both below min. thickness... (hence my keen interest in this post

#89

0-60 in 17 seconds (eek)

Join Date: Apr 2004

Location: Berkshire

Posts: 6,717

Likes: 0

Received 0 Likes

on

0 Posts

We did all come back to this together didn't we ? Had enough of the muppet room for the evening ?

100% with you here.

what if you raise it by the X amount you took off above ? That's what I don't really get.

Only thing that's clear in my mind is that the physical shape of the bit you take off when you skim is not the same as that of the decomp. plate.

Originally Posted by Stu @ M Developments

in reality all you will have done is dropped the whole head down "X"amount.

Originally Posted by Stu @ M Developments

When you add the plate in picture 3, you actually RAISE the head by an amount.

Only thing that's clear in my mind is that the physical shape of the bit you take off when you skim is not the same as that of the decomp. plate.

#90

Too many posts.. I need a life!!

Originally Posted by Karl

PJ,

The method I use involves stress relieving the head during the welding process as well as having the head pre heated(I don't want to say what I do as thats giving the game away) but it results in a very hard head face and is totally reliable.

The method I use involves stress relieving the head during the welding process as well as having the head pre heated(I don't want to say what I do as thats giving the game away) but it results in a very hard head face and is totally reliable.

I weld the cylinder bores on 2 stroke cylinders prior to the surface being Re plated ( Ceramic coating) and know only to well how this affects the strength of the substrate alloy.

#91

I've found that life I needed.. It's HERE!!

Originally Posted by Stu @ M Developments

Jees, we all came back at once

but also

but also

Originally Posted by frog

Now, if the decomp. plate reproduced the slope (As it was suggested above), would that be ok ?

As for worrying... I worry that if my engine blows up I will have to spend ££££'s putting it back together, so I'd rather make sure it's as good as I can get it whenever it's in pieces.

If that means a new head, rather than taking chances with 16 valves or holes in pistons, a new head is the cheaper long term alternative - it's not worrying, it's financial planning...

I am actually in the process of putting my other half's car back together, and have two heads that are both below min. thickness... (hence my keen interest in this post ). Now do I take a chance with either and cross fingers, or, do I fix it properly now ???

). Now do I take a chance with either and cross fingers, or, do I fix it properly now ???

As for worrying... I worry that if my engine blows up I will have to spend ££££'s putting it back together, so I'd rather make sure it's as good as I can get it whenever it's in pieces.

If that means a new head, rather than taking chances with 16 valves or holes in pistons, a new head is the cheaper long term alternative - it's not worrying, it's financial planning...

I am actually in the process of putting my other half's car back together, and have two heads that are both below min. thickness... (hence my keen interest in this post

If the head has been extensivley worked on then i'd ask Karl about the welding and maching to get it back to original thickness, if it's a bog standard head (apart from the skimming) then again either talk to Karl or source 2nd hand ones, and keep the skimmed ones for a rainy day (when all the good yb heads run out

)

)

#96

BRILLIANT thread!

Stu - you say that you get a better burn if the fuel goes to the centre of the piston therefore create a bowl in the piston rather then skimming the tops of the pistons so would it be worth doing this to a mahle in a cvh engine rather then skimming them flat!?

Karl - can you also weld onto a cvh head too? also are we still on for saturday please say yes

please say yes

Stu - you say that you get a better burn if the fuel goes to the centre of the piston therefore create a bowl in the piston rather then skimming the tops of the pistons so would it be worth doing this to a mahle in a cvh engine rather then skimming them flat!?

Karl - can you also weld onto a cvh head too? also are we still on for saturday

#98

10K+ Poster!!

iTrader: (2)

i have reclaimed head by various methods , but would be seriously sceptical about having the face completely welded and re machined simply because of hardness issues  thats not to say it cannot be done , karl, you must have done this succesfully otherwise you wouldnt mention it , just one of those things i wouldnt have done till id tested it myself

thats not to say it cannot be done , karl, you must have done this succesfully otherwise you wouldnt mention it , just one of those things i wouldnt have done till id tested it myself

though i must admit ive rewelded stuff and machined it back to good as new that alot of people said was scrap

thats not to say it cannot be done , karl, you must have done this succesfully otherwise you wouldnt mention it , just one of those things i wouldnt have done till id tested it myself

thats not to say it cannot be done , karl, you must have done this succesfully otherwise you wouldnt mention it , just one of those things i wouldnt have done till id tested it myself though i must admit ive rewelded stuff and machined it back to good as new that alot of people said was scrap

#99

0-60 in 17 seconds (eek)

Join Date: Apr 2004

Location: Berkshire

Posts: 6,717

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by markk

i have reclaimed head by various methods

#100

10K+ Poster!!

iTrader: (9)

Join Date: May 2004

Location: birmingham west mids

Posts: 11,919

Likes: 0

Received 11 Likes

on

9 Posts

1) rarther than a decomp plate, would one of those copper head gaskets (is it ferriday make them?  ) be a viable alternative, as there is no gasket as such, and the squish area could be built back in by shaping the gasket?

) be a viable alternative, as there is no gasket as such, and the squish area could be built back in by shaping the gasket?

2) does the squish area on a 2wd and 4x4 head vary? I know they are diff in combustion chamber design, ie pent roof and rounded.

3) do valve cutouts in pistons promote hotspots and det?

awsome topic, keep the tech info coming best read i've had 4 ages

best read i've had 4 ages

2) does the squish area on a 2wd and 4x4 head vary? I know they are diff in combustion chamber design, ie pent roof and rounded.

3) do valve cutouts in pistons promote hotspots and det?

awsome topic, keep the tech info coming

#101

0-60 in 17 seconds (eek)

Join Date: Apr 2004

Location: Berkshire

Posts: 6,717

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by RWD_cossie_wil

1) rarther than a decomp plate, would one of those copper head gaskets (is it ferriday make them?  ) be a viable alternative, as there is no gasket as such, and the squish area could be built back in by shaping the gasket?

) be a viable alternative, as there is no gasket as such, and the squish area could be built back in by shaping the gasket?

-Copper headgasket, only up to a certain thickness.

-Decompression plate, thicker than H/G, but then you need a "normal" i.e. non-copper head gasket to go with.

Their copper headgasket has fire rings (or something else) machined in it, so they can't make it too thick.

#103

PassionFord Post Whore!!

Join Date: May 2003

Location: Wiltshire UK

Posts: 3,795

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Stu @ M Developments

I think people are still not following what part of the head makes up the squish here, but i cant think of a good way to put it into words....

I thought my dodgy sketch may make it clearer..

if you have a spacer plate with a 90-odd millimetre circular bore (ie to the gasket line on the picture), the shaded areas of the head (the squish area) will be spaced apart from the block face (and obviously the piston crown)

#104

PassionFord Post Whore!!

I'm understanding that Rich

So, if the plate is made to include the bits you have shaded, rather than just round holes, does that make it OK?

(back to what I originally asked

)

)

So, if the plate is made to include the bits you have shaded, rather than just round holes, does that make it OK?

(back to what I originally asked

)

)

#105

PassionFord Post Whore!!

Join Date: May 2003

Location: Wiltshire UK

Posts: 3,795

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by St3V3_C

I'm understanding that Rich

So, if the plate is made to include the bits you have shaded, rather than just round holes, does that make it OK?

(back to what I originally asked

)

)

So, if the plate is made to include the bits you have shaded, rather than just round holes, does that make it OK?

(back to what I originally asked

)

)yeah, in theory, but the unsupported area would just not be stable enough IMO.. and we are then missing the point - the primary problem isn't a 'dangerous' compression issue (makes around 0.2 CR increase at minimum thickness or thereabouts) but rather the issue of breaking into the valve seat inserts.. so the plate would not help that at all..

#106

Here's a question...........

If the head has been skimmed to it's limit, does this mean that where the squish area was dome shaped, but now has a flat step at the valve seat edge, that yo're gonna be more prone to hot spots in that area?

If the head has been skimmed to it's limit, does this mean that where the squish area was dome shaped, but now has a flat step at the valve seat edge, that yo're gonna be more prone to hot spots in that area?

#107

PassionFord Post Whore!!

Join Date: May 2003

Location: Wiltshire UK

Posts: 3,795

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by RichardPON

Here's a question...........

If the head has been skimmed to it's limit, does this mean that where the squish area was dome shaped, but now has a flat step at the valve seat edge, that yo're gonna be more prone to hot spots in that area?

If the head has been skimmed to it's limit, does this mean that where the squish area was dome shaped, but now has a flat step at the valve seat edge, that yo're gonna be more prone to hot spots in that area?

How do you mean 'dome shaped'?

The squish area on the head is flat in both cases, the skim makes very little difference to the squish area, it gets marginally wider towards the valve seats as you machine into the sloped chamber wall, but very little changes..

138.8mm:

139.2mm:

you can see the flat squish area above the inlet valves in these pictures is almost identical..

#108

PassionFord Post Troll

Join Date: Sep 2004

Location: Next to my frog...

Posts: 2,795

Likes: 0

Received 0 Likes

on

0 Posts

I think I followed all that and finally managed to understand the squish thingy..

Have made a drawing in power point... so asking the man to covert it into a .jpeg or .gif to post it...

Have made a drawing in power point... so asking the man to covert it into a .jpeg or .gif to post it...

#109

PassionFord Post Troll

Join Date: Sep 2004

Location: Next to my frog...

Posts: 2,795

Likes: 0

Received 0 Likes

on

0 Posts

I know its quite a bad drawing but the way I see it is the first drawing is a "normal" head, never been skimmed, with red area being the squish area.

Second drawing, head been skimmed and the white bit is the part of the squish that has been "lost" in the skim. Am I right there?

Third is with a decomp. plate added (red). As the plate is around the valve area only and does not replace the squish that is missing(white area), the head has just been raised... still ok?

Fourth is I guess the sort of plate that would be needed to get the squish back to normal....

Am I almost right or shall I get back to my kitchen???

#110

I've found that life I needed.. It's HERE!!

Yes you've got it pretty much right, however the decomp plate shaped to the squish area will require 2 headgaskets, so there will also be a space between the plate and the head, which would lead to even futher problems!

#111

PassionFord Post Whore!!

Join Date: May 2003

Location: Wiltshire UK

Posts: 3,795

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by wes

Yes you've got it pretty much right, however the decomp plate shaped to the squish area will require 2 headgaskets, so there will also be a space between the plate and the head, which would lead to even futher problems!

#113

PassionFord Post Troll

Join Date: Sep 2004

Location: Next to my frog...

Posts: 2,795

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by wes

Yes you've got it pretty much right, however the decomp plate shaped to the squish area will require 2 headgaskets, so there will also be a space between the plate and the head, which would lead to even futher problems!

As Greg (my other half) said before, we're in need of a working head. So really, what's the best thing to do? Get a new head now while they are still available or try to have ours reconditioned?....

Because from what I understand, there is no way once the head has been skimmed to actually get it back to absolute "normal" like it was when new, whichever solution is chosen. I guess that would alsomean the car would need to be remapped then to compensate for the "loss of squish"...

How would that affect the performance and reliability (or lack of...

) of the car?

) of the car?

#114

PassionFord Post Whore!!

Join Date: May 2003

Location: Wiltshire UK

Posts: 3,795

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by wes

Which other method of sealing could you use that would not leave a gap between the plate squish sections and the head?

essentially the same as we used here (although we did the other way up, plate to block and gasket between plate and head):

http://www.rsrich.force9.co.uk/zetec...090014_jpg.htm

http://www.rsrich.force9.co.uk/zetec...090015_JPG.htm

#115

I've found that life I needed.. It's HERE!!

If you can get hold of a brand new head then that is the best starting point, when i had my engine built i bought a new one, it was then machined to grp A spec, i didn't want to spend the money on the work to be done and then find the head would be scrap if it needed one skim at any point in the future. Next best option is to source a 2nd hand head that hasn't been skimmed ever.

You really should speak to Karl 1st though about the welding and refinishing, as a new head is about £1000 - £1500 + VAT!

You really should speak to Karl 1st though about the welding and refinishing, as a new head is about £1000 - £1500 + VAT!

#116

0-60 in 17 seconds (eek)

Join Date: Apr 2004

Location: Berkshire

Posts: 6,717

Likes: 0

Received 0 Likes

on

0 Posts

Has anyone seen the little insert on page 10 of Performance Ford this month (april 2005) ?

There's something in there about Ferriday engineering being able to CNC machine the head's combustion chamber for a head that's been skimmed.

Can someone who knows what they are talking about check this for me please, better still, give them a call (mike 01785 621 710) and find out what the deal is ?

There's no point me calling him, whatever he'll tell me will sound like gospel cos I haven't got a clue

CheeRS guys.

There's something in there about Ferriday engineering being able to CNC machine the head's combustion chamber for a head that's been skimmed.

Can someone who knows what they are talking about check this for me please, better still, give them a call (mike 01785 621 710) and find out what the deal is ?

There's no point me calling him, whatever he'll tell me will sound like gospel cos I haven't got a clue

CheeRS guys.

#118

PassionFord Post Whore!!

Join Date: May 2003

Location: Wiltshire UK

Posts: 3,795

Likes: 0

Received 0 Likes

on

0 Posts

just as a reminder... may be useful to get back to an early stage of the discussion that we've maybe strayed from..

-------------------------------------------

Quote from Stu:

Brad,

Its a misconception that the head becomes "Too thin, or weak" and also that its about the altered "Compression Ratio"

The issue is the area around the valve seat becomes dangerously thin after 138.68mm.

-------------------------------------------

the compression change isn't so much the issue as the machined face breaking into the valve seats... (compression increases to about 8.2:1 for a 0.5mm material loss).

spacer plates and chamber machining won't change this at all..

-------------------------------------------

Quote from Stu:

Brad,

Its a misconception that the head becomes "Too thin, or weak" and also that its about the altered "Compression Ratio"

The issue is the area around the valve seat becomes dangerously thin after 138.68mm.

-------------------------------------------

the compression change isn't so much the issue as the machined face breaking into the valve seats... (compression increases to about 8.2:1 for a 0.5mm material loss).

spacer plates and chamber machining won't change this at all..

#119

0-60 in 17 seconds (eek)

Join Date: Apr 2004

Location: Berkshire

Posts: 6,717

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by richm

just as a reminder... may be useful to get back to an early stage of the discussion that we've maybe strayed from..

Originally Posted by richm

-------------------------------------------

Quote from Stu:

Brad,

Its a misconception that the head becomes "Too thin, or weak" and also that its about the altered "Compression Ratio"

The issue is the area around the valve seat becomes dangerously thin after 138.68mm.

-------------------------------------------

the compression change isn't so much the issue as the machined face breaking into the valve seats... (compression increases to about 8.2:1 for a 0.5mm material loss).

Quote from Stu:

Brad,

Its a misconception that the head becomes "Too thin, or weak" and also that its about the altered "Compression Ratio"

The issue is the area around the valve seat becomes dangerously thin after 138.68mm.

-------------------------------------------

the compression change isn't so much the issue as the machined face breaking into the valve seats... (compression increases to about 8.2:1 for a 0.5mm material loss).

Would live mapping be required to counteract the increase in compression ratio ?

#120

PassionFord Post Whore!!

Join Date: May 2003

Location: Wiltshire UK

Posts: 3,795

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by frog

Rich, I agree the discussion is very interesting from a technical point of view, but I think a few valid points were made regarding resurrecting otherwise scrap heads. This is probably of significant interest to quite a few people since decent quality heads are rarer than hen's teeth.

although IMO Karls welding reclamation is the only one relevant due to the seat exposure issues, which any form of decompression plate or chamber machining will not address.

although IMO Karls welding reclamation is the only one relevant due to the seat exposure issues, which any form of decompression plate or chamber machining will not address.

for the morning crew.

for the morning crew.