Minimum cossie head thickness????

#41

frog,

So from the above, a dished piston is better than one that has four little pockets (from a combustion point of view), cos the one with the four pockets would appear "domed" rather than "bowled" ?

So from the above, a dished piston is better than one that has four little pockets (from a combustion point of view), cos the one with the four pockets would appear "domed" rather than "bowled" ?

The pockets are a necessity for valve head clearance during maximum lift with some cams such as BD15s etc.

What i am saying, is that if you require a removal of say, 5cc from the piston crown to get the CR you want, instead of literally skimming 30thou of the tops of the pistons, you should have a machine shop machine the tops everywhere so as to retain the original bowl shape and as much of the original height as possible, and thus maintain your original squish clearance. That help?

And yes, one day we will run out of heads

#44

0-60 in 17 seconds (eek)

Join Date: Apr 2004

Location: Berkshire

Posts: 6,717

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by brad

frog if your running wild cams you would need valve pockets tho wouldnt you

oops too slow

oops too slow

but doesn't that tend to make the piston look more domed overall ? Thus creating the pockets stu was on about ?

but doesn't that tend to make the piston look more domed overall ? Thus creating the pockets stu was on about ?

#47

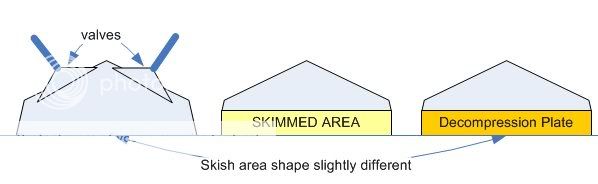

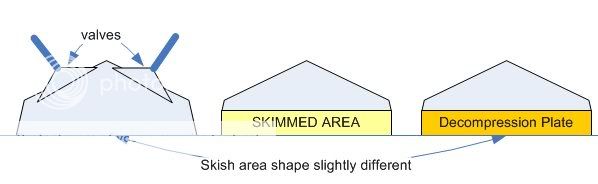

You can see the piston shape here if it helps you to imagine how the outer edge is raised to effectively "Funnel" the mixture to teh middle as it reaches TDC.

If your pistons end up down the bore when sat at TDC, the tops have had a lot removed from them. A Std squish has teh piston 20thou above deck height.

*

Edited to say, thats a crap picture actually, too much glare

If your pistons end up down the bore when sat at TDC, the tops have had a lot removed from them. A Std squish has teh piston 20thou above deck height.

*

Edited to say, thats a crap picture actually, too much glare

#48

0-60 in 17 seconds (eek)

Join Date: Apr 2004

Location: Berkshire

Posts: 6,717

Likes: 0

Received 0 Likes

on

0 Posts

It's pretty clear on that picture stu, but the pockets look quite small. I am sure I have seen pistons with pockets so deep they almost looked like the piston had a domed overall shape.

Anyway that's not really important - I am not too sure why I am labouring the point

Anyway that's not really important - I am not too sure why I am labouring the point

#49

PassionFord Post Troll

Join Date: Apr 2004

Location: West Sussex

Posts: 3,174

Likes: 0

Received 0 Likes

on

0 Posts

so basicly , the edges of the piston ideally should be kept as close to standard height as poss and the bowl machined down as evenly as poss across the width of the original bowl  or am i gettin confuddled ?

or am i gettin confuddled ?

#53

Originally Posted by brad

so basicly , the edges of the piston ideally should be kept as close to standard height as poss and the bowl machined down as evenly as poss across the width of the original bowl  or am i gettin confuddled ?

or am i gettin confuddled ?

#54

0-60 in 17 seconds (eek)

Join Date: Apr 2004

Location: Berkshire

Posts: 6,717

Likes: 0

Received 0 Likes

on

0 Posts

Stu, just thinking about it all again, I am not sure we talk about the same thing when we talk about decompression plates...

If I understand correctly, when the head is skimmed, it looses a given amount of metal, and the overall depth of the "combustion area" in the head reduces. A decompression plate as I understand it, would recover this depth loss.

Is that what you were on about too ? Cos I can understand how it affects the squish area, but it only brings it back to where it was before the skim

If I understand correctly, when the head is skimmed, it looses a given amount of metal, and the overall depth of the "combustion area" in the head reduces. A decompression plate as I understand it, would recover this depth loss.

Is that what you were on about too ? Cos I can understand how it affects the squish area, but it only brings it back to where it was before the skim

#55

PassionFord Post Troll

Join Date: Apr 2004

Location: West Sussex

Posts: 3,174

Likes: 0

Received 0 Likes

on

0 Posts

so the chamferd (sp?) edge on the piston bowl keeps the explosion away from the block/head walls and directly underneath the valves in an evenly spaced area helping to avoid hotspots in the squeeze area .

#56

Norris Motorsport

Before everyone discards their over skimmed heads, I can fully weld the entire head face and remachine the entire face, water ways and chambers to restore the head to as new!!!! It is'nt cheap but it does give new life to an otherwise scrap head!

I can of course recess valves and tip the valve stems for those heads that are around the 138.5mm area, but anything much below that needs the above welding work!

I can of course recess valves and tip the valve stems for those heads that are around the 138.5mm area, but anything much below that needs the above welding work!

#58

Too many posts.. I need a life!!

Originally Posted by Karl

Before everyone discards their over skimmed heads, I can fully weld the entire head face and remachine the entire face, water ways and chambers to restore the head to as new!!!! It is'nt cheap but it does give new life to an otherwise scrap head!

I can of course recess valves and tip the valve stems for those heads that are around the 138.5mm area, but anything much below that needs the above welding work!

I can of course recess valves and tip the valve stems for those heads that are around the 138.5mm area, but anything much below that needs the above welding work!

#59

10K+ Poster!!

iTrader: (5)

dont want t sound thick but im interested in how you measeure the head

i mean where would you measure the depth from

would it be from the back of the head from centre of the top to the mating surface of the bottom

obviously digital vernier to do this

as im getting worried now that my head may be scrap and getting the engine built soon

i mean where would you measure the depth from

would it be from the back of the head from centre of the top to the mating surface of the bottom

obviously digital vernier to do this

as im getting worried now that my head may be scrap and getting the engine built soon

#60

PassionFord Post Troll

Join Date: Apr 2004

Location: West Sussex

Posts: 3,174

Likes: 0

Received 0 Likes

on

0 Posts

i think it is measured from top face (cam side) to bottom face . has to be measured in a few places to make sure its the same thickness all over

Karl , what does it cost to get the meat put back on the head ? are there any downsides to having it done ?

Karl , what does it cost to get the meat put back on the head ? are there any downsides to having it done ?

#61

Norris Motorsport

PJ,

The method I use involves stress relieving the head during the welding process as well as having the head pre heated(I don't want to say what I do as thats giving the game away) but it results in a very hard head face and is totally reliable.

The method I use involves stress relieving the head during the welding process as well as having the head pre heated(I don't want to say what I do as thats giving the game away) but it results in a very hard head face and is totally reliable.

#62

Originally Posted by frog

Stu, just thinking about it all again, I am not sure we talk about the same thing when we talk about decompression plates...

If I understand correctly, when the head is skimmed, it looses a given amount of metal, and the overall depth of the "combustion area" in the head reduces. A decompression plate as I understand it, would recover this depth loss.

If I understand correctly, when the head is skimmed, it looses a given amount of metal, and the overall depth of the "combustion area" in the head reduces. A decompression plate as I understand it, would recover this depth loss.

#63

0-60 in 17 seconds (eek)

Join Date: Apr 2004

Location: Berkshire

Posts: 6,717

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Stu @ M Developments

Whilst the decompression plate will restore lost compression, it will by its very nature still increase the squish clearance by raising the cylinder head itself to a higher plane and as such is undesireable.

If say, 0.5 mm had been removed from the head, and the decompression plate was that same thickness, would it affect the squish area as you suggest ?

#64

Originally Posted by frog

Originally Posted by Stu @ M Developments

Whilst the decompression plate will restore lost compression, it will by its very nature still increase the squish clearance by raising the cylinder head itself to a higher plane and as such is undesireable.

If say, 0.5 mm had been removed from the head, and the decompression plate was that same thickness, would it affect the squish area as you suggest ?

The diagram above may help to show how a spacer plate will move the heads squish area upwards away from teh pistons, thus increasing the squish clearance.

Does that help?

#65

............

Best thread on here for ages. I'v often wondered about skimming and it's effects. Never knew about squish. Top work to Stu and Karl and everyone who asked good questions. This is what makes the site brilliant for me

#66

0-60 in 17 seconds (eek)

Join Date: Apr 2004

Location: Berkshire

Posts: 6,717

Likes: 0

Received 0 Likes

on

0 Posts

mmmm, not sure I do get it....

Would that be because the head isn't actually flat in that area, again, helping to concentrate the fuel mixture as close to the plug tip as possible ? A decompression plate would raise the head, but in a straight up direction, therefore not reproducing the slope in the head's combustion area ?

Would that be because the head isn't actually flat in that area, again, helping to concentrate the fuel mixture as close to the plug tip as possible ? A decompression plate would raise the head, but in a straight up direction, therefore not reproducing the slope in the head's combustion area ?

#67

PassionFord Post Whore!!

Originally Posted by Stu @ M Developments

Originally Posted by frog

Originally Posted by Stu @ M Developments

Whilst the decompression plate will restore lost compression, it will by its very nature still increase the squish clearance by raising the cylinder head itself to a higher plane and as such is undesireable.

If say, 0.5 mm had been removed from the head, and the decompression plate was that same thickness, would it affect the squish area as you suggest ?

The diagram above may help to show how a spacer plate will move the heads squish area upwards away from the pistons, thus increasing the squish clearance.

Does that help?

So are the cylinder holes completely round in these plates? I am guessing so, then I understand the problem.

If they had the same shape as the head, would that make it all OK?

#68

0-60 in 17 seconds (eek)

Join Date: Apr 2004

Location: Berkshire

Posts: 6,717

Likes: 0

Received 0 Likes

on

0 Posts

Steve, I guess the decomp. plate is just like a thick gasket, so all the edges are square, hence my question above.

Strange how an innocent question turns into this

Strange how an innocent question turns into this

#70

PassionFord Post Whore!!

Join Date: May 2003

Location: Wiltshire UK

Posts: 3,795

Likes: 0

Received 0 Likes

on

0 Posts

Just as an 'interesting' aside...

I used to do a bit with Talbot Avengers and Sunbeams - the 1.6 pushrod engine has half the combustion chamber in the cylinder.. the piston stops well short of the block deck, absolutely no squish area whatsoever! They can make fair power (in their day anyway) but the ignition advance curve to achieve it is wild - ours had max advance of 48 degrees!

the piston stops well short of the block deck, absolutely no squish area whatsoever! They can make fair power (in their day anyway) but the ignition advance curve to achieve it is wild - ours had max advance of 48 degrees!

I used to do a bit with Talbot Avengers and Sunbeams - the 1.6 pushrod engine has half the combustion chamber in the cylinder..

the piston stops well short of the block deck, absolutely no squish area whatsoever! They can make fair power (in their day anyway) but the ignition advance curve to achieve it is wild - ours had max advance of 48 degrees!

the piston stops well short of the block deck, absolutely no squish area whatsoever! They can make fair power (in their day anyway) but the ignition advance curve to achieve it is wild - ours had max advance of 48 degrees!

#71

Norris Motorsport

Indeed Rich, in essence the more efficient a combustion chamber design the lower the required ignition for MBT conditions. (MBT = minimum spark advance for best torque). This ultimately comes about by two main factors, these being spark plug location in the chamber and the chamber design and size.

Strangely though the effect on potential bhp has little to do with chamber design. It's all about efficiency for fuel economy and emissions these days!

Strangely though the effect on potential bhp has little to do with chamber design. It's all about efficiency for fuel economy and emissions these days!

#72

I've found that life I needed.. It's HERE!!

Originally Posted by frog

mmmm, not sure I do get it....

Would that be because the head isn't actually flat in that area, again, helping to concentrate the fuel mixture as close to the plug tip as possible ? A decompression plate would raise the head, but in a straight up direction, therefore not reproducing the slope in the head's combustion area ?

Would that be because the head isn't actually flat in that area, again, helping to concentrate the fuel mixture as close to the plug tip as possible ? A decompression plate would raise the head, but in a straight up direction, therefore not reproducing the slope in the head's combustion area ?

Adding a decomp plate now makes them further apart, so not "squishing" the mixture as much as it should do:

**this is my understanding of what has been said in this post**

#74

Too many posts.. I need a life!!

Join Date: Jul 2003

Posts: 852

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Karl

PJ,

The method I use involves stress relieving the head during the welding process as well as having the head pre heated(I don't want to say what I do as thats giving the game away) but it results in a very hard head face and is totally reliable.

The method I use involves stress relieving the head during the welding process as well as having the head pre heated(I don't want to say what I do as thats giving the game away) but it results in a very hard head face and is totally reliable.

after mapping, must admit andy fisher was a bit sceptical about this head repairing process

after mapping, must admit andy fisher was a bit sceptical about this head repairing process cheers steve

#75

0-60 in 17 seconds (eek)

Join Date: Apr 2004

Location: Berkshire

Posts: 6,717

Likes: 0

Received 0 Likes

on

0 Posts

Here's how I understand it...

In the picture above, the decomp. plate only replaces the same amount of material that was removed by the skim(s).

However, because the walls of the plate are vertical, the squish area has changed shape.

Over to you stu...

In the picture above, the decomp. plate only replaces the same amount of material that was removed by the skim(s).

However, because the walls of the plate are vertical, the squish area has changed shape.

Over to you stu...

#76

just finding my feet

see this is gonna turn into the mapping thread that i nolonger understand and so i nolonger read it

im with stu so far but thinking the same was as frogs explanation

im with stu so far but thinking the same was as frogs explanation

#77

PassionFord Post Whore!!

Join Date: May 2003

Location: Wiltshire UK

Posts: 3,795

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by frog

Here's how I understand it...

In the picture above, the decomp. plate only replaces the same amount of material that was removed by the skim(s).

However, because the walls of the plate are vertical, the squish area has changed shape.

Over to you Stu...

In the picture above, the decomp. plate only replaces the same amount of material that was removed by the skim(s).

However, because the walls of the plate are vertical, the squish area has changed shape.

Over to you Stu...

#78

PassionFord Post Troll

Join Date: Apr 2004

Location: West Sussex

Posts: 3,174

Likes: 0

Received 0 Likes

on

0 Posts

when we talk about skimming a head , we are only talking about .0000eleventy millionth of a gnats cock , surely a thin flimsy bit of metal cant be a good idea aswell as a head gasket

#79

PassionFord Post Whore!!

Join Date: Aug 2004

Location: Kent

Posts: 4,364

Likes: 0

Received 0 Likes

on

0 Posts

With YB's people worry too much

Look at it this way...a STD 4x4 or 2wd YB can take 400bhp no bothers...a 4x4 can take 500bhp no bothers...who gives a fook about height of head..especially in a sub 400 engine!!!

Look at it this way...a STD 4x4 or 2wd YB can take 400bhp no bothers...a 4x4 can take 500bhp no bothers...who gives a fook about height of head..especially in a sub 400 engine!!!

#80

PassionFord Post Whore!!

Join Date: May 2003

Location: Wiltshire UK

Posts: 3,795

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by ImaRacing 700

With YB's people worry too much

Look at it this way...a STD 4x4 or 2wd YB can take 400bhp no bothers...a 4x4 can take 500bhp no bothers...who gives a fook about height of head..especially in a sub 400 engine!!!

Look at it this way...a STD 4x4 or 2wd YB can take 400bhp no bothers...a 4x4 can take 500bhp no bothers...who gives a fook about height of head..especially in a sub 400 engine!!!