My Fiecos, Now breaking my Xr2tt. 18-7-09

#202

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Originally Posted by StickerPaul

Got some donut action from last years Brunters Daddy Thrash if you want me to send you a copy mate.

Yes please, that would be good to see

#206

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Originally Posted by jayRS

oh well, was looking forward to seeing some pic's of her again.

you taking it to ford fair at all?

you taking it to ford fair at all?

#216

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

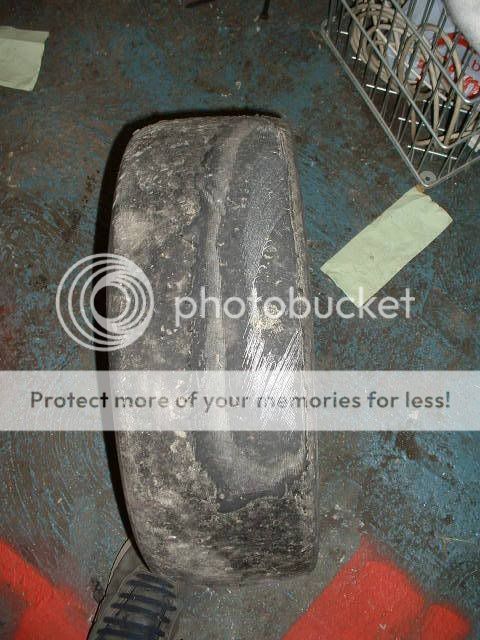

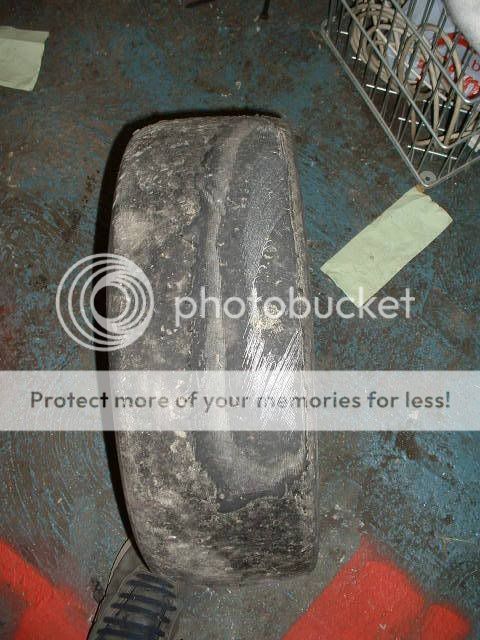

Picked up a spare set of 4 Zetec S wheels (same as i run on road)

fitted with part worn Avon 170/550/15 slicks. (thanks Simon, #13 off here)

Perfect for trackdays.

Measured both a Avon slick 3/4 worn, and a Dunlop 195/45 15 road tyre with 4mm tread, both fitted to Zetec S rims, and pumped up.

O/A hieght = 551mm Slick, 544mm Road tyre,

O/A width = 185mm Slick, 195mm Road tyre,

Tread width = 170mm slick, 165mm Road tyre.

Aiming to Go to a Trackday in the xr2tt @ Lydden Hill, Kent on the 22nd of July.

Need to,

Build and fit a gated Sump to cure oil surge problem,

Refit my Mocal 16 row oil cooler, i took off 3 years ago.

Fit EGT gauge, (boss already fitted in down pipe)

Modifie, and fit a Reno 5 turbo carb, and rejet,

Replace Valve springs,followers and check cam for wear,

(as its running noisie, so i think the cam's fukced itself due to oil surge problem),

Design and make front Castor adjusters, and set to 2.5 neg camber, and 3-5 degree castor, and set toe,

Shim out rear beam, to add Neg camber, and set toe.

So got my work cut out, but should fly once all done.

fitted with part worn Avon 170/550/15 slicks. (thanks Simon, #13 off here)

Perfect for trackdays.

Measured both a Avon slick 3/4 worn, and a Dunlop 195/45 15 road tyre with 4mm tread, both fitted to Zetec S rims, and pumped up.

O/A hieght = 551mm Slick, 544mm Road tyre,

O/A width = 185mm Slick, 195mm Road tyre,

Tread width = 170mm slick, 165mm Road tyre.

Aiming to Go to a Trackday in the xr2tt @ Lydden Hill, Kent on the 22nd of July.

Need to,

Build and fit a gated Sump to cure oil surge problem,

Refit my Mocal 16 row oil cooler, i took off 3 years ago.

Fit EGT gauge, (boss already fitted in down pipe)

Modifie, and fit a Reno 5 turbo carb, and rejet,

Replace Valve springs,followers and check cam for wear,

(as its running noisie, so i think the cam's fukced itself due to oil surge problem),

Design and make front Castor adjusters, and set to 2.5 neg camber, and 3-5 degree castor, and set toe,

Shim out rear beam, to add Neg camber, and set toe.

So got my work cut out, but should fly once all done.

#217

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Ok today i took sump off, and Just finished making a baffle/gate system,

Its a trail attempt, but Should do the trick,

Here's my trackday wheels and Avon slicks

Its a trail attempt, but Should do the trick,

Here's my trackday wheels and Avon slicks

#220

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Been out and tested the sump,

And its alot better on right hand corners, braking and accelarating,

But left hand corner's are still the same, oil pressure dropping to 30psi from 60psi,

So gonna have to try again

And its alot better on right hand corners, braking and accelarating,

But left hand corner's are still the same, oil pressure dropping to 30psi from 60psi,

So gonna have to try again

#221

PassionFord Post Whore!!

Joined: Jul 2004

Posts: 4,276

Likes: 0

From: isle of wight (K.O.P 2006 mother fucker!)

nice one mate, dropped it, sorted it and refitted it and test it all in a red hot summers day, nice one

have to give me some details of it as i might do mine before i refit it

have to give me some details of it as i might do mine before i refit it

#222

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Yeah sure,

But need to sort it better, As its doing it on road tyres, and public roads,

So dont stand a chance on a track with Slicks, and alot more corner forces..

But need to sort it better, As its doing it on road tyres, and public roads,

So dont stand a chance on a track with Slicks, and alot more corner forces..

#224

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Tonight i been out hard testing for 10 minutes around a local track (the loop) , and even tho there still was surge on left handers, i didn't get any problem with tappets colapsing like i used to.

Yesterday, i set the car up in my garage, so it was level all round

Then i measured, 4 wheel Toe, camber and castor all round

It come out like this

Front, modded camber, and poly bushes.

toe = 2mm out,

camber n/s = -2' 30", o/s = -2' 15"

castor n/s = +0' 30", o/s = +0' 23"

Rear, Still std bushes and beam.

Toe, n/s = in 2mm, o/s = out 3mm = total in 1mm toe out.

camber, n/s = -0' 8", o/s = -0' 11"

After a day of playing with the suspension to day,

including

- shorterning the tie bars by 17mm each side, making new washers and fitting new poly bushes,

- cutting and welding the n/s tie bar to miss the gearbox casing,

- cutting the front arches and body kit to stop any tyre scrub ( as now the wheel sits 2 mm away from front of the arch)

- going for a drive to settle all mod's and bushes.

- Checking Toe and adjusting to no toe, checking camber and castor.

- and finally going for a hard test drive round the local track ( the loop)

It does seem to understeer less, but it still does round roundabouts whilst pushing it.

The setting now sit at

Front,

0 toe,

camber n/s = -1' 38", o/s = -1' 23"

castor n/s = +3' 00", o/s = +2' 45"

Rear, Still std bushes and beam.

Toe, n/s = in 2mm, o/s = out 3mm = total in 1mm toe out.

camber, n/s = -0' 8", o/s = -0' 11"

So now i'm gonna put more camber on fronts, and fit new poly bushes on rear and space beam out to get even toe of 0 toe, and put camber to -1' 30"

Yesterday, i set the car up in my garage, so it was level all round

Then i measured, 4 wheel Toe, camber and castor all round

It come out like this

Front, modded camber, and poly bushes.

toe = 2mm out,

camber n/s = -2' 30", o/s = -2' 15"

castor n/s = +0' 30", o/s = +0' 23"

Rear, Still std bushes and beam.

Toe, n/s = in 2mm, o/s = out 3mm = total in 1mm toe out.

camber, n/s = -0' 8", o/s = -0' 11"

After a day of playing with the suspension to day,

including

- shorterning the tie bars by 17mm each side, making new washers and fitting new poly bushes,

- cutting and welding the n/s tie bar to miss the gearbox casing,

- cutting the front arches and body kit to stop any tyre scrub ( as now the wheel sits 2 mm away from front of the arch)

- going for a drive to settle all mod's and bushes.

- Checking Toe and adjusting to no toe, checking camber and castor.

- and finally going for a hard test drive round the local track ( the loop)

It does seem to understeer less, but it still does round roundabouts whilst pushing it.

The setting now sit at

Front,

0 toe,

camber n/s = -1' 38", o/s = -1' 23"

castor n/s = +3' 00", o/s = +2' 45"

Rear, Still std bushes and beam.

Toe, n/s = in 2mm, o/s = out 3mm = total in 1mm toe out.

camber, n/s = -0' 8", o/s = -0' 11"

So now i'm gonna put more camber on fronts, and fit new poly bushes on rear and space beam out to get even toe of 0 toe, and put camber to -1' 30"

#227

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Cheers lads,

Any pics of car? but i will need the car to do them, but pics/ drawings of what you need, and i could you a idea of how much.

Originally Posted by "luke89

im just chnagin the spec of the fez and need a custom down pipe and boost pipes , what sorta price would this cost me ?

Any pics of car? but i will need the car to do them, but pics/ drawings of what you need, and i could you a idea of how much.

#228

not atm mate will get some pics with everything in mock up place will be next week some time , if ur xr2tt is runnign a t3 it will prob be the same down pipe as that lol , boost pipes have to go under the front valance  but there will be holes cut out for them or i would have went for silocon

but there will be holes cut out for them or i would have went for silocon

but there will be holes cut out for them or i would have went for silocon

but there will be holes cut out for them or i would have went for silocon

#235

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

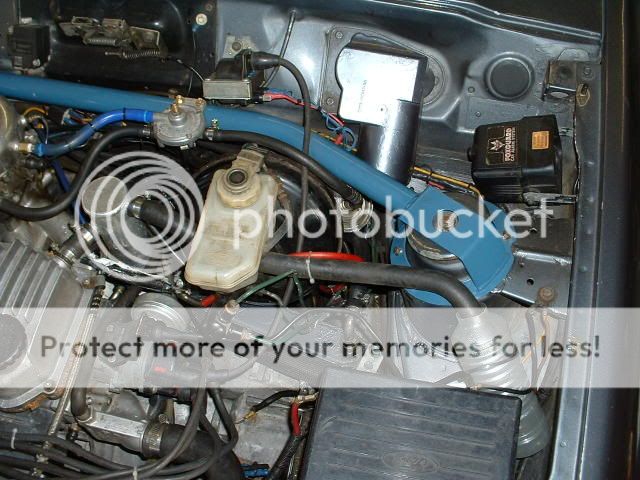

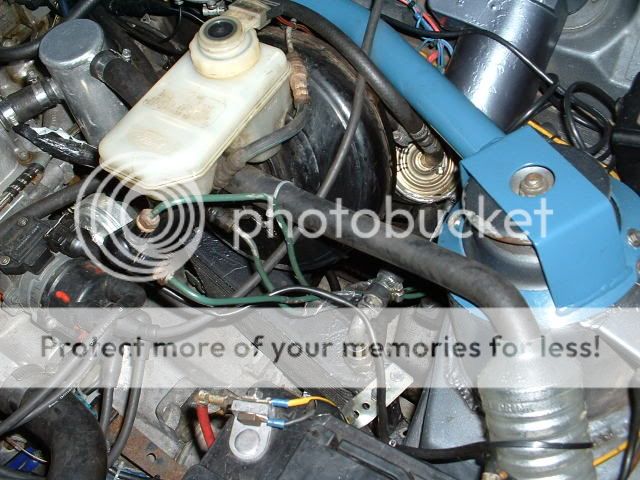

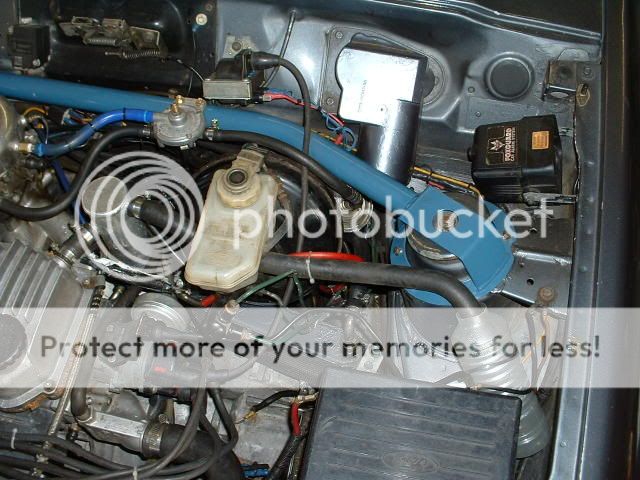

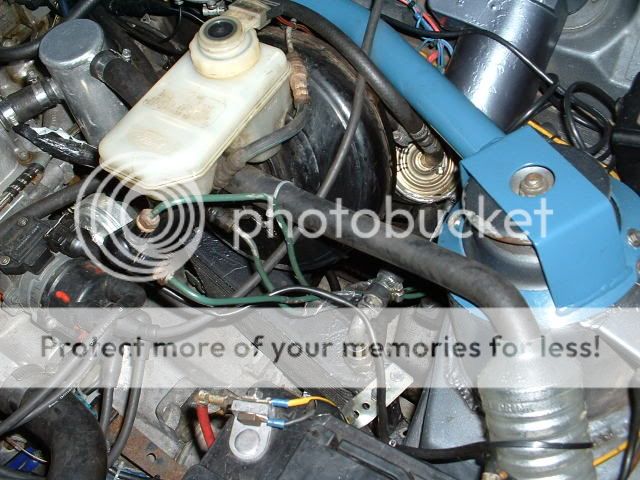

Ok, small update.

Here's a pic of the cossie last week looking very un cared for,

On my tt,

i fitted a 16 row mocal oil cooler,

changed the brake fluid, and fitted new front ferodo pads

2 weeks ago i done a Lydden hill Trackday in my tt, on 22/7/06

had a good day,

Run it at 18psi for the first 5 sessions, done 1 session at 23 psi, and the last 2 sessions at 14 psi.

Car behaved, except a few little problem, i run a 51.39 PB on my lap timer in my tt

Carb was flooding left hander, so only half throttle could be used till half way up the hill,

Avon slick Tyres i was using werent warming up till the last couple of laps of the session, so times got faster and faster till the end of each sessions.

Coolant temps too high allday. Even removed the Stat on 3rd session, and didn't change anything, By 7 mins into the sessions the fan had cut it, and didn't cut out till 5-10mins after the session had ended.

But understeer was very present, My brother was also doing it in his Pulser, But on the last session he took mine out, and couldn't believe the amount of under steer, (as he always sed his has bad underesteer)

I got the pressure's correct after the 4th session, so the tyres were even temps across the tyres ( or well as even as they would get)

But suspension needs changin,

Tyre pressures hot were

F n/s 27psi, 18.5psi cold, temps 73-79oC

F o/s 24psi, 16psi cold, temps 71-77oC

R n/s 23.5psi, 20psi cold, temps all 51oC

R o/s 21psi, 17.5psi cold, temps 45-49 oC

My front o/s slick at the end of the day, was checked to sessions before the end, and was fine. but my brother drove it on the last session, and locked the front wheels going into the hair pin once.

Here's a pic of the cossie last week looking very un cared for,

On my tt,

i fitted a 16 row mocal oil cooler,

changed the brake fluid, and fitted new front ferodo pads

2 weeks ago i done a Lydden hill Trackday in my tt, on 22/7/06

had a good day,

Run it at 18psi for the first 5 sessions, done 1 session at 23 psi, and the last 2 sessions at 14 psi.

Car behaved, except a few little problem, i run a 51.39 PB on my lap timer in my tt

Carb was flooding left hander, so only half throttle could be used till half way up the hill,

Avon slick Tyres i was using werent warming up till the last couple of laps of the session, so times got faster and faster till the end of each sessions.

Coolant temps too high allday. Even removed the Stat on 3rd session, and didn't change anything, By 7 mins into the sessions the fan had cut it, and didn't cut out till 5-10mins after the session had ended.

But understeer was very present, My brother was also doing it in his Pulser, But on the last session he took mine out, and couldn't believe the amount of under steer, (as he always sed his has bad underesteer)

I got the pressure's correct after the 4th session, so the tyres were even temps across the tyres ( or well as even as they would get)

But suspension needs changin,

Tyre pressures hot were

F n/s 27psi, 18.5psi cold, temps 73-79oC

F o/s 24psi, 16psi cold, temps 71-77oC

R n/s 23.5psi, 20psi cold, temps all 51oC

R o/s 21psi, 17.5psi cold, temps 45-49 oC

My front o/s slick at the end of the day, was checked to sessions before the end, and was fine. but my brother drove it on the last session, and locked the front wheels going into the hair pin once.

#236

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

3 days ago i took the suspension apart, so i could rise the TCA mounting at the chassie, so the tca is slopping down, so harder it corners the more camber is added,

where as up till now it run the opposite way due to being lowered 75mm at the front.

End result,

O/S front,

chassie TCA mounting holes has been moved up 16mm, and out 10mm,

Tie bar has been shortened a total of 24mm.

N/S front,

Chassie TCE mounting holes been moved up 18mm, and out 10mm,

Tie bar has been shortened a toal of 26mm.

The reason why i did different amounts for each side is because

The tie bars are different, so had to do it to get the same amount of castor each side.

And the chassie holes are different to get the TCA's sitting the same, as well as to help once the driver sat in it.

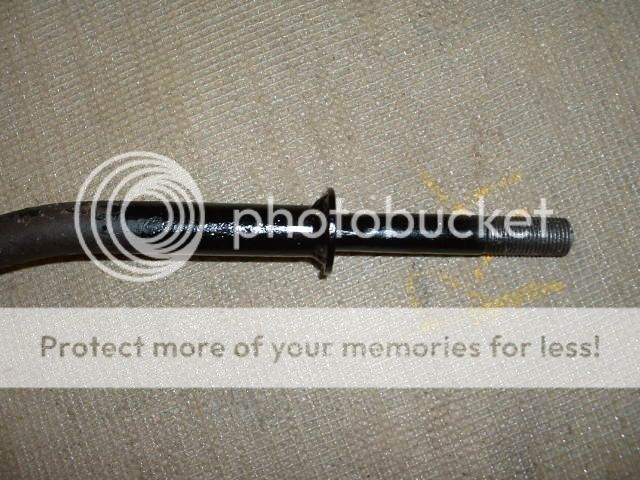

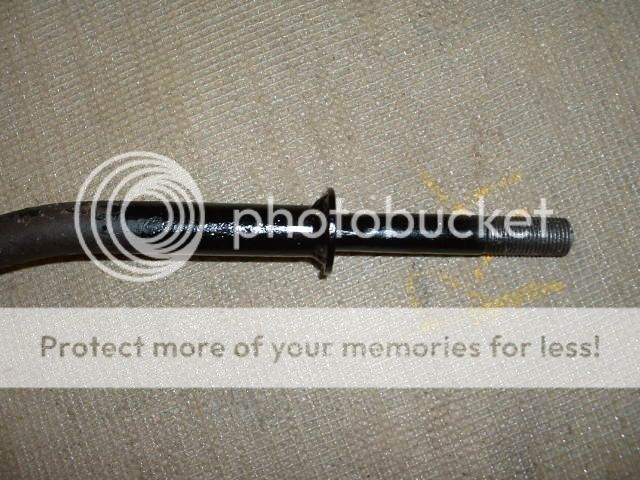

Heres some pic's of my work and mod's.

Cut down Tie bar, and new H/D washers to stop them bending like std ones do,

Where i had to mod the N/S tie bar to miss the gearbox,

My modded Tie bars and TCA's

My modded TCA's, 1st i had to cut, and strengthen them to miss the chassie where i haved the chassie mounting higher, then i had to cut and strentghen them so they where 20mm further forward, so they would mount with the new shortered Tie bars with out adding strain to the TCA mounting bush, and then slot the hole to line up with the Tie bar.

The new, higher mounted TCA's.

Next mod, will be to fit insiti adjusters on the TCA's when i get a set.

Heres a pic with the car back on the floor.

Some major arch removal had to be done to stop rubbing.

where as up till now it run the opposite way due to being lowered 75mm at the front.

End result,

O/S front,

chassie TCA mounting holes has been moved up 16mm, and out 10mm,

Tie bar has been shortened a total of 24mm.

N/S front,

Chassie TCE mounting holes been moved up 18mm, and out 10mm,

Tie bar has been shortened a toal of 26mm.

The reason why i did different amounts for each side is because

The tie bars are different, so had to do it to get the same amount of castor each side.

And the chassie holes are different to get the TCA's sitting the same, as well as to help once the driver sat in it.

Heres some pic's of my work and mod's.

Cut down Tie bar, and new H/D washers to stop them bending like std ones do,

Where i had to mod the N/S tie bar to miss the gearbox,

My modded Tie bars and TCA's

My modded TCA's, 1st i had to cut, and strengthen them to miss the chassie where i haved the chassie mounting higher, then i had to cut and strentghen them so they where 20mm further forward, so they would mount with the new shortered Tie bars with out adding strain to the TCA mounting bush, and then slot the hole to line up with the Tie bar.

The new, higher mounted TCA's.

Next mod, will be to fit insiti adjusters on the TCA's when i get a set.

Heres a pic with the car back on the floor.

Some major arch removal had to be done to stop rubbing.

#237

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

The way i measure my, toe, camber and castor, is all done on the cheap.

firstly i level the ground off in my garage, using boards, i then drive the car onto them,

the front wheels also site on home made Turning plates (not in pic's as made them at the weekend), and the rears are siting on boards to keep the car level all round.

i then made 2 stands, which are made to the same width, and designed to have string laid between them, the string has wieghts on them to keep them tensioned,

The strings are then placed in TRUE parrel with all 4 hubs on the car, by measureing to the hubs.

i then measure accurately from the string to the front and rear of each rim ( wheels have to be straight)

This Give me the 4 wheels tracking.

To measure the camber i use 2 devices i brought from demon tweaks, all in all about £80 -90. One is a camber/castor plub gauge, the other is called a Toe string gauge.

i place them on the wheels like the pic below, and read the measure ment for camber, and do this on each wheel.

To measure the castor, is abit more complexed, as each front wheel needs to be turned 20 degrees on each lock, and then the measurement worked out from both readings.

To do this i had to make a set of turning plates for the steering to be able to turn on the spot, with out resistance and pressure on any bush/mount.

To measure the 20 degree lock, i have made a template i use, i set the template up on the floor parrell with the car using the Tracking strings, then turn on each lock till its at 20 degrees from straight, to do this i use a straight rule against the tyre about 100mm above ground, so the tyre is in its true form (as at bottom the wieght of the car puts a bulge in the tyre) Then eye thro the rule to the template,

It might sound un accurate, but i've tested it back to back, and get the same results each time. But i will once sorted the car, send it to a mate who will check it all on his works 4 wheel laser allignment setup (over £15k worth)

firstly i level the ground off in my garage, using boards, i then drive the car onto them,

the front wheels also site on home made Turning plates (not in pic's as made them at the weekend), and the rears are siting on boards to keep the car level all round.

i then made 2 stands, which are made to the same width, and designed to have string laid between them, the string has wieghts on them to keep them tensioned,

The strings are then placed in TRUE parrel with all 4 hubs on the car, by measureing to the hubs.

i then measure accurately from the string to the front and rear of each rim ( wheels have to be straight)

This Give me the 4 wheels tracking.

To measure the camber i use 2 devices i brought from demon tweaks, all in all about £80 -90. One is a camber/castor plub gauge, the other is called a Toe string gauge.

i place them on the wheels like the pic below, and read the measure ment for camber, and do this on each wheel.

To measure the castor, is abit more complexed, as each front wheel needs to be turned 20 degrees on each lock, and then the measurement worked out from both readings.

To do this i had to make a set of turning plates for the steering to be able to turn on the spot, with out resistance and pressure on any bush/mount.

To measure the 20 degree lock, i have made a template i use, i set the template up on the floor parrell with the car using the Tracking strings, then turn on each lock till its at 20 degrees from straight, to do this i use a straight rule against the tyre about 100mm above ground, so the tyre is in its true form (as at bottom the wieght of the car puts a bulge in the tyre) Then eye thro the rule to the template,

It might sound un accurate, but i've tested it back to back, and get the same results each time. But i will once sorted the car, send it to a mate who will check it all on his works 4 wheel laser allignment setup (over £15k worth)

#239

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Originally Posted by jayRS

good little read there mate, lets see how far out if any the wheels will be on the machine, none i bet.

As long as i'm carefull on setting it up, and checking the geometry, it shouldn't be out.

But will be good to see if it is.

#240

PassionFord Post Whore!!

Joined: Jul 2004

Posts: 4,276

Likes: 0

From: isle of wight (K.O.P 2006 mother fucker!)

when i fitted a new ball joint years ago it pushed the passange wheel in about 10 mm (this was cos i replaced the frst ball joint with a different one due to camber etc after lowering) and tracking was way out on the passanger side, adjusted it with a bit of wood across the rim and a rule, just matched it to the drivers side that already had a short ball joint on, got it rough right, drove fine and was about 1-2mm out when i got it tracked half hour later.

it came out better than when i tried to use them fucking drive on trackers (you know the sort?) on my xr2 many years ago

it came out better than when i tried to use them fucking drive on trackers (you know the sort?) on my xr2 many years ago