where to get an exhaust manifold refaced ?

#1

Thread Starter

10K+ Poster!!

iTrader: (4)

Joined: Jun 2006

Posts: 10,211

Likes: 415

From: st neots cambridgeshire

tubular manifold warped by 3mm on both ends of the mounting flange, its an odd shape 6 branch turbo banana bunch looking manifold with external wastegate hanging out the side, im trying to find someone who would have the clamping capability to hold it in a mill, there must be someone out there who does them isnt there ?

Last edited by scoooby slayer; 18-10-2012 at 06:45 PM.

#4

PassionFord Post Whore!!

iTrader: (11)

Joined: May 2004

Posts: 5,640

Likes: 33

From: Solihull near Birmingham

Had the same thing happen to my Cossie tubular manifold, but couldn't find anyone that could hold it due to the shape.

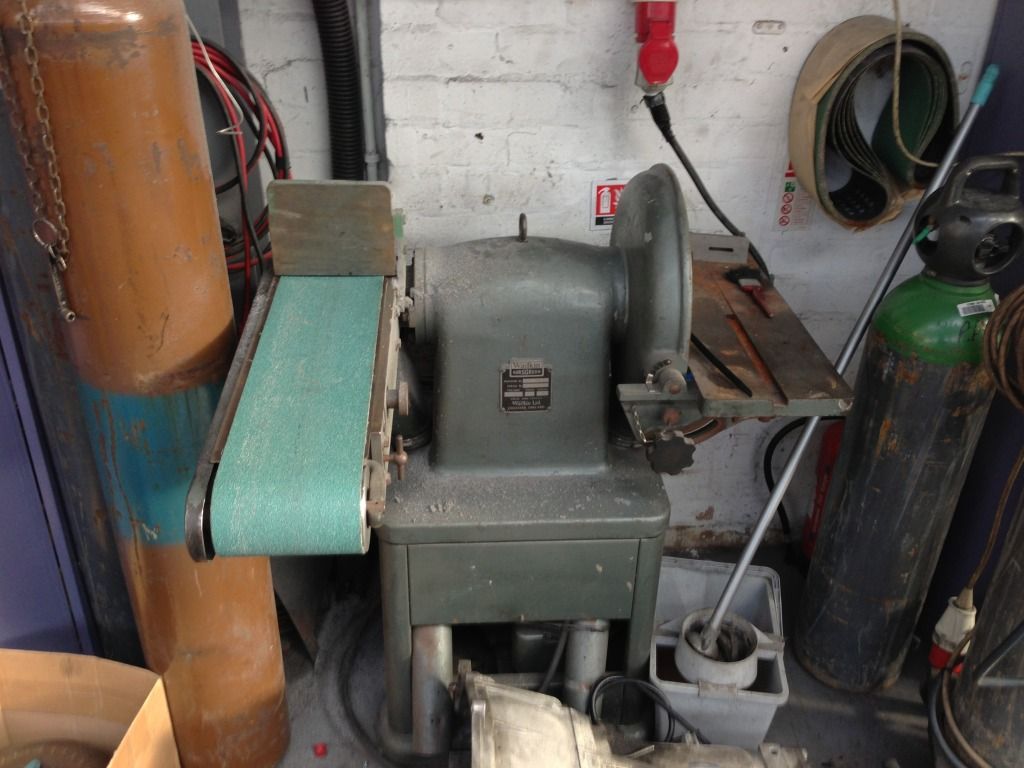

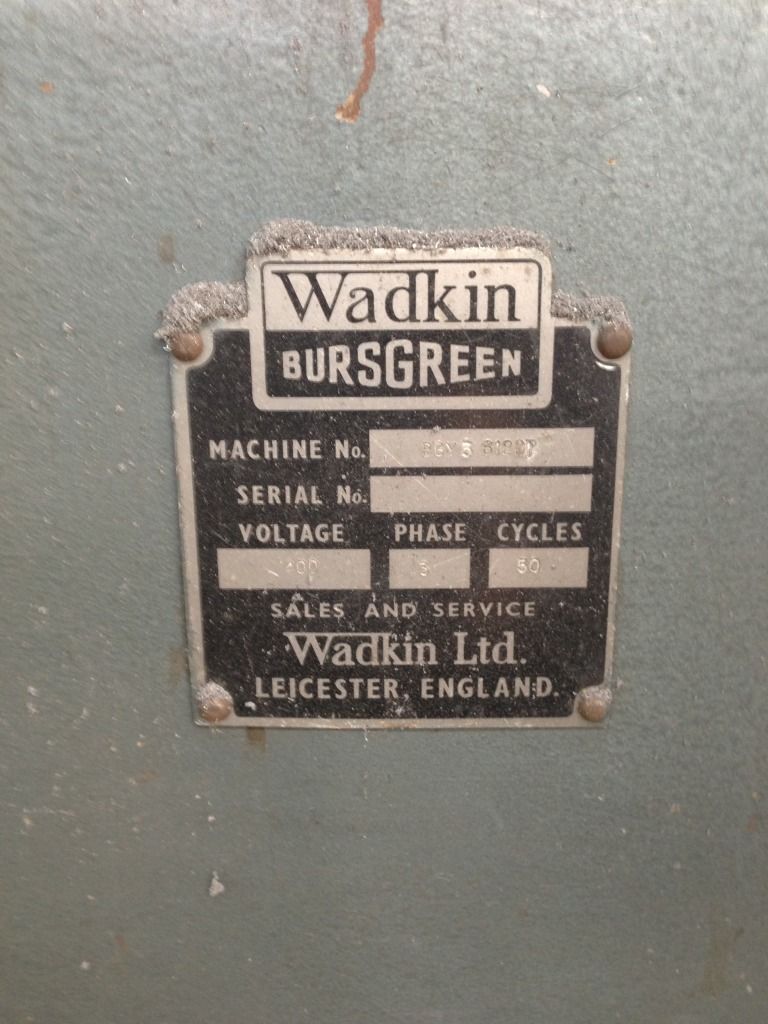

Had it done on a large table top industrial belt sander in the end.

Rich

Had it done on a large table top industrial belt sander in the end.

Rich

#6

Thread Starter

10K+ Poster!!

iTrader: (4)

Joined: Jun 2006

Posts: 10,211

Likes: 415

From: st neots cambridgeshire

im not cutting it no way, in my opinion it has done most of its warping now so i just want to get it squared off which means 3mm off the middle and it will be flat, i will find someone to do it but if someone knew someone who does this sort of thing it could be done alot quicker, im running out of time fast for some pod fun this year lol

Trending Topics

#8

why dont you get a piece off inch plate,drill wholes in it to match the manifold bolt holes and clamp it down with a 6mm packer in the middle of the manifold flange,then heat it up in the middle and slowly tighten the end bolts down until you have taken the 3mm of warping out off it,just a idea if you carnt find anyone to machine it for you,it might sound a bit of a bodge but it does work.

#9

Thread Starter

10K+ Poster!!

iTrader: (4)

Joined: Jun 2006

Posts: 10,211

Likes: 415

From: st neots cambridgeshire

why dont you get a piece off inch plate,drill wholes in it to match the manifold bolt holes and clamp it down with a 6mm packer in the middle of the manifold flange,then heat it up in the middle and slowly tighten the end bolts down until you have taken the 3mm of warping out off it,just a idea if you carnt find anyone to machine it for you,it might sound a bit of a bodge but it does work.

#10

i'm not that teech savvy but shouldn't each branch off the manifold have a separately cut flange so they can be clamped individually, then use a turbo hanger/damper to help support the weight?

#11

Can you fab up a jig to hold it secure to make it easy for a company to face it ?

it would need to be sturdy and best welded together, but you could just cut it off afterwards.

I used to have a guy that did stuff like that for me with no problems or hassles at all. Yet when you went to normal machine shops they all said it was near impossible and they couldnt do it.

More like they are just thick or cant be arsed.

Have you tried contacting some exhaust fabricators to see if they can help ?

it would need to be sturdy and best welded together, but you could just cut it off afterwards.

I used to have a guy that did stuff like that for me with no problems or hassles at all. Yet when you went to normal machine shops they all said it was near impossible and they couldnt do it.

More like they are just thick or cant be arsed.

Have you tried contacting some exhaust fabricators to see if they can help ?

#12

Thread Starter

10K+ Poster!!

iTrader: (4)

Joined: Jun 2006

Posts: 10,211

Likes: 415

From: st neots cambridgeshire

Can you fab up a jig to hold it secure to make it easy for a company to face it ?

it would need to be sturdy and best welded together, but you could just cut it off afterwards.

I used to have a guy that did stuff like that for me with no problems or hassles at all. Yet when you went to normal machine shops they all said it was near impossible and they couldnt do it.

More like they are just thick or cant be arsed.

Have you tried contacting some exhaust fabricators to see if they can help ?

it would need to be sturdy and best welded together, but you could just cut it off afterwards.

I used to have a guy that did stuff like that for me with no problems or hassles at all. Yet when you went to normal machine shops they all said it was near impossible and they couldnt do it.

More like they are just thick or cant be arsed.

Have you tried contacting some exhaust fabricators to see if they can help ?

i guess i could get it where i want it and weld some legs and a base block on it.

ive done abit of turning but literally naff all milling as it broke not long after we got it

#13

making up a rigid frame and welding the manifold to it shouldnt require any specialist work.

It may not be pretty, but as long as it holds the flange rigid to be milled or faced by some means, that's all you need.

The other alternative is to have new flanges cut and weld this onto the manifold after cutting off the warped ones.

That would be DIY'able if you have the inclination and welder

I know a guy who can waterjet you out flanges at a very sensible price

It may not be pretty, but as long as it holds the flange rigid to be milled or faced by some means, that's all you need.

The other alternative is to have new flanges cut and weld this onto the manifold after cutting off the warped ones.

That would be DIY'able if you have the inclination and welder

I know a guy who can waterjet you out flanges at a very sensible price

#15

My place could probably do it, but would need to see it properly first

the even better news is that we're only down the road

http://www.cambridge-rebores.co.uk/

the even better news is that we're only down the road

http://www.cambridge-rebores.co.uk/

#17

Thread Starter

10K+ Poster!!

iTrader: (4)

Joined: Jun 2006

Posts: 10,211

Likes: 415

From: st neots cambridgeshire

once its flat as long as everything will still fit it will be fine im sure.

the picture isnt the actual manifold just a reference similar hks manifold pic.

#18

I certainly wouldnt want individual flanges. Plus the fact the pipes turn downwards on exiting the head, this should also allow for some expansion and contraction during use without putting too much pressure on the flange.

#20

Can you not get some 3mm shims made up?

Or a 2mm shim with a gasket either side?

I had my 2wd cossie exhaust slimmed, did the head flange, trouser flange, both sides of the trouser section and the turbo housing.

It cost me £70 at my local machine shop i use, he quite often does inlets/exhaust refacing.

Im sure he could do yours but hes not quick.

Or a 2mm shim with a gasket either side?

I had my 2wd cossie exhaust slimmed, did the head flange, trouser flange, both sides of the trouser section and the turbo housing.

It cost me £70 at my local machine shop i use, he quite often does inlets/exhaust refacing.

Im sure he could do yours but hes not quick.

#21

Advanced PassionFord User

iTrader: (7)

Joined: Nov 2004

Posts: 2,361

Likes: 2

From: Holywood, N.ireland

Any good machine shop should be able to fab something up to hold that.

You should see some of the stuff the machine shops come up with to hold parts we design that dont have any flat surfaces and are 100% machined.

You should see some of the stuff the machine shops come up with to hold parts we design that dont have any flat surfaces and are 100% machined.

#22

They should be able to. Most just wont bother their arse though.

I had manifolds done ages ago. Mate in the Railways did them no problem at all.

I then tried to get a well known local place to do them a few years later....Such a nightmare. He did get them done and then charged me a fortune stating it took hours to get them set up etc.

Load of balls. Using their brains it could have been done easily in a few minutes.

I had manifolds done ages ago. Mate in the Railways did them no problem at all.

I then tried to get a well known local place to do them a few years later....Such a nightmare. He did get them done and then charged me a fortune stating it took hours to get them set up etc.

Load of balls. Using their brains it could have been done easily in a few minutes.

#23

Thread Starter

10K+ Poster!!

iTrader: (4)

Joined: Jun 2006

Posts: 10,211

Likes: 415

From: st neots cambridgeshire

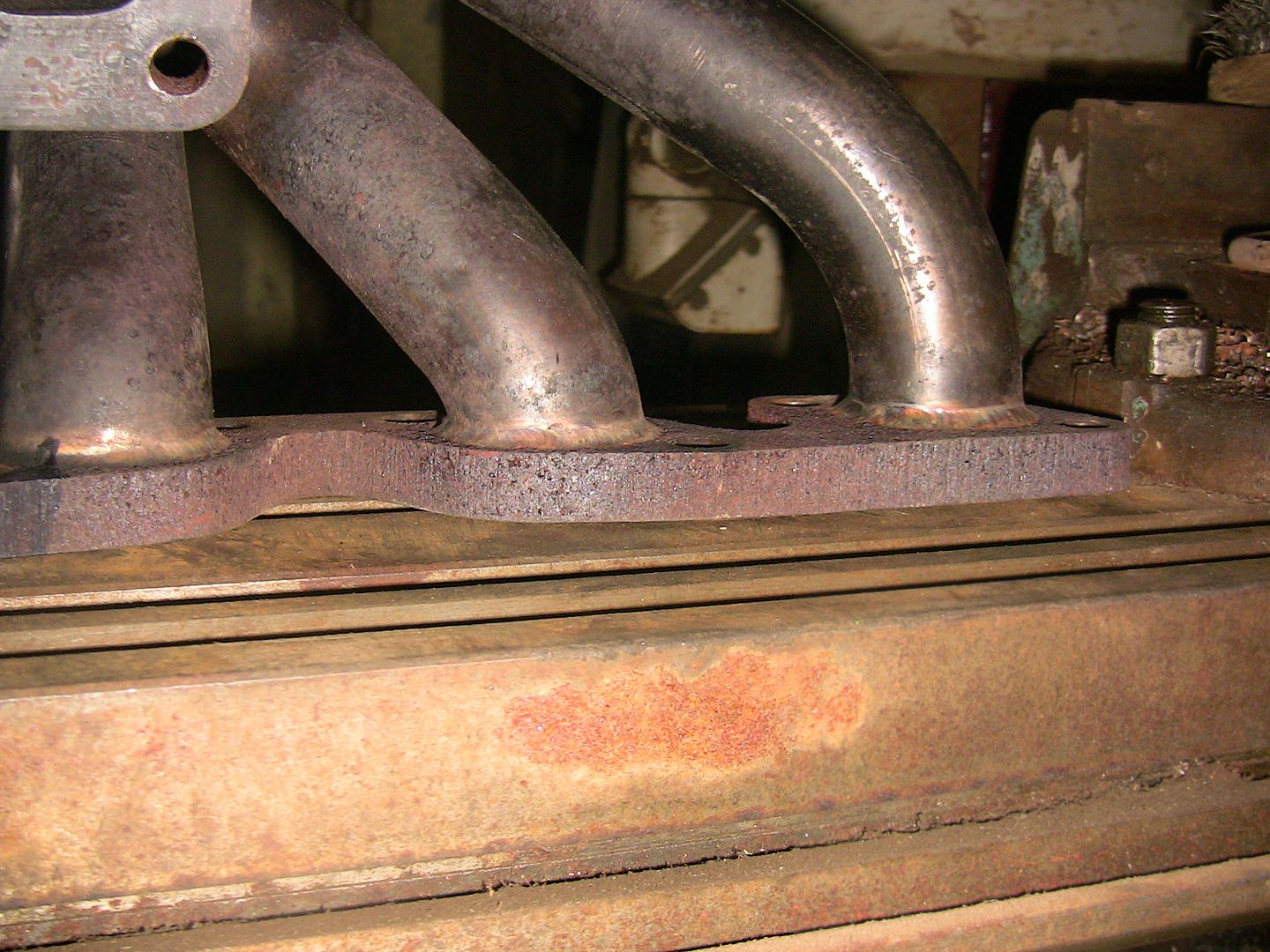

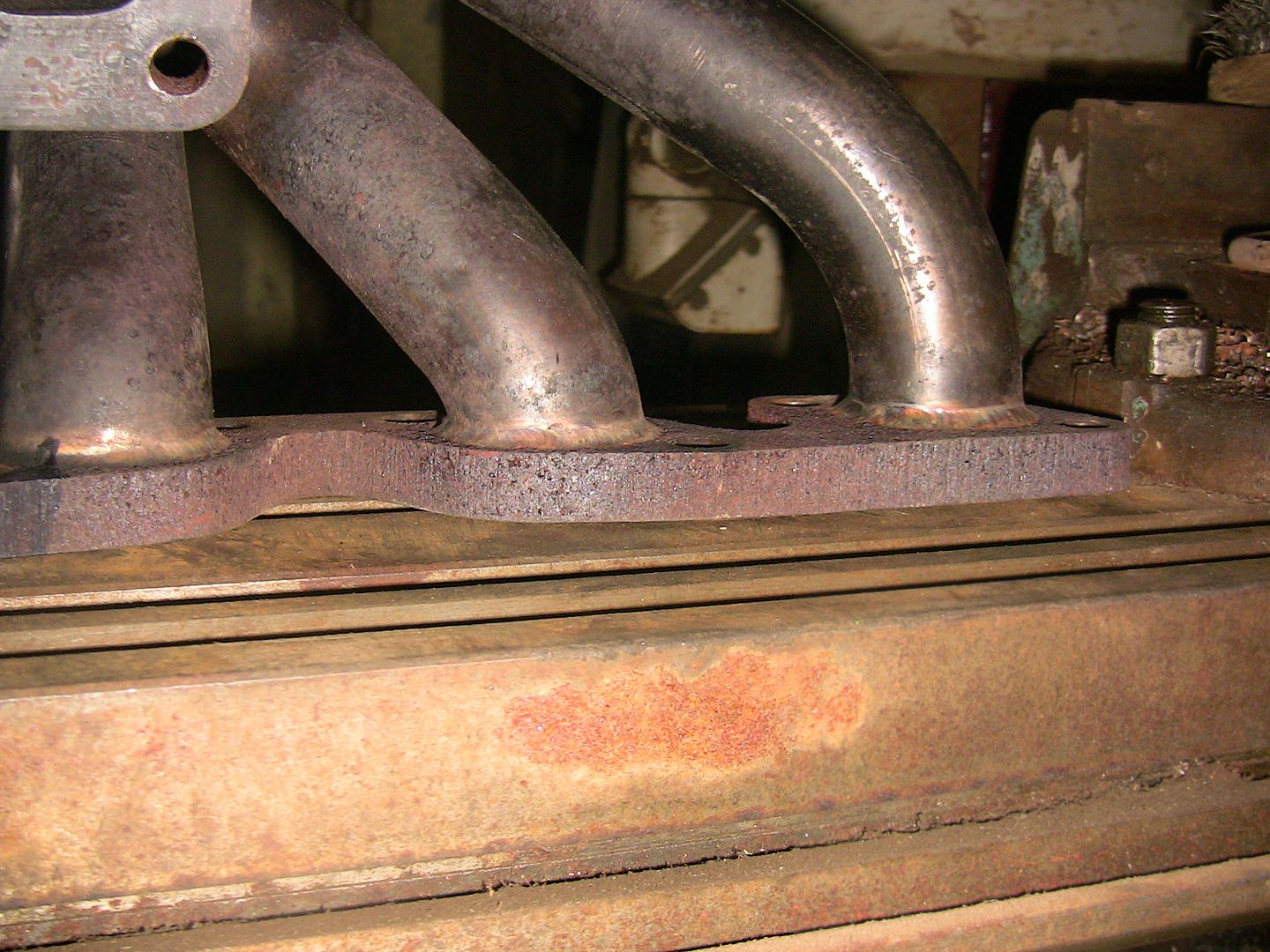

the pic above is just a generic pic, my hks manifold has had the vband flange cut off and a t4 footplate welded on, heres some pics shows extent of warping on the 2 end pics where ive got the manifold held flat on my bridgeport mill bed, and the black marked area is the area that isnt warped, so i need it setting up in a jig so the mill is dead square to the black area then taking down all over approx 3mm to square it off.

#24

There are a few DIY options you could try.

1. Cut it into 3 x 2 port sections and see if that will allow it to clamp straight. Although it may make it worse.

2. Leave as a single piece and bolt it to a spare head or solid chunk of steel. And cut some of the pipes where they meet the flange and re-weld with the flange secured flat.

I definitely wouldnt cut it into 6 separate flanges. Maybe 3 x 2, or 2 x 3 would help a little though.

1. Cut it into 3 x 2 port sections and see if that will allow it to clamp straight. Although it may make it worse.

2. Leave as a single piece and bolt it to a spare head or solid chunk of steel. And cut some of the pipes where they meet the flange and re-weld with the flange secured flat.

I definitely wouldnt cut it into 6 separate flanges. Maybe 3 x 2, or 2 x 3 would help a little though.

#25

Thread Starter

10K+ Poster!!

iTrader: (4)

Joined: Jun 2006

Posts: 10,211

Likes: 415

From: st neots cambridgeshire

well ive had it on a steel gurder as a straight edge, with a 1mm raiser on the straight edge and heated it and clamped it down, i started with a 3mm raise at each end, it now has a 1mm raise at each end with a 0.5mm kink where the bend was but the kink is inbetween ports anyways so irrelevant, im sure the manifold will pull in 1mm, and i have a stock nissan gasket which is 1.3mm thick and plyable so it will give more than a multi layer steel.

im going to take it to the welder in the morning and see what he thinks, im sure it will go now though

im going to take it to the welder in the morning and see what he thinks, im sure it will go now though

Last edited by scoooby slayer; 19-10-2012 at 04:30 PM.

#26

i'm not having a go chap but am interested to know whether this one was built by a "known" garage/tuner? After the bodges you found on the supra (that were charged top dollar for!) it makes you wonder how much of the work that's turned out by "top" tuning firms (HKS in this case for the fannymould) and/or the dudes bolting it together ain't what it should be.......

#29

Thread Starter

10K+ Poster!!

iTrader: (4)

Joined: Jun 2006

Posts: 10,211

Likes: 415

From: st neots cambridgeshire

well its blowing again on number 6 again, ive got no margin for error so ive decided i want it machineing.

ive made a flat base and got it spirit level square it bolts to it with the t4 turbo flange.

if it needs anything to clamp to it can just be welded to my base plate now.

im hopeing now ive done that any machine shop should be able to skim it easy like a cylinder head.

ive made a flat base and got it spirit level square it bolts to it with the t4 turbo flange.

if it needs anything to clamp to it can just be welded to my base plate now.

im hopeing now ive done that any machine shop should be able to skim it easy like a cylinder head.

Last edited by scoooby slayer; 27-10-2012 at 01:48 PM.

#31

I would think the actual manifold flange would need welded to a solid structure for it to be machined. Using the tubes for support they will flex when the cutting head is passing over it

You'll just have to weld it up then cut them off again.

Although if it can be surface ground that might be easier ?

You'll just have to weld it up then cut them off again.

Although if it can be surface ground that might be easier ?

#34

Thread Starter

10K+ Poster!!

iTrader: (4)

Joined: Jun 2006

Posts: 10,211

Likes: 415

From: st neots cambridgeshire

I would think the actual manifold flange would need welded to a solid structure for it to be machined. Using the tubes for support they will flex when the cutting head is passing over it

You'll just have to weld it up then cut them off again.

Although if it can be surface ground that might be easier ?

You'll just have to weld it up then cut them off again.

Although if it can be surface ground that might be easier ?

#39

PassionFord Post Whore!!

iTrader: (11)

Joined: May 2004

Posts: 5,640

Likes: 33

From: Solihull near Birmingham

I was there from 13:30 til 16:00 they don't go in till late on a saturday but they are usually there from 10:00.

Least you're getting it sorted mate.

Here's the photo's of the Dyno Torques Belt Sander:

Rich