cossie fuel pump wiring (results)

#1

Thread Starter

PassionFord Post Troll

iTrader: (8)

Joined: Dec 2006

Posts: 3,478

Likes: 3

From: oxford

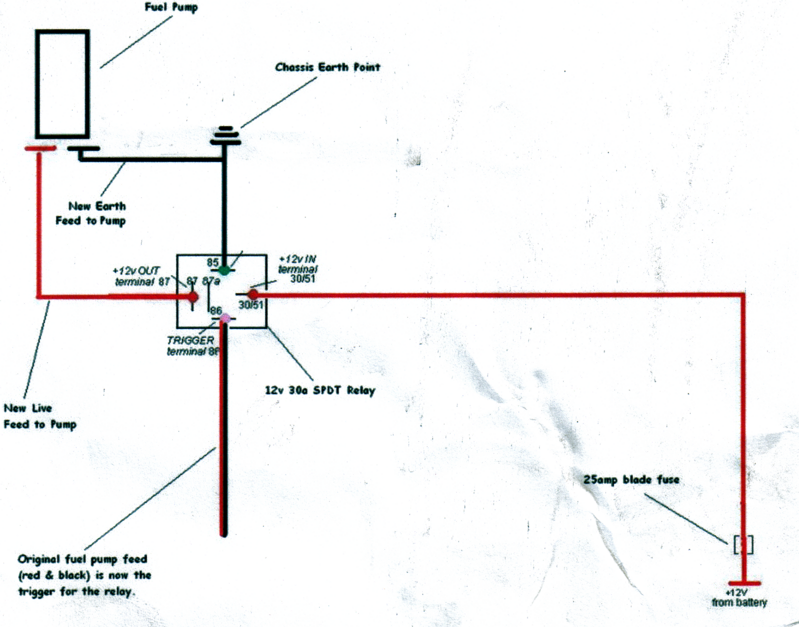

Just to make sure what is the relay everyone uses when re-wiring the fuel pump, what amp ?, type, spdt ?, also what thickness of wire etc

Last edited by coswurv; 24-05-2008 at 02:10 PM.

#3

Thread Starter

PassionFord Post Troll

iTrader: (8)

Joined: Dec 2006

Posts: 3,478

Likes: 3

From: oxford

well no help from anyone on here,same as usual if your face dont fit, but for anyone who cares, 13.22 at the batt on tickover and 11.07 before re-wire which dropped considerably when the light etc where on, 13.22 at the batt and 13.17 at the pump after re-wire so a vast improvement,

#4

Well done, and there is a thread already on pg1 of general discussion about it, which then has links to another couple of good threads about it!

Where did you earth it, and did you make a new earth for the pump?

Where did you earth it, and did you make a new earth for the pump?

Trending Topics

#13

A std SPNO relay is the one to use, NOT SPDT, but some seem confused betwen SPDT and SPSO, which are TOTALLY DIFFERENT.

The cable used above is way OTT.

There is no point in earthing here, as it STILL relies on the original BATTERY cables having no high resistance, which they will, due to age etc.

A much better option is to wire earth straight to the battery, as you have to take a LIVE from there anyway, it takes little more time.

You only need a wire suffecient to carry the CONTINUOUS current, which from memory is 13 amps on full load from a group a pump.

This being the case, 32/020 or 28/030 is MORE than up to the job.

It is pointless using a SPSO, as there is no switch just a close of circuit.

I mount these in a relay holder, and secure behind the rear n/s seat back up top as there is already a 8mm hole there that is ideal for the through bolt of the relay holder.

Just make sure anywhere subject to vibration you do NOT solder, but CRIMP with Adhesive lined heat shrink over it.

tabetha

The cable used above is way OTT.

There is no point in earthing here, as it STILL relies on the original BATTERY cables having no high resistance, which they will, due to age etc.

A much better option is to wire earth straight to the battery, as you have to take a LIVE from there anyway, it takes little more time.

You only need a wire suffecient to carry the CONTINUOUS current, which from memory is 13 amps on full load from a group a pump.

This being the case, 32/020 or 28/030 is MORE than up to the job.

It is pointless using a SPSO, as there is no switch just a close of circuit.

I mount these in a relay holder, and secure behind the rear n/s seat back up top as there is already a 8mm hole there that is ideal for the through bolt of the relay holder.

Just make sure anywhere subject to vibration you do NOT solder, but CRIMP with Adhesive lined heat shrink over it.

tabetha

#14

Glad this came up, saves me looking for the old one. I have never had problems with the voltage to my pump but im soon going to be running two extra pumps, i already have a amp power wire run through the car would this be ok to use as the feed.

#15

i always solder behind the crimp, this does not in anyway effect the strength of the cable, as its still solder free where it leaves the terminal.

tried and tested, never had a broken cable,or loose wire...

where as,i did have a few crimped joints fail

i also renewed the std earth wire on the battery, and have never in all my years seen high resistance through a car body?

tried and tested, never had a broken cable,or loose wire...

where as,i did have a few crimped joints fail

i also renewed the std earth wire on the battery, and have never in all my years seen high resistance through a car body?

Last edited by JTECH James; 24-05-2008 at 06:26 PM.

#16

Too many posts.. I need a life!!

iTrader: (1)

Joined: Jul 2006

Posts: 666

Likes: 0

From: Haggis Hunting

OVERKILL OR WHAT RYAN???

Ford build there looms overated as standard, but obviously time takes it toll on any cars wiring. So often am I being asked how to re-wire a Cosworth fuel pump. I would place bets on the new relay and re-locate pump earth sorted the problem. Both me and Ryan use wire rated to 30 Amp for fuel pumps, If you measure the current of a fuel pump running it is approx 9 Amps. The Fuse is rated at 20 Amps to prevent it blowing when the pump starts to turn which can pull 20 Amps for a milli second.

And before any know it all "shoots me down" I'm offering advice, not questioning anyones comments or knowledge thank you

Ford build there looms overated as standard, but obviously time takes it toll on any cars wiring. So often am I being asked how to re-wire a Cosworth fuel pump. I would place bets on the new relay and re-locate pump earth sorted the problem. Both me and Ryan use wire rated to 30 Amp for fuel pumps, If you measure the current of a fuel pump running it is approx 9 Amps. The Fuse is rated at 20 Amps to prevent it blowing when the pump starts to turn which can pull 20 Amps for a milli second.

And before any know it all "shoots me down" I'm offering advice, not questioning anyones comments or knowledge thank you

#18

it can make the wire brittal, and break if not done correctly, crimping allows the cable to flex, but as said, i always solder begind the crimp, so the cable still flexes as normal, but is joined to the terminal by the solder rather than the crimp

#22

Too many posts.. I need a life!!

iTrader: (1)

Joined: Jul 2006

Posts: 666

Likes: 0

From: Haggis Hunting

Type 44 aircraft wire as used in all our wiring. Either 2 x 18 guage to give flexibility or single 12 guage.

The Focus WRC only uses single 16 guage!

The Focus WRC only uses single 16 guage!

Last edited by PROMETHEUS; 24-05-2008 at 10:11 PM.

#28

The ONLY reason why not to solder where vibration could be a factor is because of ACID FLUXES in the solder that weaken the joints ability to flex.

PROPER crimped connectors do NOT come undone, under normal pressure/use.

F1 teams crimp and X RAY thier connections.

NO "high resistance through a car body", but at each END of the car body where you will find CONNECTORS at the battery in the loom at relays etc you WILL find high resistance, and especially when areas are used subject to water/corrosion.

tabetha

PROPER crimped connectors do NOT come undone, under normal pressure/use.

F1 teams crimp and X RAY thier connections.

NO "high resistance through a car body", but at each END of the car body where you will find CONNECTORS at the battery in the loom at relays etc you WILL find high resistance, and especially when areas are used subject to water/corrosion.

tabetha

#31

well no help from anyone on here,same as usual if your face dont fit, but for anyone who cares, 13.22 at the batt on tickover and 11.07 before re-wire which dropped considerably when the light etc where on, 13.22 at the batt and 13.17 at the pump after re-wire so a vast improvement,

Its got nothing to do with "if your face fits" dont be such a tart

#33

Its got nothing to do with "if your face fits" dont be such a tart

#36

#37

Too many posts.. I need a life!!

Joined: May 2004

Posts: 925

Likes: 0

From: in the garage fixing yet another oil leak

The ONLY reason why not to solder where vibration could be a factor is because of ACID FLUXES in the solder that weaken the joints ability to flex.

PROPER crimped connectors do NOT come undone, under normal pressure/use.

F1 teams crimp and X RAY thier connections.

NO "high resistance through a car body", but at each END of the car body where you will find CONNECTORS at the battery in the loom at relays etc you WILL find high resistance, and especially when areas are used subject to water/corrosion.

tabetha

PROPER crimped connectors do NOT come undone, under normal pressure/use.

F1 teams crimp and X RAY thier connections.

NO "high resistance through a car body", but at each END of the car body where you will find CONNECTORS at the battery in the loom at relays etc you WILL find high resistance, and especially when areas are used subject to water/corrosion.

tabetha

often crimp connections made with cheaper tools result in joints that look good and feel good but the connector is not holding the wire properly. the crimp works by causing an interference fit between the wire and the crimp connector (effectively relying on the malleability of the copper wire) and this in turn relies of the correct pressure from the tool and the correct dies being fitted. if this does not happen then when high currents are involved such as with the fuel pump wiring, there is significant resistance which cause voltage drop and get hot and then the problem worsens.

what can also happen with cheaper crimping tools is that the crimp on the cable insulation is secure and feels good and strong when its tugged but the actual electrical part of the crimp connection is not tight.

if you dont want to pay lots of dosh for a quality tool then a crimp joint by a cheaper tool followed by solder using a 100 watt iron and small amount of solder makes the best and most reliable connection. after this stage use adhesive lined heatshrink as this gives support to the joint and counteracts any tendency for the solder to have flowed upo the wire from the joint (which is unlikley if you solder it correctly)

a good way to check the fuel pump wiring is to connect a couple of headlamp bulbs across the pump and measure the pump voltage then. simply measuring the voltage across the pump at idle tells you nothing as the pump current is much lower when idling. the high current of the bulbs simulates the load the pump will take under high boost conditions.

every single connection between the battery and the pump will cause a small voltage drop. in most cases these connections will have more impact on the actual voltage the pump sees than what thickness cable was used to wire it.

#39

Too many posts.. I need a life!!

Joined: May 2004

Posts: 925

Likes: 0

From: in the garage fixing yet another oil leak

and one final point about buying wire. on several occasions when ive bought cable rated as eg 4mm, it turns out not to be 4 but 2.6 or something like that because even though the correct number of strands are present as advertised, they are actually thinner than quoted!

Thread

Thread Starter

Forum

Replies

Last Post

kosienutter

General Car Related Discussion.

31

22-08-2015 09:55 AM

CabrioTurbo

General Car Related Discussion.

1

01-08-2015 11:04 AM