R&B Motorsport Adjustable Top Mounts

#241

*** Sierra RS Custard ***

iTrader: (3)

PS

When I first described these mounts to Jaycos in my reply that got deleted when he asked how they worked, before any of us had seen the underside picture, thats EXACTLY how I said they worked, I find it amazing the manufacturers didnt do that in the first place, as its just SO obvious

When I first described these mounts to Jaycos in my reply that got deleted when he asked how they worked, before any of us had seen the underside picture, thats EXACTLY how I said they worked, I find it amazing the manufacturers didnt do that in the first place, as its just SO obvious

#242

*** Sierra RS Custard ***

iTrader: (3)

chip dont start that net warrior bullsit with me mate as it dont wash! im no diffrent on here as i am in real life am i?

Do not post on any of my topics and i will not on yours! i will not be replying even on this topic which i started and you took over as i have nothing else to say!

Do me a favor and put me on block as im sick to fucking death of this me me me atitude from you i truly wish you would just fuck off

Do not try to speak to me again as you will be talking to your self!!

Do not post on any of my topics and i will not on yours! i will not be replying even on this topic which i started and you took over as i have nothing else to say!

Do me a favor and put me on block as im sick to fucking death of this me me me atitude from you i truly wish you would just fuck off

Do not try to speak to me again as you will be talking to your self!!

Im just trying to solve the problem of how to best use (or decide not to use) this style of mount, same as Dan or anyone else, the only people making it "chip chip chip" are the people talking about me, which is not what im choosing to do unless drawn into by comments like yours here.

Last edited by Chip; 25-02-2008 at 11:47 PM.

#245

PassionFord Post Whore!!

Dan, got you now, yes, thats correct, apologies to you and Neil, I misunderstood what you were describing, Yes going right down through with those bolts and putting a nut underneath would indeed make it a lot stronger, but would then make the mount TOTALLY pointless as you wouldnt be able to adjust it with the strut in, going down and into a large ring with captive nuts or thread sections though WOULD allow the adjustment still.

Thats acutally FAR better than just helicoiling the ally in fact, so a really good suggestion that ben can implement if he keeps these mounts

Thats acutally FAR better than just helicoiling the ally in fact, so a really good suggestion that ben can implement if he keeps these mounts

i would,

make and fit the 3-5mm turret falnge washer under the turret,

then drill and tap thro the top mount adjuster bolts,

fit the longer bolt, with a nut underneath, and tack nut in place,

then remove the flange washer and tig weld a nut.

this will allow the same ease of adustement, but with added strength, the only issue, are the thread on the top mount, and thread on the turret flange washer binding against each other.

Last edited by Fiecos Dan; 25-02-2008 at 11:52 PM.

#246

*** Sierra RS Custard ***

iTrader: (3)

(you would need to just drill out the bottom mount plate slightly still though to allow the bolts to pass through it without catching on the threads)

#248

PassionFord Post Whore!!

could do, but

you are then, adding more possible movement and possible weakness, with un supported long bolt, with it all hanging on a 8mm thread of the nut.

ideally for strength,

drill thro the turret with a clearance hole, but not weld the nut on the flange washer,

then once its adjusted and set up, remove the wheel, then fit a lock nut on the end of the longer bolt under the turret.

So then its got the thread of the top mount, and a locknut, locking the two together.

you are then, adding more possible movement and possible weakness, with un supported long bolt, with it all hanging on a 8mm thread of the nut.

ideally for strength,

drill thro the turret with a clearance hole, but not weld the nut on the flange washer,

then once its adjusted and set up, remove the wheel, then fit a lock nut on the end of the longer bolt under the turret.

So then its got the thread of the top mount, and a locknut, locking the two together.

Last edited by Fiecos Dan; 25-02-2008 at 11:59 PM.

#250

*** Sierra RS Custard ***

iTrader: (3)

Dan, yeah if you dont want to keep adjusting it, that seems like a good plan.

The other option I did think, is to put a bolt right up through from the bottom, going through the bottom section, and then just put a locknut onto the top of it, that way you could do it when you fitted it up, and wouldnt have to take the wheel off.

The other option I did think, is to put a bolt right up through from the bottom, going through the bottom section, and then just put a locknut onto the top of it, that way you could do it when you fitted it up, and wouldnt have to take the wheel off.

#251

*** Sierra RS Custard ***

iTrader: (3)

Plus I suspect Dan is just coming up with solutions for the simple reason that sometimes its fun to solve a problem, even if you know there is a different problem with a better solution you could be solving instead, "just because"

#252

PassionFord Post Whore!!

i'm still gonna run my Adj TCA's, but i want top mounts for castor, as i want to keep the std ARB.

the other option i've played with, is making the ARB adjustable for Castor.

Last edited by Fiecos Dan; 26-02-2008 at 12:04 AM.

#253

Resident Wrestling Legend

iTrader: (3)

i was thinking that, if there is 20-25mm worth of metal at the top, would it not be easier to just mill out a bigger hole enough for a bolt and socket to fit onto and then use a ring at the bottom with captive nuts and adjust it that way

but it seems that overnight this problam has been answered with the same answer that i came up with but didn't post at about 3 yesterday afternoon

#254

Caraholic

iTrader: (3)

Bloody hell, I didn't expect this to be quite so long winded. I haven't got time to read all the posts, but just to clarify a few points (as I still haven't heard back from America):

1. I didn't reply to Chip's queries as I realised that he was correct as soon as I read Ben's post, but needed to let Ben advise Chip of this, rather than shooting anyone down in flames - I thought it courteous to inform Ben, so that he could be the man that he is and admit he was wrong.

2. For those that are concerned about the design, then you should also be concerned about the Ford one posted up which is mounted from the top.

3. There is a potential design flaw (although how significant this is, I am waiting to hear what the Yanks say), but it is a piece of proverbial to rectify. The four top bolts that do the adjustment of the camber are threaded all the way through the 1" thick alloy, so if anyone was worried, they could drill corresponding holes into the suspension turret to allow the mounts to be clamped all the way through like the Ford ones, and just use longer bolts than the ones supplied (which do only rely on the 1" thick alloy thread to support the car - again - I'm waiting clarification on the actual tensile strength of the alloy to see if this is as much of a problem as is perceived). Once I have heard what the American manufacturer has to see about everyone's fears, then the relevant action can be taken.

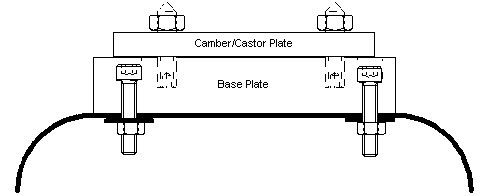

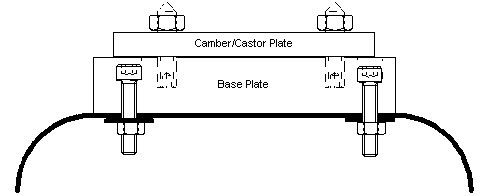

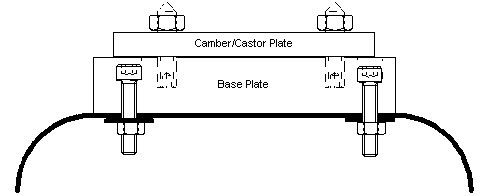

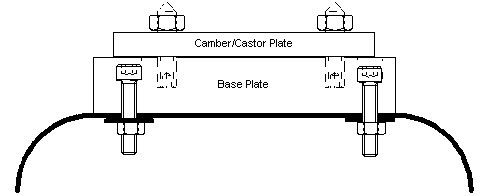

The reason for the design is that all the top mounts I have seen only allow one way adjustment (camber), this one allows two (caster AND camber - as two SEPARATE planes of adjustment). The reason for the thickness is obviously for the strength of the threads due to the design. Given the person who has designed this, I would like to think that the strength has all been tested (considering that they originate from the US, where sueing a manufacturer for faulty products is second nature), but I am of course going to ensure that all the questions are suitably answered to my own satisfaction.

Until that time, I would prefer (for my own piece of mind) if the longer bolts I suggested were used, so that any possible design flaw in the thread strength (if this exists) is negated.

1. I didn't reply to Chip's queries as I realised that he was correct as soon as I read Ben's post, but needed to let Ben advise Chip of this, rather than shooting anyone down in flames - I thought it courteous to inform Ben, so that he could be the man that he is and admit he was wrong.

2. For those that are concerned about the design, then you should also be concerned about the Ford one posted up which is mounted from the top.

3. There is a potential design flaw (although how significant this is, I am waiting to hear what the Yanks say), but it is a piece of proverbial to rectify. The four top bolts that do the adjustment of the camber are threaded all the way through the 1" thick alloy, so if anyone was worried, they could drill corresponding holes into the suspension turret to allow the mounts to be clamped all the way through like the Ford ones, and just use longer bolts than the ones supplied (which do only rely on the 1" thick alloy thread to support the car - again - I'm waiting clarification on the actual tensile strength of the alloy to see if this is as much of a problem as is perceived). Once I have heard what the American manufacturer has to see about everyone's fears, then the relevant action can be taken.

The reason for the design is that all the top mounts I have seen only allow one way adjustment (camber), this one allows two (caster AND camber - as two SEPARATE planes of adjustment). The reason for the thickness is obviously for the strength of the threads due to the design. Given the person who has designed this, I would like to think that the strength has all been tested (considering that they originate from the US, where sueing a manufacturer for faulty products is second nature), but I am of course going to ensure that all the questions are suitably answered to my own satisfaction.

Until that time, I would prefer (for my own piece of mind) if the longer bolts I suggested were used, so that any possible design flaw in the thread strength (if this exists) is negated.

Last edited by Mike Rainbird; 26-02-2008 at 08:15 AM.

#255

*** Sierra RS Custard ***

iTrader: (3)

Cheers for replying Mike, and Im glad to hear you are taking this seriously now.

If its an inch thick, then its certainly going to have a lot of tensile strength when the threads are in good order, there is no way you will rip the bolts out on first application if correctly torqued, but given the ease with which threads can be damaged in ally, I personally think that some steel inserts or helicoils would be a responsible idea, especially due to the fact that these things could potentially still be knocking around in 10 years time, and could be in the hands of people who realise as little about the implications as ben did when this thread started.

FAR more worrying still of course is the "ebay special" ones that will no doubt appear copying them too, the more I see stuff like this the more I have to concede that the germans have the right ideas with modifying with their TUV approval on everything,

I fail to see what point there is in hearing from the american manufacturer unless they will give you an official statement to questions like "how safe are these going to be with damaged threads in the ally" as thats actually the sort of thing that a responsible retailer needs to be considering when deciding if they want to be responsible for loads of these ending up ultimately in the secondhand market.

The fact they didnt bother to steel insert or helicoil them from the word go, speaks volumes about how much they are concerned about the long term use implications of these items.

(IMHO you kind of have to accept that all ally threads under load and particuarly when inregular use WILL eventually damage over time)

If its an inch thick, then its certainly going to have a lot of tensile strength when the threads are in good order, there is no way you will rip the bolts out on first application if correctly torqued, but given the ease with which threads can be damaged in ally, I personally think that some steel inserts or helicoils would be a responsible idea, especially due to the fact that these things could potentially still be knocking around in 10 years time, and could be in the hands of people who realise as little about the implications as ben did when this thread started.

FAR more worrying still of course is the "ebay special" ones that will no doubt appear copying them too, the more I see stuff like this the more I have to concede that the germans have the right ideas with modifying with their TUV approval on everything,

I fail to see what point there is in hearing from the american manufacturer unless they will give you an official statement to questions like "how safe are these going to be with damaged threads in the ally" as thats actually the sort of thing that a responsible retailer needs to be considering when deciding if they want to be responsible for loads of these ending up ultimately in the secondhand market.

The fact they didnt bother to steel insert or helicoil them from the word go, speaks volumes about how much they are concerned about the long term use implications of these items.

(IMHO you kind of have to accept that all ally threads under load and particuarly when inregular use WILL eventually damage over time)

Last edited by Chip; 26-02-2008 at 08:33 AM.

#258

Caraholic

iTrader: (3)

Obviously a belt and braces job would be to fabricate a ring insert for the bottom of the strut top, which would then give it the exact same strength as any other mount that was bolted from underneath. However, having seen the thickness of the OE strut tops, I think this may be over-kill, but it certainly can't hurt.

#259

*** Sierra RS Custard ***

iTrader: (3)

Right, so its not just longer bolts, its longer bolts and a fabricated ring? Are those going to be something you supply, or at least supply drawings for detailing thread pitch and PCD of holes etc?

Do you think there will be an issue with the bolt passing through 2 threaded sections like this that cant be rotated independantly of each other, as I dont really see how you could get the bolt to bite into both and pull both together at the same time, as thats basically not how a bolt works?

Do you think there will be an issue with the bolt passing through 2 threaded sections like this that cant be rotated independantly of each other, as I dont really see how you could get the bolt to bite into both and pull both together at the same time, as thats basically not how a bolt works?

#261

Caraholic

iTrader: (3)

Chip,

If required I can supply the ring and the bolts no problem. However, given that the majority of these are being professionally fitted by Danny B / Cosworth Specialists (and that they have only been sold to friends), I don't think I need to tell him/them that they will have to do the nut up AFTER they have torqued the bolts through the alloy top mount.

If required I can supply the ring and the bolts no problem. However, given that the majority of these are being professionally fitted by Danny B / Cosworth Specialists (and that they have only been sold to friends), I don't think I need to tell him/them that they will have to do the nut up AFTER they have torqued the bolts through the alloy top mount.

#263

*** Sierra RS Custard ***

iTrader: (3)

Chip,

If required I can supply the ring and the bolts no problem. However, given that the majority of these are being professionally fitted by Danny B / Cosworth Specialists (and that they have only been sold to friends), I don't think I need to tell him/them that they will have to do the nut up AFTER they have torqued the bolts through the alloy top mount.

If required I can supply the ring and the bolts no problem. However, given that the majority of these are being professionally fitted by Danny B / Cosworth Specialists (and that they have only been sold to friends), I don't think I need to tell him/them that they will have to do the nut up AFTER they have torqued the bolts through the alloy top mount.

Personally I would possibly consider using studs that go into the ally and are threadlocked in place, then just put nuts on the top, that way its still easy to adjust, and it means that the threads in the ally only ever need to be done up once, when you torque the stud in place initially.

Might be worth considering?

Last edited by Chip; 26-02-2008 at 09:59 AM.

#264

Resident Wrestling Legend

iTrader: (3)

If its nuts on the bottom like that, it will mean that these mounts are no longer adjustable in situ surely?

Personally I would possibly consider using studs that go into the ally and are threadlocked in place, then just put nuts on the top, that way its still easy to adjust, and it means that the threads in the ally only ever need to be done up once, when you torque the stud in place initially.

Might be worth considering?

Personally I would possibly consider using studs that go into the ally and are threadlocked in place, then just put nuts on the top, that way its still easy to adjust, and it means that the threads in the ally only ever need to be done up once, when you torque the stud in place initially.

Might be worth considering?

unless you are of course refering to putting the threaded rod into the ally first, then placing the mount on the top of the strut and then, from underneath, fixing the nuts to stop it from leaving the strut top and then fitting the rest of the gubbins on top, this way allowing for the adjustment as required without the need to move the threads in the alloy block at any time again in the future

#265

*** Sierra RS Custard ***

iTrader: (3)

Dojj, done the way I just mentioned, the ally would still be held in its existing way to the strut top, and the top adjsuters would still be the same, ie it would be NO stronger than it is now, the ONLY difference is that it would stop the ally threads being damaged over time, which is my biggest real issue with this design.

Id also put a ring underneath to re-enforce the moutning to the car though, but only on the existing bolts into the ally.

Thats for a "quick fix" that is easy to implement, its still got some issues of course, but is a big step forward from the standard mount IMHO and wouldnt actually involve a lot of hassle to do, they are going ot end up either not as user friendly or prohibitively expensive otherwise.

Id also put a ring underneath to re-enforce the moutning to the car though, but only on the existing bolts into the ally.

Thats for a "quick fix" that is easy to implement, its still got some issues of course, but is a big step forward from the standard mount IMHO and wouldnt actually involve a lot of hassle to do, they are going ot end up either not as user friendly or prohibitively expensive otherwise.

#266

Resident Wrestling Legend

iTrader: (3)

i suppose the best way to solve this problem, and the hieght issue as well would be to sandwich it between the strut top with a reinforcing plate with captive nuts essetntially welded to the underneath so you can unscrew the bolts, adjust what you need to do, then tighten them back up again

but i'm thinkin this is going to take loads more investigation and fabrication for a new design rather than just to modify what the existing set up is

but i'm thinkin this is going to take loads more investigation and fabrication for a new design rather than just to modify what the existing set up is

#267

*** Sierra RS Custard ***

iTrader: (3)

A solution doesnt actually NEED to be the perfect or ultimate one Dojj for most people to be happy with it, but it would be nice if it doesnt get massively less safe over time as the threads wear in the ally, and if it could be a bit more idiotproof than if you overtighten the bolts in ally then you lose your strut.

#269

Advanced PassionFord User

Mike,

Can you show a pic of the top mount dis-assembled, i.e with the caster/camber plate removed from the base plate?

And to clarify, the ford ones Mark showed earlier are not actually adjustable, they merely widen the top mounting dimensions contain numerous M8 high tensile bolts locating the top mount to the modifed tall turret..after being involved in several Grp'a' and wrc cars they have never been an issue on both tar and gravel cars...

Ian

Can you show a pic of the top mount dis-assembled, i.e with the caster/camber plate removed from the base plate?

And to clarify, the ford ones Mark showed earlier are not actually adjustable, they merely widen the top mounting dimensions contain numerous M8 high tensile bolts locating the top mount to the modifed tall turret..after being involved in several Grp'a' and wrc cars they have never been an issue on both tar and gravel cars...

Ian

#270

*** Sierra RS Custard ***

iTrader: (3)

Yes, the only disadvtange with doing it that way, is it being a strut out job to change the bolts, where as the studs could be done from the top, but yes from a strength point of view it has some clear additonial advantages, what I cant work out, is why they didnt do it this way in the first place, and then scrap the idea of the 6 bolts underneath, as if the 4 fail, the 6 are of no use anyway so dont really bring anything to the party anyway?

#271

Caraholic

iTrader: (3)

Mike,

Can you show a pic of the top mount dis-assembled, i.e with the caster/camber plate removed from the base plate?

And to clarify, the ford ones Mark showed earlier are not actually adjustable, they merely widen the top mounting dimensions contain numerous M8 high tensile bolts locating the top mount to the modifed tall turret..after being involved in several Grp'a' and wrc cars they have never been an issue on both tar and gravel cars...

Ian

Can you show a pic of the top mount dis-assembled, i.e with the caster/camber plate removed from the base plate?

And to clarify, the ford ones Mark showed earlier are not actually adjustable, they merely widen the top mounting dimensions contain numerous M8 high tensile bolts locating the top mount to the modifed tall turret..after being involved in several Grp'a' and wrc cars they have never been an issue on both tar and gravel cars...

Ian

#272

Caraholic

iTrader: (3)

but yes from a strength point of view it has some clear additonial advantages, what I cant work out, is why they didnt do it this way in the first place, and then scrap the idea of the 6 bolts underneath, as if the 4 fail, the 6 are of no use anyway so dont really bring anything to the party anyway?

#273

Advanced PassionFord User

Would this be a solution, countersink and bolt it right through the base plate, strut top and if necessary fit a supporting ring (personally I doubt it would need it...

Chip, rather than just providing comments, surely a guy of your obvious intelligence should have tabled a viable solution by now?

Chip, rather than just providing comments, surely a guy of your obvious intelligence should have tabled a viable solution by now?

Last edited by ian sibbert; 26-02-2008 at 11:07 AM.

#274

*** Sierra RS Custard ***

iTrader: (3)

Ian, holding the baseplate down isnt the biggest issue really, but yes that would solve that problem.

Mike, im afraid its you not me I think mate that hasnt thought out what I just said correctly.

If you have studs for the 4 adjusters into the baseplate then you can remove them easily from above!

Mike, im afraid its you not me I think mate that hasnt thought out what I just said correctly.

If you have studs for the 4 adjusters into the baseplate then you can remove them easily from above!

#275

Advanced PassionFord User

to be 100% as per OEM I think we all know the assembley needs to be beneath the turret top, the japanese cars (which I think these have been developed from) have the advantage of usually having a larger rectangular turret to house such a mount, we unfortunately dont, so it's a case of making the best of the limited space or chopping the standard turret out and welding a modifeid larger turret to carry the mount in, this would I'm sure you'd agree be unsuitable for most peoples needs, these mounts offer a half way house and with minor mods I think be fit for purpose (even without mods I personally think they'll be ok)

On the drawing ive done you could apply the same theory and coutersink upwards to hold the castor/camber plate in place.....allowing the thick alloy plate to absorb the load both ways....

On the drawing ive done you could apply the same theory and coutersink upwards to hold the castor/camber plate in place.....allowing the thick alloy plate to absorb the load both ways....

#276

Caraholic

iTrader: (3)

Would this be a solution, countersink and bolt it right through the base plate, strut top and if necessary fit a supporting ring (personally I doubt it would need it...

Chip, rather than just providing comments, surely a guy of your obvious intelligence should have tabled a viable solution by now?

Chip, rather than just providing comments, surely a guy of your obvious intelligence should have tabled a viable solution by now?

Thanks for taking some time over this, but given the concerns raised by Chip, that design looks like it is still relying on the four bolts into the alloy taking the weight of the car. So is still subject to the same concerns?

The actual design of these mounts is from three individual pieces to allow the part that supports the damper (the central piece) to move in two plains. The way it is designed is that the weight of the car is supported by the four bolts that Chip has high-lighted and these are threaded into the alloy mount (almost as per your drawing, but the thread goes all the way through, which would enable you to screw in a bolt from underneath the platform and OE strut top, so that you have a clamping effect)

Chip,

Regarding your idea of a stud, could you clarify what you mean, as I cannot visualise how this would offer any clamping from underneath, unless a nut was put on it, and if a nut was put on it, then how would this be any easier to undo with the struts in place (remembering that the alloy top mount is threaded)?

#277

*** Sierra RS Custard ***

iTrader: (3)

Mike, Im talking about keeping the mount exactly as it is now, but replacing the bolts for the adjusters with studs, just purely so that the threads in the ally only ever have to be done up once, not continually as Ben swaps between trackday and dragstrip setups etc.

Then to mount the ally baseplate, do it as it is now, but preferabley with a re-enforcing ring underneath.

Thats the quickest fix that I reckon still is a significant improvement.

NOT ideal, but will make them last longer by a big margin IMHO than to continually work the ally thread.

Then to mount the ally baseplate, do it as it is now, but preferabley with a re-enforcing ring underneath.

Thats the quickest fix that I reckon still is a significant improvement.

NOT ideal, but will make them last longer by a big margin IMHO than to continually work the ally thread.

#278

Advanced PassionFord User

Mike,

But by nut and bolting right through, you eliminate the concerns over the stength of the threads in the alloy (that's Chips main concern) after skim reading the thread...the torsional strengths of nut and bolt fixings can be controlled from a quality point of view, so once determined, the number and size would effectively safeguard the design. Studs are all very well, but sometimes provide less strength than a nut and bolt fixing. And you still run the risk of any fixing, dropping out if fitted vertially from underneath. Fitting them from above would allow the owner to quickly jack the car up (thereby allowing the strut to hang) and check the base plate fixings easily, we regulary check the M8 bolts that hold the top plates on the rally cars.....

Ian

But by nut and bolting right through, you eliminate the concerns over the stength of the threads in the alloy (that's Chips main concern) after skim reading the thread...the torsional strengths of nut and bolt fixings can be controlled from a quality point of view, so once determined, the number and size would effectively safeguard the design. Studs are all very well, but sometimes provide less strength than a nut and bolt fixing. And you still run the risk of any fixing, dropping out if fitted vertially from underneath. Fitting them from above would allow the owner to quickly jack the car up (thereby allowing the strut to hang) and check the base plate fixings easily, we regulary check the M8 bolts that hold the top plates on the rally cars.....

Ian

#279

*** Sierra RS Custard ***

iTrader: (3)

Ian, bolting right through is without doubt a better solution than the studs I have just suggested, but less easy to implement as a retro fit.

My concern with the ally threads, is more about how they age, than their initial strength which although I dont like the concept of, I accept that they no doubt ARE strong enough initially.

With a stud, the thread stays strong for a lot longer if its being adjusted a lot, especially if there is the risk people doing it up arent using a torque wrench etc, it just seems more "idiot proof" that way round.

Your solution is (of course) a technically better one though

My concern with the ally threads, is more about how they age, than their initial strength which although I dont like the concept of, I accept that they no doubt ARE strong enough initially.

With a stud, the thread stays strong for a lot longer if its being adjusted a lot, especially if there is the risk people doing it up arent using a torque wrench etc, it just seems more "idiot proof" that way round.

Your solution is (of course) a technically better one though

#280

Caraholic

iTrader: (3)

Mike, Im talking about keeping the mount exactly as it is now, but replacing the bolts for the adjusters with studs, just purely so that the threads in the ally only ever have to be done up once, not continually as Ben swaps between trackday and dragstrip setups etc.

Then to mount the ally baseplate, do it as it is now, but preferabley with a re-enforcing ring underneath.

Thats the quickest fix that I reckon still is a significant improvement.

NOT ideal, but will make them last longer by a big margin IMHO than to continually work the ally thread.

Then to mount the ally baseplate, do it as it is now, but preferabley with a re-enforcing ring underneath.

Thats the quickest fix that I reckon still is a significant improvement.

NOT ideal, but will make them last longer by a big margin IMHO than to continually work the ally thread.

I see what you're saying now

Ian,

I see what you're saying, hence why I wanted the bolts reversed. The fact that it threads into the alloy top mount and then would be pulled on by the nuts at the top should ensure no problem of dropping out I would hope. It would also resolve all the issues, rather than one.