RS1600i zetec turbo restore - update 01-05-07

#1481

i used a 6" bench grinder with wirebrush wheel that i have on the garage wall, it buffed the crud off the valves in no time

ive noticed the faces of the exhaust valves are quite badly pitted, so im going to take them into work tonight and reface them so theyre good as new

ive noticed the faces of the exhaust valves are quite badly pitted, so im going to take them into work tonight and reface them so theyre good as new

#1483

managed to reface the exhaust valves last night

to show the difference it made... here's a before and after comparison

before...

after...

should make lapping in a whole load easier

to show the difference it made... here's a before and after comparison

before...

after...

should make lapping in a whole load easier

#1494

I've found that life I needed.. It's HERE!!

Joined: Jul 2004

Posts: 1,294

Likes: 0

From: Cumbria/Preston

You bloody weirdo...who sells a car then carries on building the engine?  I was so impressed by your commitment earlier on in this thread, now I suspect you should be paying the men in white coats with the money from the car's sale!

I was so impressed by your commitment earlier on in this thread, now I suspect you should be paying the men in white coats with the money from the car's sale!

I was so impressed by your commitment earlier on in this thread, now I suspect you should be paying the men in white coats with the money from the car's sale!

I was so impressed by your commitment earlier on in this thread, now I suspect you should be paying the men in white coats with the money from the car's sale!

#1497

why not polish the valves while you're at it? i did mine a few weeks ago when rebuilding my mondy Si head... also changed the inlet valves for the 33mm blacktop ones while i was at it!

pics:

pics:

#1499

they took about 5 mins each with some 80 grit, then 180 grit. done in a pillar drill at my work, then faced with a 30 and 45 degree seat and finally the stems were polished. total time for each valve must have been about 6-8 mins

you should consider doing it if you're going to all that trouble with the bottom end! the build so far looks awesome

just a hint, the largest valve sizes for a zetec are 34mm exhaust and 30mm exhaust, available from two seperate companies. iirc, the st170 uses 33.5mm inlets and the blacktop uses 33mm ones. handy to know if you're going for ultimate power

you should consider doing it if you're going to all that trouble with the bottom end! the build so far looks awesome

just a hint, the largest valve sizes for a zetec are 34mm exhaust and 30mm exhaust, available from two seperate companies. iirc, the st170 uses 33.5mm inlets and the blacktop uses 33mm ones. handy to know if you're going for ultimate power

#1501

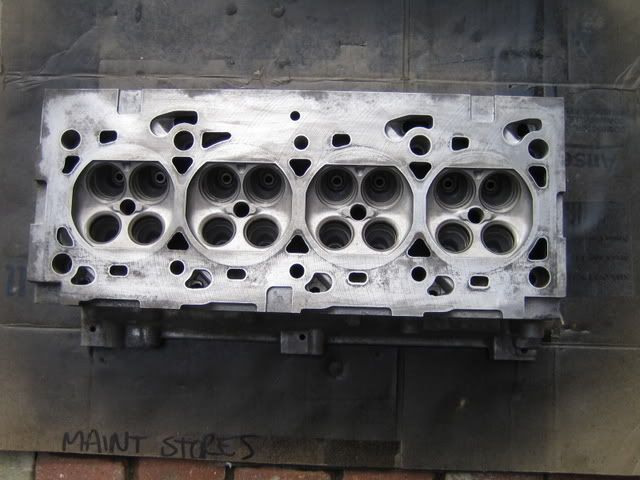

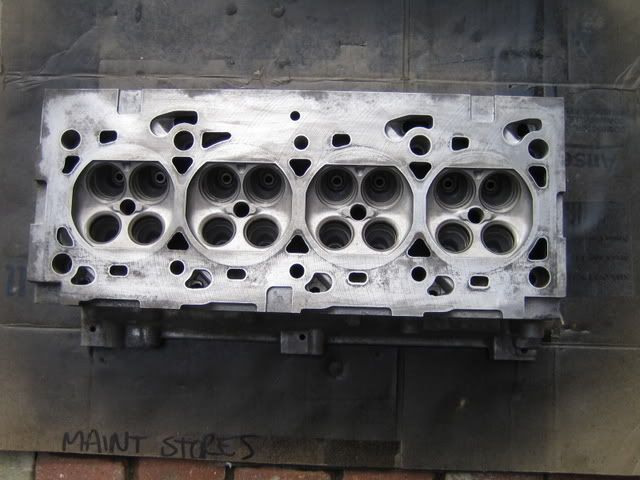

one cleaned up bare cylinder head

forgot to take pics of the valve stem oil seals, valves, valve springs etc being fitted, so you'll just have to imagine that being done

16 valves nicely in their new home

head bolted down to block with new gasket and bolts, cam followers have also been fitted

cam pulleys removed and new camshaft oil seals fitted

camshaft pulleys fitted again

its only rested on for now, but i had to stick the rocker cover on and see how it looked

im dead happy with how the builds progressing now, shouldnt be too much longer until its complete

forgot to take pics of the valve stem oil seals, valves, valve springs etc being fitted, so you'll just have to imagine that being done

16 valves nicely in their new home

head bolted down to block with new gasket and bolts, cam followers have also been fitted

cam pulleys removed and new camshaft oil seals fitted

camshaft pulleys fitted again

its only rested on for now, but i had to stick the rocker cover on and see how it looked

im dead happy with how the builds progressing now, shouldnt be too much longer until its complete

#1511

camshaft locking tool, so u keep the cams at right position for no1 piston at TDC when timing up.

my question is - how come urs works and mine didnt?! i bought the same one and it was bent - absolutely useless, wouldnt locate in both shafts :S

my question is - how come urs works and mine didnt?! i bought the same one and it was bent - absolutely useless, wouldnt locate in both shafts :S

#1513

looks like a section of a old f clamp i got in the shed ?

only a peice of stock bar aint it polished u know anymore on this 16 i ben mate

any chance you couls get some pics for me ???

drop me a pm if u like fella

only a peice of stock bar aint it polished u know anymore on this 16 i ben mate

any chance you couls get some pics for me ???

drop me a pm if u like fella

#1514

s1kid cheers

smitsturbo demolition mans right its a camshaft locking tool

demolition_man it doesnt locate in either camshaft (unless you slacken off the camshaft bearing caps, as i have done in the photo) as its too thick and just like yours it was bent, so i straightened it.

and just like yours it was bent, so i straightened it.

SafeChav

beefy-rst-2 its just a piece of crappy bar, feels a bit cheap and soft if im honest, bends dead easy, nothing like the bar we use at work. if it was a shade thinner it'd fit without having to loosen the cam caps off. what do you want pics of?

smitsturbo demolition mans right its a camshaft locking tool

demolition_man it doesnt locate in either camshaft (unless you slacken off the camshaft bearing caps, as i have done in the photo) as its too thick

SafeChav

beefy-rst-2 its just a piece of crappy bar, feels a bit cheap and soft if im honest, bends dead easy, nothing like the bar we use at work. if it was a shade thinner it'd fit without having to loosen the cam caps off. what do you want pics of?

#1515

thers 16 i of ur mates if poss bud

gary said the lad dont get online much , was hoping u could get me some piccys of it

im sure by now ur familiar with what to look for lol

much appriceated\

beef

gary said the lad dont get online much , was hoping u could get me some piccys of it

im sure by now ur familiar with what to look for lol

much appriceated\

beef

#1517

saying as the Draper camshaft locking tool was no use, i made my own

sandblasted the coilpack bracket, painted it and bolted it down along with the coil pack. pushed the core plug in the block sealing up the hole left by the breather i removed.

trial fitted the manifolds to see how they looked

its now ready to begin fabricating the new section of exhaust manifold to allow the turbo to bolt on.

tomorrow i will get the thermostat housing bolted to the head along with a new thermostat, and if i get time the cambelt/timing will be sorted.

sandblasted the coilpack bracket, painted it and bolted it down along with the coil pack. pushed the core plug in the block sealing up the hole left by the breather i removed.

trial fitted the manifolds to see how they looked

its now ready to begin fabricating the new section of exhaust manifold to allow the turbo to bolt on.

tomorrow i will get the thermostat housing bolted to the head along with a new thermostat, and if i get time the cambelt/timing will be sorted.