ZX10R turbo kit car build - update 10-08-13

#523

Regular Contributor

Join Date: Jul 2008

Location: magor, south wales

Posts: 205

Likes: 0

Received 0 Likes

on

0 Posts

Cheers Gary, it's not the best welding you'll ever see, but it's done what I wanted it to and it's not too bad for my second attempt at aluminium welding.

Aluminium feels nice to weld, it flows lovely when you get started on a run, but it goes pear shaped so much more quickly than stainless/mild steel.

I need more welding jobs to get some practice in, it's one of those things I find really enjoyable, it'd be even better if the welds looked perfect every time!

Aluminium feels nice to weld, it flows lovely when you get started on a run, but it goes pear shaped so much more quickly than stainless/mild steel.

I need more welding jobs to get some practice in, it's one of those things I find really enjoyable, it'd be even better if the welds looked perfect every time!

and i need 2 x -10 or so fittings welded into my rocker cover for my oil breather system

im slowly gathering various pieces/thicknesses of ally to practice with once i get my own welder

#524

10K+ Poster!!

Thread Starter

Thanks

That's the opinion of most people who have used R-Tech, it certainly felt that way to me when I ran up to ask questions and order my welder. I've been using the TIG set this morning to do a bit of MMA welding for one of the neighbours, it's becoming a very useful tool in the garage!

If you're wanting it done before you get yourself a welder drop me a pm, I could help you out if I've not gone back to work

When you fancying taking the plunge into the welding world?

When you fancying taking the plunge into the welding world?

#527

10K+ Poster!!

Thread Starter

#528

10K+ Poster!!

Thread Starter

The new oil pickup turned up in todays post, it's meant for a 2006/2007 CBR900RR Fireblade, but it's the perfect size and shape to be modified and used in my baffled sump.

Here it is

Here it is

Last edited by Red16; 23-03-2012 at 08:44 PM.

#529

10K+ Poster!!

Thread Starter

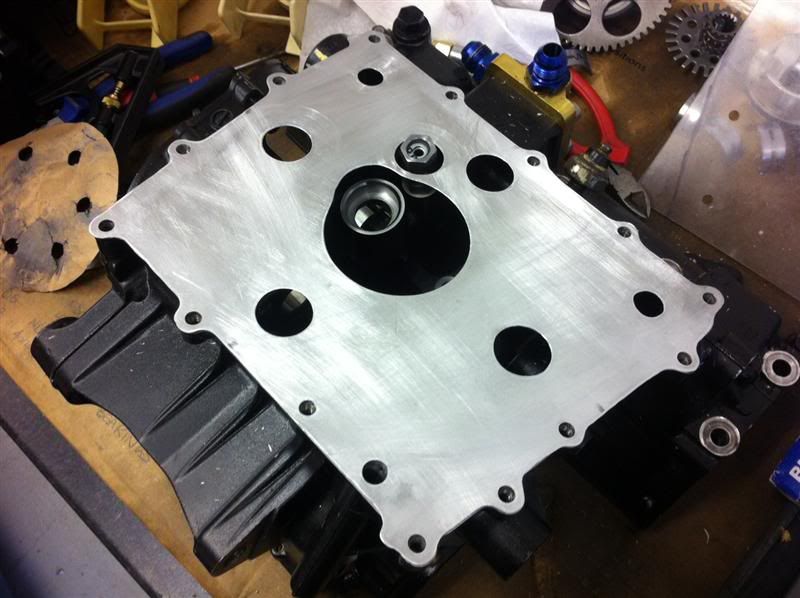

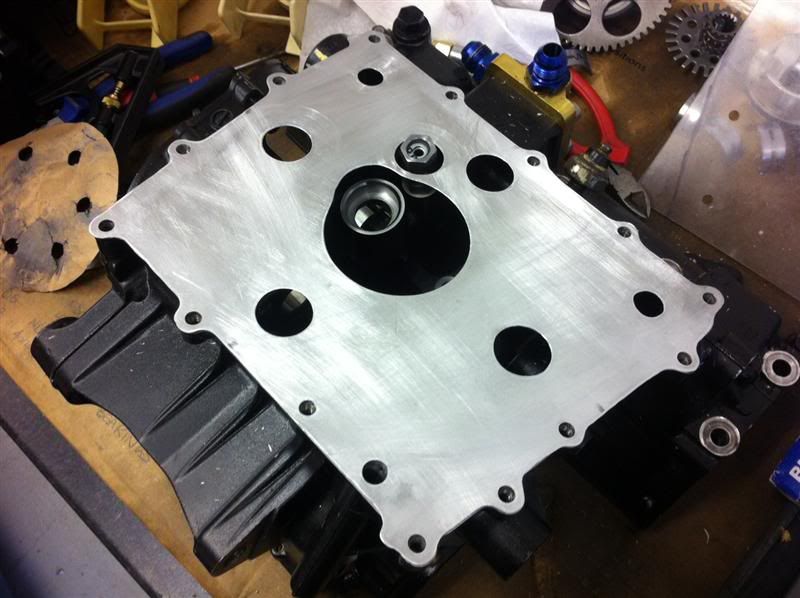

This afternoons task was to sort out a baffle plate to go between the engine and sump, I marked out and drilled the holes for the oil return and sump mounting bolts.

Here it is trial fitted to the engine to check hole spacings

It was then trimmed down to the shape of the engine/sump

With it resting on the engine it looks like this

Once the sump baffles and oil pickup are finished I will add the necessary holes in the baffle plate to suit.

Here it is trial fitted to the engine to check hole spacings

It was then trimmed down to the shape of the engine/sump

With it resting on the engine it looks like this

Once the sump baffles and oil pickup are finished I will add the necessary holes in the baffle plate to suit.

#532

10K+ Poster!!

Thread Starter

Here's the latest installment of updates...

One baffle box for the centre of the sump.

The sump was then cut to allow the baffe box to be fitted.

Here is roughly how it will look when assembled, although there will be extra baffle plates between the sump walls and the baffle box.

Once the pipework ha been fabricated, the Fireblade oil pickup will sit in the base of the sump something like this.

One baffle box for the centre of the sump.

The sump was then cut to allow the baffe box to be fitted.

Here is roughly how it will look when assembled, although there will be extra baffle plates between the sump walls and the baffle box.

Once the pipework ha been fabricated, the Fireblade oil pickup will sit in the base of the sump something like this.

#535

10K+ Poster!!

Thread Starter

I'm waiting on some tube being delivered to allow the sump to be progressed, so I decided to leave that and move onto the cylinder head.

Before stripping the head I wanted to double check the cam journal to cap clearances, so strips of plastigauge were laid across the journals

All the cam caps were fitted, bolts torqued up and then removed, this crushed the plastigauge material, the clearances measured between 0.0015" and 0.002", whcih were within manufacturers recommendation of 0.0015" and 0.0032"

Next up was the task of removing the valves, a spring compressor was used to compress and hold the valve springs

Here you can see the valve spring has been compressed and the securing collets are accessable

Using a telescopic magnet the collets were removed

With the valve spring compressor removed things look like this

The valve spring retainer was then removed

With the valve spring removed, you can see thevalve stem and valve stem oil seal

The valve them simply pushes out of the head.

The bare cylinder head

I cleaned all the deposits from the valves, here are a couple of before and after comparison photos

The valves stems were then measured, checked for damage/bending and llapped in with fine valve grinding paste

Before stripping the head I wanted to double check the cam journal to cap clearances, so strips of plastigauge were laid across the journals

All the cam caps were fitted, bolts torqued up and then removed, this crushed the plastigauge material, the clearances measured between 0.0015" and 0.002", whcih were within manufacturers recommendation of 0.0015" and 0.0032"

Next up was the task of removing the valves, a spring compressor was used to compress and hold the valve springs

Here you can see the valve spring has been compressed and the securing collets are accessable

Using a telescopic magnet the collets were removed

With the valve spring compressor removed things look like this

The valve spring retainer was then removed

With the valve spring removed, you can see thevalve stem and valve stem oil seal

The valve them simply pushes out of the head.

The bare cylinder head

I cleaned all the deposits from the valves, here are a couple of before and after comparison photos

The valves stems were then measured, checked for damage/bending and llapped in with fine valve grinding paste

#537

10K+ Poster!!

Thread Starter

I've had an update from APE Raceparts, my Carrillo rods and gaskets are in stock and have been sent out to me today.

AJ Suttons sent out my new oil pump, filter, and other parts, they arrived today.

I spoke to Chris Applebee the other day regarding my crankshaft being reground, unfortunately when he checked it over, the big end journal number 3 was worn but still within the limits of a regrind and new shells, however the crankshaft was bent around this area, so it is officially scrap!

I have a spot of good news though, I took delivery of this 2005 engine yesterday

I spent this afternoon stripping it down to remove the crankshaft, the crankshaft has been measured up and bearing clearances checked with the old bearings fitted in my turbo engine, everything looks good.

That means tomorrows jobs list consists of assembling the cylinder head, checking valve clearances and ordering up some new main and big end shells and possibly some cam follower shims.

AJ Suttons sent out my new oil pump, filter, and other parts, they arrived today.

I spoke to Chris Applebee the other day regarding my crankshaft being reground, unfortunately when he checked it over, the big end journal number 3 was worn but still within the limits of a regrind and new shells, however the crankshaft was bent around this area, so it is officially scrap!

I have a spot of good news though, I took delivery of this 2005 engine yesterday

I spent this afternoon stripping it down to remove the crankshaft, the crankshaft has been measured up and bearing clearances checked with the old bearings fitted in my turbo engine, everything looks good.

That means tomorrows jobs list consists of assembling the cylinder head, checking valve clearances and ordering up some new main and big end shells and possibly some cam follower shims.

Last edited by Red16; 28-03-2012 at 09:26 PM.

#540

10K+ Poster!!

Thread Starter

#541

10K+ Poster!!

Thread Starter

The engine took a back seat at first today while I cracked on with a spot of gardening  but once finished in the garden it was straight into the garage.

but once finished in the garden it was straight into the garage.

I bought some tubing on ebay earlier in the week, it arrived today so I was able to make some progress on the oil pickup.

The inside diameter of the standard oil pickup seal is larger than the required pipework for the oil pickup. A larger piece of tube was used as a sleeve and the tube for the oil pickup now slots inside this.

Here's the modified Fireblade oil pickup tacked together

Here it is with the sump rested in position

Baffle rested roughly in position

The depth of the sump in the centre is still to be finalised, as is the oil pickup height, this is achievable because the sleeve is not welded to the pipework so the height is still able to be altered easily.

but once finished in the garden it was straight into the garage.

but once finished in the garden it was straight into the garage.I bought some tubing on ebay earlier in the week, it arrived today so I was able to make some progress on the oil pickup.

The inside diameter of the standard oil pickup seal is larger than the required pipework for the oil pickup. A larger piece of tube was used as a sleeve and the tube for the oil pickup now slots inside this.

Here's the modified Fireblade oil pickup tacked together

Here it is with the sump rested in position

Baffle rested roughly in position

The depth of the sump in the centre is still to be finalised, as is the oil pickup height, this is achievable because the sleeve is not welded to the pipework so the height is still able to be altered easily.

#543

10K+ Poster!!

Thread Starter

Cheers Gary.

I cut the holes in the baffle box and mounted it in the sump

it was then welded into position

The new con rods and gaskets are due to be delivered today and main/big end bearings hopefully in stock mid week

I cut the holes in the baffle box and mounted it in the sump

it was then welded into position

The new con rods and gaskets are due to be delivered today and main/big end bearings hopefully in stock mid week

#544

10K+ Poster!!

Thread Starter

Ding dong... that's the sound of the postman!

One set of H beam Carrillo con rods

In the con rod kit comes a bolt torque spec sheet, lubrication for the bolt threads and shoulders and some plastigauge for checking the bearing clearances.

They were expensive but they look bloody fantastic and super strong!

And just for the hell of it, here's a close up photo of two of the rods

A Cometic multi layer steel head gasket and bottom end gasket set

One set of H beam Carrillo con rods

In the con rod kit comes a bolt torque spec sheet, lubrication for the bolt threads and shoulders and some plastigauge for checking the bearing clearances.

They were expensive but they look bloody fantastic and super strong!

And just for the hell of it, here's a close up photo of two of the rods

A Cometic multi layer steel head gasket and bottom end gasket set

#546

10K+ Poster!!

Thread Starter

Still waiting on the main and big end bearings coming into stock, bugger!!

Here you can see the last of the sump baffle plates tack welded in position

When i rested the sump on the engine casing for trial fitting it had warped slightly, so a few lengths of emery cloth were stapled to the work bench and the flange face was lapped back to flat.

Here you can see the last of the sump baffle plates tack welded in position

When i rested the sump on the engine casing for trial fitting it had warped slightly, so a few lengths of emery cloth were stapled to the work bench and the flange face was lapped back to flat.

#549

10K+ Poster!!

Thread Starter

The baffle plate is now finished  here she is resting on the sump

here she is resting on the sump

and on the engine casing

With the oil pickup in position

Trial assembly

Looking into the centre of the sump, you can see the oil pickup at the top, baffle plate at the bottom and oil pressure relief valve to the right

and on the engine casing

With the oil pickup in position

Trial assembly

Looking into the centre of the sump, you can see the oil pickup at the top, baffle plate at the bottom and oil pressure relief valve to the right

#550

10K+ Poster!!

Thread Starter

This morning I checked the valve clearances.

The recommended Kawasaki clearances are,

Exhaust 0.17mm - 0.22mm (0.0067" - 0.0087")

Inlet 0.15mm - 0.24mm (0.0059" - 0.0094")

Here are some photos showing how I done it...

First off you'll need a set of feeler gauges, metric or imperial, it's entirely up to you

Set the cam lobe in this position for the clearance you wish to measure

Slide the feeler gauge blade between the cam lobe and the cam follower, making a note of the largest feeler gauge blade you can fit in the gap, this is your valve clearance measurement.

I measured the inlet clearances at 0.15-0.22mm and exhaust clearances at 0.18-22mm, they were all within tolerance so no need for adjustment.

The recommended Kawasaki clearances are,

Exhaust 0.17mm - 0.22mm (0.0067" - 0.0087")

Inlet 0.15mm - 0.24mm (0.0059" - 0.0094")

Here are some photos showing how I done it...

First off you'll need a set of feeler gauges, metric or imperial, it's entirely up to you

Set the cam lobe in this position for the clearance you wish to measure

Slide the feeler gauge blade between the cam lobe and the cam follower, making a note of the largest feeler gauge blade you can fit in the gap, this is your valve clearance measurement.

I measured the inlet clearances at 0.15-0.22mm and exhaust clearances at 0.18-22mm, they were all within tolerance so no need for adjustment.

#552

10K+ Poster!!

Thread Starter

#553

10K+ Poster!!

Thread Starter

Here's the oil pressure relief valve stripped down.

From left to right... circlip, spring retainer, spring, piston, housing

While it was stripped down i cleaned it up and rebuilt it, connected it to a compressor and tested it via an adjustable pressure regulator, it began leaking air immediately as the pressure was increased from 0psi and gradually leaked more and more until it held 70psi.

The relief valve was then stripped down again, fine valve grinding paste was applied to the piston which was then lapped in the housing, stripped and cleaned thoroughly. When retested it held pressure up to around 20psi then began to leak until it maintained 70psi of pressure. Much better than the first test.

The valve was stripped again and rebuilt with a standard M6 washer fitted between the circlip and the spring retainer, the thickness of the washer was measured at 1.55mm, this washer acts as a shim and increases the preload of the spring, thereby increasing the oil pressure setting of the relief valve. This time when tested it held pressure up to around 25-30psi then began to leak until it maintained 90psi of pressure.

This additional oil pressure should help prevent bearing failure from low oil pressure at high RPM and make up for any pressure drops through my external oil lines and oil cooler. I'll be fitting an oil pressure guage too, so I can keep an eye on things.

From left to right... circlip, spring retainer, spring, piston, housing

While it was stripped down i cleaned it up and rebuilt it, connected it to a compressor and tested it via an adjustable pressure regulator, it began leaking air immediately as the pressure was increased from 0psi and gradually leaked more and more until it held 70psi.

The relief valve was then stripped down again, fine valve grinding paste was applied to the piston which was then lapped in the housing, stripped and cleaned thoroughly. When retested it held pressure up to around 20psi then began to leak until it maintained 70psi of pressure. Much better than the first test.

The valve was stripped again and rebuilt with a standard M6 washer fitted between the circlip and the spring retainer, the thickness of the washer was measured at 1.55mm, this washer acts as a shim and increases the preload of the spring, thereby increasing the oil pressure setting of the relief valve. This time when tested it held pressure up to around 25-30psi then began to leak until it maintained 90psi of pressure.

This additional oil pressure should help prevent bearing failure from low oil pressure at high RPM and make up for any pressure drops through my external oil lines and oil cooler. I'll be fitting an oil pressure guage too, so I can keep an eye on things.

#556

10K+ Poster!!

Thread Starter

I made a base plate for the sump and tacked it in position, it has a drain hole tapped into the corner to allow the oil to bedrained from thecentral sump area. I'm not sure if i'll redo this plate and have the drain hole in the side to give a shade more ground clearance.

The new bearings finally arrived at kawasaki, part numbers for my future reference are

Big end bearing shells : Black 92139-0027 (8 off)

Main bearing shells, journals 1, 5 : Blue 92139-0029 (4 off)

Main bearing shells, journals 2, 3, 4 : Blue 92139-0032 (6 off)

A dummy build was carried out, checking big end and main bearing clearances with the plastigage supplied with the Carrillo rods, all ok.

The crankshaft was also measured for runout/bend, end float/side clearance and the conrods were also measured for side clearance, all ok.

The Carrillo rods were fitted to the pistons, here's a couple of photos of them, for no reason in particular, other than I like them

The con rod bolts are measured for stretch when fitted, this ensures they are tightened correctly. To do this you need to measure the free length of the bolts (46.30mm), check the table in the supplied booklet, the supplied M8 CARR bolts require a stretch of 0.11mm-0.15mm, so the correctly stretched length needs to be between 46.41mm and 46.45mm with no more than 43Nm (32lbft) of torque being used.

Here is a con rod bolt being measured for stretch with a micrometer

Here you can see the bolt length measures 46.43mm, which is within the recommended stretch range, this was achieved with 43Nm of torque.

The postman dropped off this -8 to 1/8" NPT adaptor to allow me to fit an oil pressure gauge sender to the engine.

The new bearings finally arrived at kawasaki, part numbers for my future reference are

Big end bearing shells : Black 92139-0027 (8 off)

Main bearing shells, journals 1, 5 : Blue 92139-0029 (4 off)

Main bearing shells, journals 2, 3, 4 : Blue 92139-0032 (6 off)

A dummy build was carried out, checking big end and main bearing clearances with the plastigage supplied with the Carrillo rods, all ok.

The crankshaft was also measured for runout/bend, end float/side clearance and the conrods were also measured for side clearance, all ok.

The Carrillo rods were fitted to the pistons, here's a couple of photos of them, for no reason in particular, other than I like them

The con rod bolts are measured for stretch when fitted, this ensures they are tightened correctly. To do this you need to measure the free length of the bolts (46.30mm), check the table in the supplied booklet, the supplied M8 CARR bolts require a stretch of 0.11mm-0.15mm, so the correctly stretched length needs to be between 46.41mm and 46.45mm with no more than 43Nm (32lbft) of torque being used.

Here is a con rod bolt being measured for stretch with a micrometer

Here you can see the bolt length measures 46.43mm, which is within the recommended stretch range, this was achieved with 43Nm of torque.

The postman dropped off this -8 to 1/8" NPT adaptor to allow me to fit an oil pressure gauge sender to the engine.

#557

Advanced PassionFord User

Join Date: May 2004

Location: Essex & Kent

Posts: 1,824

Likes: 0

Received 0 Likes

on

0 Posts

That's very sweet work the detail to everything is better than some engine builders. Let's hope it's going to take the abuse a lot better than last time