My Fiecos, Now breaking my Xr2tt. 18-7-09

#281

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

I've brought a new ignition system for the xr2tt.

Which will enable me to set the timing alot more advanced in most area's.

On the 26-03-07 i wrote this,

So outcome,

T3 turbo-

spool up is mega improved, but it dont feel very fast and boost is flicking above 15psi, so think i have a boost leak, which i will sort this week.

It dont feel very fast, but that could be either the boost leak/issue or that the turbo isn't producing the power my old T25 was.

Spent an hour on my TT tonight, 1st time i worked on the TT for a month or so, as i havent had the time to drive in, let alone work on it, so all the teething problem of the T3 hadn't been looked at.

But today i've sorted the boost issue, and now it hit's 18psi and holds it.

Which will enable me to set the timing alot more advanced in most area's.

On the 26-03-07 i wrote this,

Originally Posted by fiecos dan

So outcome,

T3 turbo-

spool up is mega improved, but it dont feel very fast and boost is flicking above 15psi, so think i have a boost leak, which i will sort this week.

It dont feel very fast, but that could be either the boost leak/issue or that the turbo isn't producing the power my old T25 was.

Spent an hour on my TT tonight, 1st time i worked on the TT for a month or so, as i havent had the time to drive in, let alone work on it, so all the teething problem of the T3 hadn't been looked at.

But today i've sorted the boost issue, and now it hit's 18psi and holds it.

#284

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Sold the turbo off the xr2tt on Friday.

i fitted a slightly modded std T3 yesterday,

but will be going stg2 or 3 next.

There will be a update coming up in next few weeks for the cossie.

but last week i checked the geometry on the fiecos.

Front,

Toe = 2 mm toe in total,

Camber = 2 degrees (just under on o/s, and just over on n/s),

Castor = 1 degree on n/s and 3/4 degree on o/s.

Rear,

Toe = 1.75 mm toe in total,

Camber = 1 degree n/s and o/s

So i want to add alot of castor on the front, and add some camber on the rear.

i fitted a slightly modded std T3 yesterday,

but will be going stg2 or 3 next.

There will be a update coming up in next few weeks for the cossie.

but last week i checked the geometry on the fiecos.

Front,

Toe = 2 mm toe in total,

Camber = 2 degrees (just under on o/s, and just over on n/s),

Castor = 1 degree on n/s and 3/4 degree on o/s.

Rear,

Toe = 1.75 mm toe in total,

Camber = 1 degree n/s and o/s

So i want to add alot of castor on the front, and add some camber on the rear.

#287

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Yeah happened on 3rd of Feb 2006, and since hadn't touched it,

as brought a house in Dec 05, and money was not there like it used to be.

But am trying to get it running for next week.

as brought a house in Dec 05, and money was not there like it used to be.

But am trying to get it running for next week.

#288

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Been working on the Xr2 to get ready for the TOTB qualifiers for PF.com and FF mag (was meant to be in cossie, but run out of time)

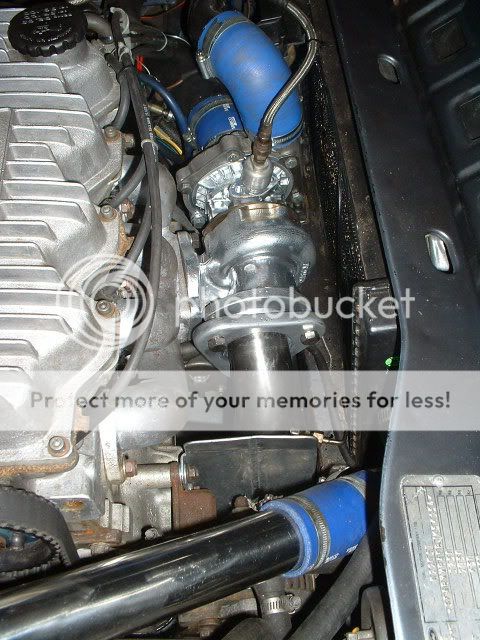

Fitted a 2wd cos turbo with cossie 0.48 bolt ex housing today.

Had to

Spin the housing, drill and retap 7 snapped bolts.

modifie actuator bracket,

modifie the down pipe.

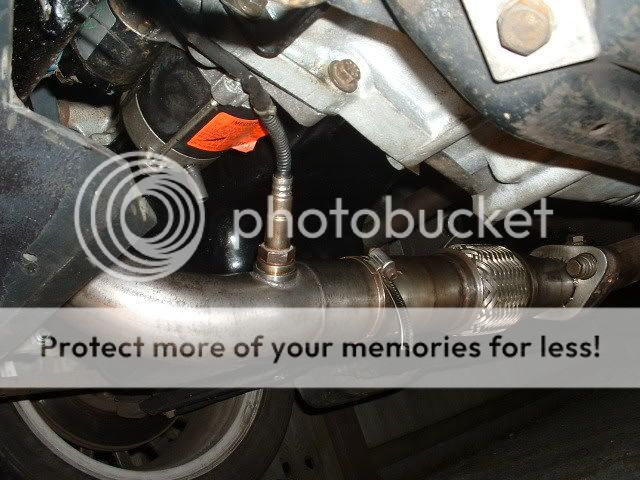

i also flowed the ex housing,

and welded a new lambda boss and EGT boss in Down pipe.

Went out in it, and it does pull well after 3500 rpm.

as i didn't have my det cans fitted, i set the boost at a safe 15 psi,

Heres boost/rpm for my last 3 turbos fitted, on on the same engine, cam, ignition and fueling.

-RPM = Hy t25=T3stg1 = 2wd T3

2000 = ------ = 05psi = 1.0psi

2500 = 07psi = 16psi = 5.5psi

3000 = 9.5psi = 15psi = 10psi

3500 = 14psi = 15psi = 14psi

4000 = 15psi = 15psi = 15psi

5000 = 15psi = 15psi = 15psi

Also the EGT's have dropped slightly as on the T25 = 1480oF, and 2wd t3 = 1400oF

I also fitted my new Kent 35 cam last night, along with new springs and anti pumps,

It now rev's to 7000 rpm.

but to compare the xr2 cam to the 35, on same 12' ign, and boost controll setting.

@ 2500 rpm = both the same @ 5 psi,

@ 3000 rpm = xr2 = 10 psi, 35 = 8 psi,

@ 3500 rpm = xr2 = 14 psi, 35 = 12 psi,

above 4000 rpm both = 15 psi.

it now rev's to 7000 rpm, but isn't pulling to great, think its due to the boost problem.(see below)

I then went to raise the boost. but i hit a wall, a leaky wastegate seems to be hold boost back.

with a -31 and pipe diconnected, this is all the boost i could get.

2500 = 5psi

3000 = 10psi

3500 = 17psi

4000 = 19psi

5500 = 21 psi.

seems like the ex housing cracks are causing this. Nothing i can do, till another housing is sourced.

But i was out early this morning testing before i went to work, and i slightly cooked the engine, (header cap slightly loose, and droping 2ltrs) and might of caused the H/G to start letting pressure into the coolant.

So i'm just going out to check it. if its good,

i need to fit a new ign system, map it, rejet the carb, fit a coolant gauge.

clean, pack. So lots to do.

_________________

Fitted a 2wd cos turbo with cossie 0.48 bolt ex housing today.

Had to

Spin the housing, drill and retap 7 snapped bolts.

modifie actuator bracket,

modifie the down pipe.

i also flowed the ex housing,

and welded a new lambda boss and EGT boss in Down pipe.

Went out in it, and it does pull well after 3500 rpm.

as i didn't have my det cans fitted, i set the boost at a safe 15 psi,

Heres boost/rpm for my last 3 turbos fitted, on on the same engine, cam, ignition and fueling.

-RPM = Hy t25=T3stg1 = 2wd T3

2000 = ------ = 05psi = 1.0psi

2500 = 07psi = 16psi = 5.5psi

3000 = 9.5psi = 15psi = 10psi

3500 = 14psi = 15psi = 14psi

4000 = 15psi = 15psi = 15psi

5000 = 15psi = 15psi = 15psi

Also the EGT's have dropped slightly as on the T25 = 1480oF, and 2wd t3 = 1400oF

I also fitted my new Kent 35 cam last night, along with new springs and anti pumps,

It now rev's to 7000 rpm.

but to compare the xr2 cam to the 35, on same 12' ign, and boost controll setting.

@ 2500 rpm = both the same @ 5 psi,

@ 3000 rpm = xr2 = 10 psi, 35 = 8 psi,

@ 3500 rpm = xr2 = 14 psi, 35 = 12 psi,

above 4000 rpm both = 15 psi.

it now rev's to 7000 rpm, but isn't pulling to great, think its due to the boost problem.(see below)

I then went to raise the boost. but i hit a wall, a leaky wastegate seems to be hold boost back.

with a -31 and pipe diconnected, this is all the boost i could get.

2500 = 5psi

3000 = 10psi

3500 = 17psi

4000 = 19psi

5500 = 21 psi.

seems like the ex housing cracks are causing this. Nothing i can do, till another housing is sourced.

But i was out early this morning testing before i went to work, and i slightly cooked the engine, (header cap slightly loose, and droping 2ltrs) and might of caused the H/G to start letting pressure into the coolant.

So i'm just going out to check it. if its good,

i need to fit a new ign system, map it, rejet the carb, fit a coolant gauge.

clean, pack. So lots to do.

_________________

#292

PassionFord Post Whore!!

Joined: Jul 2004

Posts: 4,276

Likes: 0

From: isle of wight (K.O.P 2006 mother fucker!)

got some work on the go there fella. still bummer about the cossie, but as ya say, thats life, ivehad my fair share of probelsm with cars, wont go in to it on your thread though

#293

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Update on Cossie.

Engines completely stripped.

- i stripped the head and cleaned it this morning before work, and droped it off to be skimmed, which has been done, and i collected tonight. Was 138.42mm ave, but now 138.20 ave.

- The crank is at its 2nd engine machine shop, As the 1st one, (that i usually use) wasted 3 days, and didn't bother telling me to i chased, even tho they knew it was urgent to get done in 2 days before i took it there.

Anyway, it should be 'ground' for tommorrow night, and shells will be ordered to suit, allong with new piston rings.

-The clutch had killed itself, along with the flywheel, so i had the flywheel skimmed 1.8mm, which now is 24.6mm thick. (std is 27.6+mm)

The clutch was sent off to Helix, to get refurb'd, but They said the cover and paddle wasn't worth it, so brought a new kit.

- The Dome plated front diff was sent to Dennis @ Dome, and It also has seen better days. It was meant to be fresh from a rebuild when i brought it off Some Pikee bloke called 'Pete Roberts' (named to shame),

Dennis said its had a hard life before i got it, and there was no way he's looked at it for a fair few years.

And told me its one of his 1st 10 plated cossie front diff's and is about 10-13 years old.

Anyway the good news is the 909 thick wall housing, crown and pinion are all good.

So he's gonna fit new plates, and get the cracked inner housing welded, and believes it should drive like new.

And thinks the cracked housing with the worn plates was causing the plates to twist and lock, which could be the reason my car like to swap ends under engine breaking.

- Also got a new transfer box chain comin from fords, which will cure the issue of it jumping.

Hopefully, i should have built the engine over the weekend, then i'll be waiting on the chain and diff to come back early next week before, refitment.

i have new 1000cc Rochestor injectors coming from USA, but they are f-cking me about for the time they said before i paid.

New Sealey electronic det cans comin, to aid the det checking, as the Dog box really makes it hard.

The new inter should be coming in the next week or so for a trail fit, along with new rad.

Engines completely stripped.

- i stripped the head and cleaned it this morning before work, and droped it off to be skimmed, which has been done, and i collected tonight. Was 138.42mm ave, but now 138.20 ave.

- The crank is at its 2nd engine machine shop, As the 1st one, (that i usually use) wasted 3 days, and didn't bother telling me to i chased, even tho they knew it was urgent to get done in 2 days before i took it there.

Anyway, it should be 'ground' for tommorrow night, and shells will be ordered to suit, allong with new piston rings.

-The clutch had killed itself, along with the flywheel, so i had the flywheel skimmed 1.8mm, which now is 24.6mm thick. (std is 27.6+mm)

The clutch was sent off to Helix, to get refurb'd, but They said the cover and paddle wasn't worth it, so brought a new kit.

- The Dome plated front diff was sent to Dennis @ Dome, and It also has seen better days. It was meant to be fresh from a rebuild when i brought it off Some Pikee bloke called 'Pete Roberts' (named to shame),

Dennis said its had a hard life before i got it, and there was no way he's looked at it for a fair few years.

And told me its one of his 1st 10 plated cossie front diff's and is about 10-13 years old.

Anyway the good news is the 909 thick wall housing, crown and pinion are all good.

So he's gonna fit new plates, and get the cracked inner housing welded, and believes it should drive like new.

And thinks the cracked housing with the worn plates was causing the plates to twist and lock, which could be the reason my car like to swap ends under engine breaking.

- Also got a new transfer box chain comin from fords, which will cure the issue of it jumping.

Hopefully, i should have built the engine over the weekend, then i'll be waiting on the chain and diff to come back early next week before, refitment.

i have new 1000cc Rochestor injectors coming from USA, but they are f-cking me about for the time they said before i paid.

New Sealey electronic det cans comin, to aid the det checking, as the Dog box really makes it hard.

The new inter should be coming in the next week or so for a trail fit, along with new rad.

#303

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Cheers lads,

Recieved the piston rings and Alt belt today, all i'm waiting on now is my Front diff to come back, 1000cc inj's.

Start doing the build tomorrow morning.

Recieved the piston rings and Alt belt today, all i'm waiting on now is my Front diff to come back, 1000cc inj's.

Start doing the build tomorrow morning.

#304

Originally Posted by Fiecos Dan

Cheers lads,

Recieved the piston rings and Alt belt today, all i'm waiting on now is my Front diff to come back, 1000cc inj's.

Start doing the build tomorrow morning.

Recieved the piston rings and Alt belt today, all i'm waiting on now is my Front diff to come back, 1000cc inj's.

Start doing the build tomorrow morning.

#309

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Been out in garage, and have design'd my new Front ARB adjustment setup for Castor adjustment, using modified 4wd ARB, with 2x insitu adjusters

Should only take me 3 hours at most, then another hour or so to set the castor. Which should aid the handling no end.

Should only take me 3 hours at most, then another hour or so to set the castor. Which should aid the handling no end.

#312

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

update time,

i'm weeks behind on the cossie, but the last 2 weeks, i havent been bothered about getting it running, and gonna do it in my own time now.

So due to issue's, i've missed TOTB, and Ford Fair today.

Cossie,

- Got new intercooler, Radiator and Spal fans,newer better cores, and end tank design's.

- Front diff has come back from Dome, all repaired and rebuilt

- New 1008cc Rochester injectors have arrived.

- new Cosworth billet oil pump come last week,

- Bottom end was built, BUT

- Cossie crank is still bent, so need to source another, or strip my spare std 4wd engine i have, and rap it of its crank.

Crank issue's and checks i have carried out.

i CC checked the piston and bores, and due to the cc's being out, i checked the stroke of the crank.

No 1 = 77.15mm stroke = 8.33 c/r

No 2 = 76.81mm stroke = 8.16 c/r

No 3 = 76.68mm stroke = 8.13 c/r

No 4 = 77.34mm stroke = 8.52 c/r

I then checked the stroke whilst taking up the play in the big end shells,

and pushing the piston down whilst @ BDC and pushing the rod up @ TDC.

and it added 0.04mm onto No2 stroke, and similar to No4's stroke.

i was adviced checked the flywheel for trueness, so i did this morning,

it runs +/- 0.1mm out on the diameter, and +/- 0.30 on the back and front faces.

At the point its -0.1mm on the hieght its +0.3mm on front face, and -0.30mm on back face

At the point its +0.1mm on the hieght its -0.3mm on the front, and + 0.3mm on the back face

Which shows it has bent, and even if the crank has been straightern'd on the grind, the flywheel face hasnt.

xr2tt

- Driver's recaro bottom fell thro, so i repaired that,

- New slim fan has been fitted, but isn't good enough, so needs changing again.

- fitted another 4wd t3 turbo fitted, with a better condition ex housing, which has helped lag, but still not perfect.

- Headgasket failed fully last Thursday night while boost checking,

-Headgasket has been replaced, i fitted new non strench bolts and Payden rst gasket,

the old gasket (8months old ford rst item) had failed water ways around 1 and 4 bores on both head and block faces. (due to me cooking the engine last month)

-The non strench bolts i replaced were 6-7 years old, and had be re torque'd a good 25-30 times on different specs, so thought they have had better times.

I also checked the Kent cam, and there isn't any bad wear.

Boost test on new turbo on xr2tt.

4wd T3, with cossie .48 ex housing. 1.6 turbo, 35 cam, P+F head. Reno 5 carb, and very retarded xr2TT ignition setup.

With 9psi actuator, on 10mm preload, and actuator pipe disconnected.

2000rpm = 2psi

2500rpm = 5psi ------ 5psi

3000rpm = 10psi ---- 10psi

3250rpm = 18psi

3500rpm = 24psi -----17psi

4000rpm = 22psi -----19ps

5.5-6rpm = 19psi -----21psi

boost on right is my last 2wd t3, with alot more crack's in the ex housing.

from 14-6-07, all the same spec, and test was done in same way.

Then i fitted a spare -31 actuator and done same test.

@ 2500 rpm 8psi,

@ 3000 rpm, hits 12psi then slowly builds upto to 20psi,

@ 3500 - 4000 rpm 28psi.

i'm weeks behind on the cossie, but the last 2 weeks, i havent been bothered about getting it running, and gonna do it in my own time now.

So due to issue's, i've missed TOTB, and Ford Fair today.

Cossie,

- Got new intercooler, Radiator and Spal fans,newer better cores, and end tank design's.

- Front diff has come back from Dome, all repaired and rebuilt

- New 1008cc Rochester injectors have arrived.

- new Cosworth billet oil pump come last week,

- Bottom end was built, BUT

- Cossie crank is still bent, so need to source another, or strip my spare std 4wd engine i have, and rap it of its crank.

Crank issue's and checks i have carried out.

i CC checked the piston and bores, and due to the cc's being out, i checked the stroke of the crank.

No 1 = 77.15mm stroke = 8.33 c/r

No 2 = 76.81mm stroke = 8.16 c/r

No 3 = 76.68mm stroke = 8.13 c/r

No 4 = 77.34mm stroke = 8.52 c/r

I then checked the stroke whilst taking up the play in the big end shells,

and pushing the piston down whilst @ BDC and pushing the rod up @ TDC.

and it added 0.04mm onto No2 stroke, and similar to No4's stroke.

i was adviced checked the flywheel for trueness, so i did this morning,

it runs +/- 0.1mm out on the diameter, and +/- 0.30 on the back and front faces.

At the point its -0.1mm on the hieght its +0.3mm on front face, and -0.30mm on back face

At the point its +0.1mm on the hieght its -0.3mm on the front, and + 0.3mm on the back face

Which shows it has bent, and even if the crank has been straightern'd on the grind, the flywheel face hasnt.

xr2tt

- Driver's recaro bottom fell thro, so i repaired that,

- New slim fan has been fitted, but isn't good enough, so needs changing again.

- fitted another 4wd t3 turbo fitted, with a better condition ex housing, which has helped lag, but still not perfect.

- Headgasket failed fully last Thursday night while boost checking,

-Headgasket has been replaced, i fitted new non strench bolts and Payden rst gasket,

the old gasket (8months old ford rst item) had failed water ways around 1 and 4 bores on both head and block faces. (due to me cooking the engine last month)

-The non strench bolts i replaced were 6-7 years old, and had be re torque'd a good 25-30 times on different specs, so thought they have had better times.

I also checked the Kent cam, and there isn't any bad wear.

Boost test on new turbo on xr2tt.

4wd T3, with cossie .48 ex housing. 1.6 turbo, 35 cam, P+F head. Reno 5 carb, and very retarded xr2TT ignition setup.

With 9psi actuator, on 10mm preload, and actuator pipe disconnected.

2000rpm = 2psi

2500rpm = 5psi ------ 5psi

3000rpm = 10psi ---- 10psi

3250rpm = 18psi

3500rpm = 24psi -----17psi

4000rpm = 22psi -----19ps

5.5-6rpm = 19psi -----21psi

boost on right is my last 2wd t3, with alot more crack's in the ex housing.

from 14-6-07, all the same spec, and test was done in same way.

Then i fitted a spare -31 actuator and done same test.

@ 2500 rpm 8psi,

@ 3000 rpm, hits 12psi then slowly builds upto to 20psi,

@ 3500 - 4000 rpm 28psi.

#314

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Yeah always the way mate.

not touched cossie since last update, but here's some pic's.

Cossie first.

-Rebuilt head, striped, cleaned, skimmed and lapped valves,

-Some of the parts,

-Damaged bigend and oil pump,

-Reground, (BUT STILL BENT) crank

-Modifie'd front pully for more room to move the rad back

-Hone'd block,

-Built bottom end, with new oil pump, Bent crank, rings, shells, seals, skimmed flywheel, new clutch, new balanced No4 rod.

-While i'm 'CC' checking the bottom end

- while i check the crank stoke's

- While checking the crank for bent ness

-New Rad, inter and fans.

- polished header.

-Rebuilt Dome front plated diff,

-Rebuilt rear calipers.

not touched cossie since last update, but here's some pic's.

Cossie first.

-Rebuilt head, striped, cleaned, skimmed and lapped valves,

-Some of the parts,

-Damaged bigend and oil pump,

-Reground, (BUT STILL BENT) crank

-Modifie'd front pully for more room to move the rad back

-Hone'd block,

-Built bottom end, with new oil pump, Bent crank, rings, shells, seals, skimmed flywheel, new clutch, new balanced No4 rod.

-While i'm 'CC' checking the bottom end

- while i check the crank stoke's

- While checking the crank for bent ness

-New Rad, inter and fans.

- polished header.

-Rebuilt Dome front plated diff,

-Rebuilt rear calipers.

#316

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

But i have done abit on the XR2tt,

8-07

- i've fitted the new EMS 5 ignition setup, but had issue'd with it missing on idle, but cured this last night. So will be setting it up this week.

- Gaz coilovers are fitted on the front with 300lb springs, i had to modifie the shocks, hub's and space the wheels out 10mm to fit these, but they are on.

Did have 9" springs, but couldn't lower the car past 35mm, so i fitted 8" items on now, and i've had them as low as 65mm drop with out scrub, but have put them back to my original height of -50mm.

I tried to set the front suspension up a few weeks ago, but i had a issue with the amount of castor i'm running, and play in the top shock bush,

so i've got to modifie the bottom and top cup to fit the new castor.

9-07

Fitted the new rad, and intercooler setups.

To do so,

-i've cut some of the front panel, and cross member, and seam welded the cross member.

-new rad and inter mounts have been welded in place, all the rad plumbing needed changing.

-the number plate needed repositioning, and the bumper needed quite abit of work to fit the new inter.

-I've made all new St/St boost pipe work,

-also i've made a new Alternator heat shield, and completely heat wrapped the starter motor.

To do plans

Will set front end suspension up,

fit new spax rear socks,

New rear brake lines, 1 new front, pads and fluid,

Engine oil and filter, and gearoil,

Refit a Choke on the R5 carb, as never had one fitted, and can be a Bic™ when cold weathers here,

Sort the best rad fan i can get in there,

Full set (first since i fitted the T3)

8-07

- i've fitted the new EMS 5 ignition setup, but had issue'd with it missing on idle, but cured this last night. So will be setting it up this week.

- Gaz coilovers are fitted on the front with 300lb springs, i had to modifie the shocks, hub's and space the wheels out 10mm to fit these, but they are on.

Did have 9" springs, but couldn't lower the car past 35mm, so i fitted 8" items on now, and i've had them as low as 65mm drop with out scrub, but have put them back to my original height of -50mm.

I tried to set the front suspension up a few weeks ago, but i had a issue with the amount of castor i'm running, and play in the top shock bush,

so i've got to modifie the bottom and top cup to fit the new castor.

9-07

Fitted the new rad, and intercooler setups.

To do so,

-i've cut some of the front panel, and cross member, and seam welded the cross member.

-new rad and inter mounts have been welded in place, all the rad plumbing needed changing.

-the number plate needed repositioning, and the bumper needed quite abit of work to fit the new inter.

-I've made all new St/St boost pipe work,

-also i've made a new Alternator heat shield, and completely heat wrapped the starter motor.

To do plans

Will set front end suspension up,

fit new spax rear socks,

New rear brake lines, 1 new front, pads and fluid,

Engine oil and filter, and gearoil,

Refit a Choke on the R5 carb, as never had one fitted, and can be a Bic™ when cold weathers here,

Sort the best rad fan i can get in there,

Full set (first since i fitted the T3)

#319

Thread Starter

PassionFord Post Whore!!

Joined: Oct 2003

Posts: 4,775

Likes: 0

From: S/E Kent, Thanet

Cheers Lads,

90% is done @ home, but the testing and rev'n is done up the road.

Also started to do some of it @ work, as my Boss is gr8, and its best to keep the noise down @ home.

90% is done @ home, but the testing and rev'n is done up the road.

Also started to do some of it @ work, as my Boss is gr8, and its best to keep the noise down @ home.