V8 Sierra 2WD

#41

Thread Starter

PassionFord Post Whore!!

iTrader: (2)

Joined: May 2003

Posts: 4,108

Likes: 171

From: Essex

It will be quick enough

Spec is probably going to be

Edelbrock performer rpm aluminium heads

Edelbrock performer rpm cam

Edelbrock performer air gap inlet manifold

4 barrel throttle body flowing 700CFM

High comp pistons

1 3/4 inch primary pipe exhaust manifolds

Emerald M3DK management

should be good for around 340 bhp with no lag, no boost threshold, just power from idle to 6500rpm

The only things that come in 2 litres are milk and orange juice

Supercharger is out of the question as the MT75 is going to be on borrowed time

Next months Practical Performance car has got a 5.7 litre EsCos featured allthough I doubt it's 4WD

Mark[/img]

Spec is probably going to be

Edelbrock performer rpm aluminium heads

Edelbrock performer rpm cam

Edelbrock performer air gap inlet manifold

4 barrel throttle body flowing 700CFM

High comp pistons

1 3/4 inch primary pipe exhaust manifolds

Emerald M3DK management

should be good for around 340 bhp with no lag, no boost threshold, just power from idle to 6500rpm

The only things that come in 2 litres are milk and orange juice

Supercharger is out of the question as the MT75 is going to be on borrowed time

Next months Practical Performance car has got a 5.7 litre EsCos featured allthough I doubt it's 4WD

Mark[/img]

#42

There,s a guy near me who,s done one of these and it,s f*cking awsome.

He,s been doing them for years.but the one he,s got now is bright orange and sounds the bollocks.Martin hadland knows him.

There,s some pics of it on here somewhere.

He,s been doing them for years.but the one he,s got now is bright orange and sounds the bollocks.Martin hadland knows him.

There,s some pics of it on here somewhere.

#43

Thread Starter

PassionFord Post Whore!!

iTrader: (2)

Joined: May 2003

Posts: 4,108

Likes: 171

From: Essex

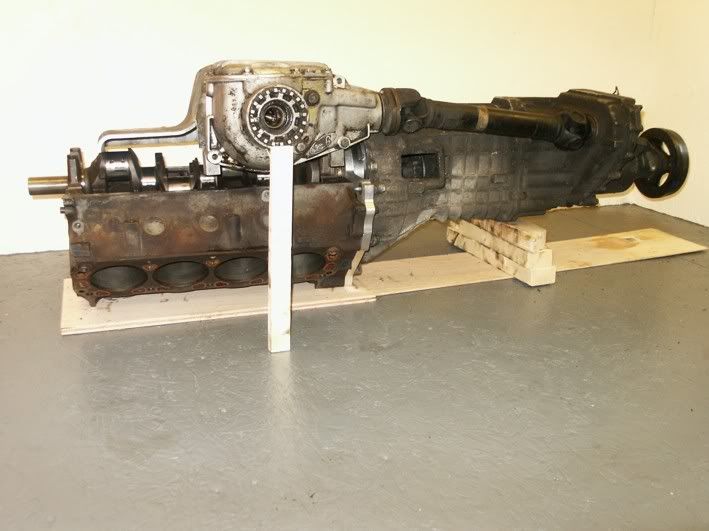

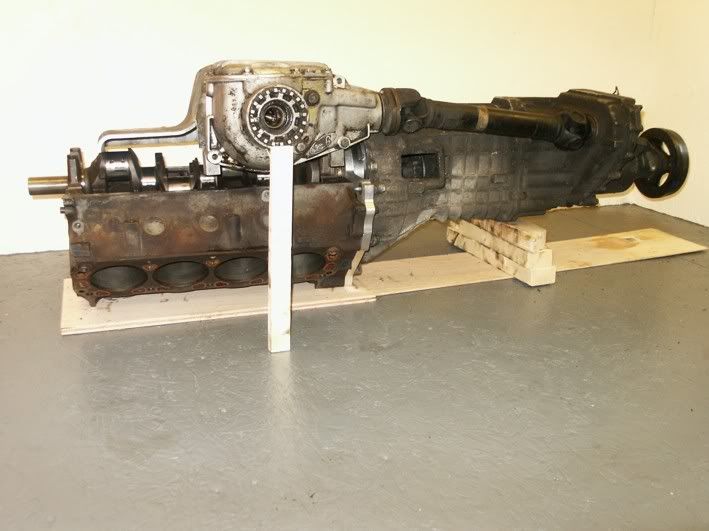

I found a bit of spare time to play down the shed and did a trial fit of engine and gearbox. Gearbox is a scrap one I bought for measurements so excuse all the oil and muck  I have a brand new MT75 waiting in the garage for when it's done.

I have a brand new MT75 waiting in the garage for when it's done.

Sump is the next job and I'll probably start by machining a base from billet aluminium and get parts of the 4x4 sump welded to it.

I also ordered a pair of Edelbrock performer rpm aluminium heads, they make them by the thousand in the US and this keeps the price sensible. £930 for the pair

Mark

Sump is the next job and I'll probably start by machining a base from billet aluminium and get parts of the 4x4 sump welded to it.

I also ordered a pair of Edelbrock performer rpm aluminium heads, they make them by the thousand in the US and this keeps the price sensible. £930 for the pair

Mark

#48

#50

Thread Starter

PassionFord Post Whore!!

iTrader: (2)

Joined: May 2003

Posts: 4,108

Likes: 171

From: Essex

You will need AutoCad 2004 onwards to open them (U torrent

http://myweb.tiscali.co.uk/rs2300/302%20to%20V6.dwg

I don't have the spare time to make any more at the moment, especially the flywheel as it was a complete bastard to machine from CSM3

http://www.crucibleservice.com/datas...TOKEN=34197332

Drawing allows more material than needed for the 50oz external balance factor to make balancing easier.

Mark

#52

this will sound great,ive watched f1 stock cars they have big v8's fookin well quick ,wot sort of power do these have,is your engine like theres???? cool project,that machineing looks spot on

#59

#65

Thread Starter

PassionFord Post Whore!!

iTrader: (2)

Joined: May 2003

Posts: 4,108

Likes: 171

From: Essex

Bit of an update.....

I ordered an aluminium sump for the V8 engine with the intent of chopping it up and welding parts of the Sierra 4x4 sump to it, unfortunately the wall section was way too thin on the new sump to be of any use. BIG THANKS to Real Steel for taking the sump back and letting me put the money towards this Edelbrock performer RPM Air Gap inlet maniflold.

Edelbrock performer RPM Air Gap inlet maniflold.

I'm still waiting on a set of injectors from the US, then I can machine the new manifold to take them.

Back to plan A with the sump and I've just had delivered to work a big lump of aluminium 23.5 x 11.5 x 3 inches, lots of measurements and drawings to be done before I cut any metal as it cost me £225

Once the design is finalised it will go on a CNC machining centre and be milled to shape, then it's plenty of trips to the local ali welder.

Mark

I ordered an aluminium sump for the V8 engine with the intent of chopping it up and welding parts of the Sierra 4x4 sump to it, unfortunately the wall section was way too thin on the new sump to be of any use. BIG THANKS to Real Steel for taking the sump back and letting me put the money towards this

I'm still waiting on a set of injectors from the US, then I can machine the new manifold to take them.

Back to plan A with the sump and I've just had delivered to work a big lump of aluminium 23.5 x 11.5 x 3 inches, lots of measurements and drawings to be done before I cut any metal as it cost me £225

Once the design is finalised it will go on a CNC machining centre and be milled to shape, then it's plenty of trips to the local ali welder.

Mark

#68

Thread Starter

PassionFord Post Whore!!

iTrader: (2)

Joined: May 2003

Posts: 4,108

Likes: 171

From: Essex

Message for rac74,

I got your PM but could not reply as your inbox is full ??

Front diff is from a Ford Sierra 2.9 XR4x4 and they are easy enough to get hold of over here, the matching rear diff tends to be a little harder to get as they have a viscous LSD and the kit car boys tend to buy them pushing the prices up.

What transfer box are you going to use on the T 56 ?

I found this a while ago and it gave me some inspiration

http://home.comcast.net/~xr4x4ti/V8_AWD_Pictures.htm

The front prop is on the other side of the engine on this setup to mine though.

regards

Mark

I got your PM but could not reply as your inbox is full ??

Front diff is from a Ford Sierra 2.9 XR4x4 and they are easy enough to get hold of over here, the matching rear diff tends to be a little harder to get as they have a viscous LSD and the kit car boys tend to buy them pushing the prices up.

What transfer box are you going to use on the T 56 ?

I found this a while ago and it gave me some inspiration

http://home.comcast.net/~xr4x4ti/V8_AWD_Pictures.htm

The front prop is on the other side of the engine on this setup to mine though.

regards

Mark

#71

pointless when can get off the shelf superhcarger kits thatd give enough power to crack the block, tho TBH on a standard 302 block that isnt that much!

deffo think the current sensible power n/a plan is wise.

#72

yup they n/a,builder i do work for bought one,goes like fook,had a play in it when he got it  ,place he got it from has a guy getting his tuned with a blower to about 900bhp,

,place he got it from has a guy getting his tuned with a blower to about 900bhp,

nice looking truck poor build quality tho

nice looking truck poor build quality tho

#74

awesome project you got going there, I love the fact that you do all the engineering work yourself, something I have allways wanted to be able to do myself so I will be keeping a lookout for progress on this. Keep the updates coming mate.

awesome project you got going there, I love the fact that you do all the engineering work yourself, something I have allways wanted to be able to do myself so I will be keeping a lookout for progress on this. Keep the updates coming mate.

#75

Thread Starter

PassionFord Post Whore!!

iTrader: (2)

Joined: May 2003

Posts: 4,108

Likes: 171

From: Essex

Bit of an update

I've been stuck on a four day week because work is not good and have spent a few days machining sump adaptor in the spare time.

Suprisingly it was too big to fit on our Mazak machining centre and was easier to do on the little bridgeport cnc.

No Cad Cam involved just done the hard way

Crap phone pic of aluminium billet

Work started on engine side of the adaptor

I'm saving the lump from the middle to make other parts from

Sump adaptor has now been turned over to machine the other side including clearance for 2.9 starter motor.

Tried on engine block

Plenty more machining and a fair bit of welding to do but it is starting to take shape

Work is still really quiet and I've got the offer of a slightly better paying more secure job that would not allow any more work on the side, I like it where I am but a 4 day week keeps me skint (real tears of indecision)

(real tears of indecision)

Mark

I've been stuck on a four day week because work is not good and have spent a few days machining sump adaptor in the spare time.

Suprisingly it was too big to fit on our Mazak machining centre and was easier to do on the little bridgeport cnc.

No Cad Cam involved just done the hard way

Crap phone pic of aluminium billet

Work started on engine side of the adaptor

I'm saving the lump from the middle to make other parts from

Sump adaptor has now been turned over to machine the other side including clearance for 2.9 starter motor.

Tried on engine block

Plenty more machining and a fair bit of welding to do but it is starting to take shape

Work is still really quiet and I've got the offer of a slightly better paying more secure job that would not allow any more work on the side, I like it where I am but a 4 day week keeps me skint

(real tears of indecision)

(real tears of indecision)Mark

I would like to do something similar using a turbo'd LS2 coupled to an OS giken box, the plans are sorted in my head already..

I would like to do something similar using a turbo'd LS2 coupled to an OS giken box, the plans are sorted in my head already..