Cosworth 205 cracked block

#44

PassionFord Post Troll

Pmsl

#45

10K+ Poster!!

iTrader: (2)

Once a riser has appeared then the core has shifted end of.

Work to save the block is just that. Not right, but the answer should be a new block. Given the option you too would choose to replace it.

#47

1st to 200 without NOS

iTrader: (2)

No, arguing because people think that a crack is ok and that its acceptable.

Once a riser has appeared then the core has shifted end of.

Work to save the block is just that. Not right, but the answer should be a new block. Given the option you too would choose to replace it.

Once a riser has appeared then the core has shifted end of.

Work to save the block is just that. Not right, but the answer should be a new block. Given the option you too would choose to replace it.

YES I would replace with new if it was a new build and a block was available BUT I'd still be happy to use the block if needed, no matter how you dress this up the block works just fine after long studding, the end!. This is based on experience.

Oh and btw I'm quite happy to take cracked 200 blocks for scrap value

Last edited by Martin-Hadland; 01-11-2017 at 10:52 AM.

#49

i believe its due to the fact that number 3 cylinder runs hotter than the others on a cossie lump. and for that reason with the bore being oversized and effectively thinner it causes the crack. if you can retard no3 a degree or so and add a splash more fuel it will keep it cooler.

nothing wrong with liners tho. some very powerful engines are liner engines. just as long as its done right. always hear about how bad the 205 block is etc etc. my opinion is that they are fine if done properly and mapped properly etc.

nothing wrong with liners tho. some very powerful engines are liner engines. just as long as its done right. always hear about how bad the 205 block is etc etc. my opinion is that they are fine if done properly and mapped properly etc.

#51

10K+ Poster!!

If we leave aside the any perceived Kudos of having a Cossie Lump would a 2.3 Duratec turbo not be worth considering as a modern alternative? Was the Guy Martin van a V6 ford lump from America, that was reliable enough at 750 bhp.

#52

PassionFord Post Troll

I would be genuinely suprised if the block would be anywhere near as strong on a duratec/zetec compared to a 200 block or rs500.

#54

10K+ Poster!!

I have always thought that there must be a fitting error with ARP kits as they would have changed the design if they failed all the time, I think I read on here that it was an issue with them bottoming out in the thread and people not checking or clearing the thread???? (something like that)

#55

I have always thought that there must be a fitting error with ARP kits as they would have changed the design if they failed all the time, I think I read on here that it was an issue with them bottoming out in the thread and people not checking or clearing the thread???? (something like that)

#56

PassionFord Post Troll

Didn't Tony measure the head after heating it upto 92 degrees and it expanded by 17thou? Stretch bolts would allow that but ARP's won't and the pressure just seems too much for the threads. Dont get me wrong previous owner fitted them to mine and when I stripped the engine the threads are ok.

Last edited by Adam-M; 02-11-2017 at 10:36 AM.

#58

Didn't Tony measure the head after heating it upto 92 degrees and it expanded by 17thou? Stretch bolts would allow that but ARP's won't and the pressure just seems too much for the threads. Dont get me wrong previous owner fitted them to mine and when I stripped the engine the threads are ok.

Which also brings another reason to the table clamping force would cause the block to split at the top too

#59

10K+ Poster!!

I will get my coat then! Lol

Surely ARP would have been made aware of this and withdrawn the product or swapped to stretch bolts? Seems odd to me.

Surely ARP would have been made aware of this and withdrawn the product or swapped to stretch bolts? Seems odd to me.

#60

300+

iTrader: (2)

Join Date: May 2004

Location: either at work or on way :)

Posts: 27,262

Received 585 Likes

on

517 Posts

Forgot engineers never do anything wrong ..i was just saying mine was fine but as explained above I must have been lucky ..the only reason I chose these in 2011 was due to the fact of boost I was going to run and not being able to long stud a 205 ..knowing this now i wish I'd stuck to standard Ford ..ive also gone down this route with my Rs turbo ..its staying standard bolts .

#61

10K+ Poster!!

Forgot engineers never do anything wrong ..i was just saying mine was fine but as explained above I must have been lucky ..the only reason I chose these in 2011 was due to the fact of boost I was going to run and not being able to long stud a 205 ..knowing this now i wish I'd stuck to standard Ford ..ive also gone down this route with my Rs turbo ..its staying standard bolts .

I think that if I ask Mark Shead to make it bullet proof he may want to liner it anyway and then I may as well not do it and just drop the money on the Ally block as the costs are too close together.?

#63

My long term plan is Smith and Jones Ally block but this thread has made me think about getting my 200 block long studded and oil squirts done seeing as I run at 469bhp with a lot of boost now, I guess the block will be worth a bit more to a buyer when I do the full build?

I think that if I ask Mark Shead to make it bullet proof he may want to liner it anyway and then I may as well not do it and just drop the money on the Ally block as the costs are too close together.?

I think that if I ask Mark Shead to make it bullet proof he may want to liner it anyway and then I may as well not do it and just drop the money on the Ally block as the costs are too close together.?

#65

Live long and prosper!!

iTrader: (1)

Forgot engineers never do anything wrong ..i was just saying mine was fine but as explained above I must have been lucky ..the only reason I chose these in 2011 was due to the fact of boost I was going to run and not being able to long stud a 205 ..knowing this now i wish I'd stuck to standard Ford ..ive also gone down this route with my Rs turbo ..its staying standard bolts .

You must have been lucky and tbh there are a lot of idiots out there who dont pay attention to the little details like cleaning threads removing any oil in the holes checking even std head bolts dont bottom out afer a head has been skimmed to death.

They just nail it together......

Mine also runs 2.2bar of boost on std head bolts with no issues on a 205 block but again its all down to who built it and do they have an accurate torque wrench.

#66

300+

iTrader: (2)

Join Date: May 2004

Location: either at work or on way :)

Posts: 27,262

Received 585 Likes

on

517 Posts

My long term plan is Smith and Jones Ally block but this thread has made me think about getting my 200 block long studded and oil squirts done seeing as I run at 469bhp with a lot of boost now, I guess the block will be worth a bit more to a buyer when I do the full build?

I think that if I ask Mark Shead to make it bullet proof he may want to liner it anyway and then I may as well not do it and just drop the money on the Ally block as the costs are too close together.?

I think that if I ask Mark Shead to make it bullet proof he may want to liner it anyway and then I may as well not do it and just drop the money on the Ally block as the costs are too close together.?

I didnt mean to come across like that and i should have read the last post by Adam.....

You must have been lucky and tbh there are a lot of idiots out there who dont pay attention to the little details like cleaning threads removing any oil in the holes checking even std head bolts dont bottom out afer a head has been skimmed to death.

They just nail it together......

Mine also runs 2.2bar of boost on std head bolts with no issues on a 205 block but again its all down to who built it and do they have an accurate torque wrench.

You must have been lucky and tbh there are a lot of idiots out there who dont pay attention to the little details like cleaning threads removing any oil in the holes checking even std head bolts dont bottom out afer a head has been skimmed to death.

They just nail it together......

Mine also runs 2.2bar of boost on std head bolts with no issues on a 205 block but again its all down to who built it and do they have an accurate torque wrench.

Last edited by Rsmat; 02-11-2017 at 01:33 PM.

#67

10K+ Poster!!

Adding up the cost of Ally block, pistons, arrow crank rods (all for 2.2 or 2.3), head work, cam, labour, mapping and all the other little bits it does get quite scary.

#68

PassionFord Post Troll

As a preventive measure I'm getting my centre six longstudded and using ARP's on the other four I don't like the idea of four stretch bolts and 6 non stretch as in my mind that would give un-even clamping pressure.

#69

PassionFord Post Whore!!

iTrader: (5)

That's quite interesting as I'm running 6 long studs and 4 stretch bolt, metal head gasket. But was getting the water system blowing slightly. Going to take the head off, etc. Half expecting a bolt loose!.

Always worried me torquing different methods on the same installation.

Martin H/Mark S

What's your views on this ?

#70

PassionFord Post Whore!!

Mark

#71

PassionFord Post Troll

Edited to add, I've seen a pic of yours and the four short ones are non stretch bolts so kind of confirms my thoughts on using standard bolts alongside longstuds.

Last edited by Adam-M; 02-11-2017 at 06:03 PM.

#72

PassionFord Post Whore!!

The old mountune ones where the same pitch and type and you tightened them diff than the stock outer studs.

All bolts stretch or yield as you could call it but all diff based on material Spec.

Mark

#73

PassionFord Post Troll

what I am saying is check the Spec of the diff length studs to make sure they are right for each other.

The old mountune ones where the same pitch and type and you tightened them diff than the stock outer studs.

All bolts stretch or yield as you could call it but all diff based on material Spec.

Mark

The old mountune ones where the same pitch and type and you tightened them diff than the stock outer studs.

All bolts stretch or yield as you could call it but all diff based on material Spec.

Mark

#75

10K+ Poster!!

iTrader: (9)

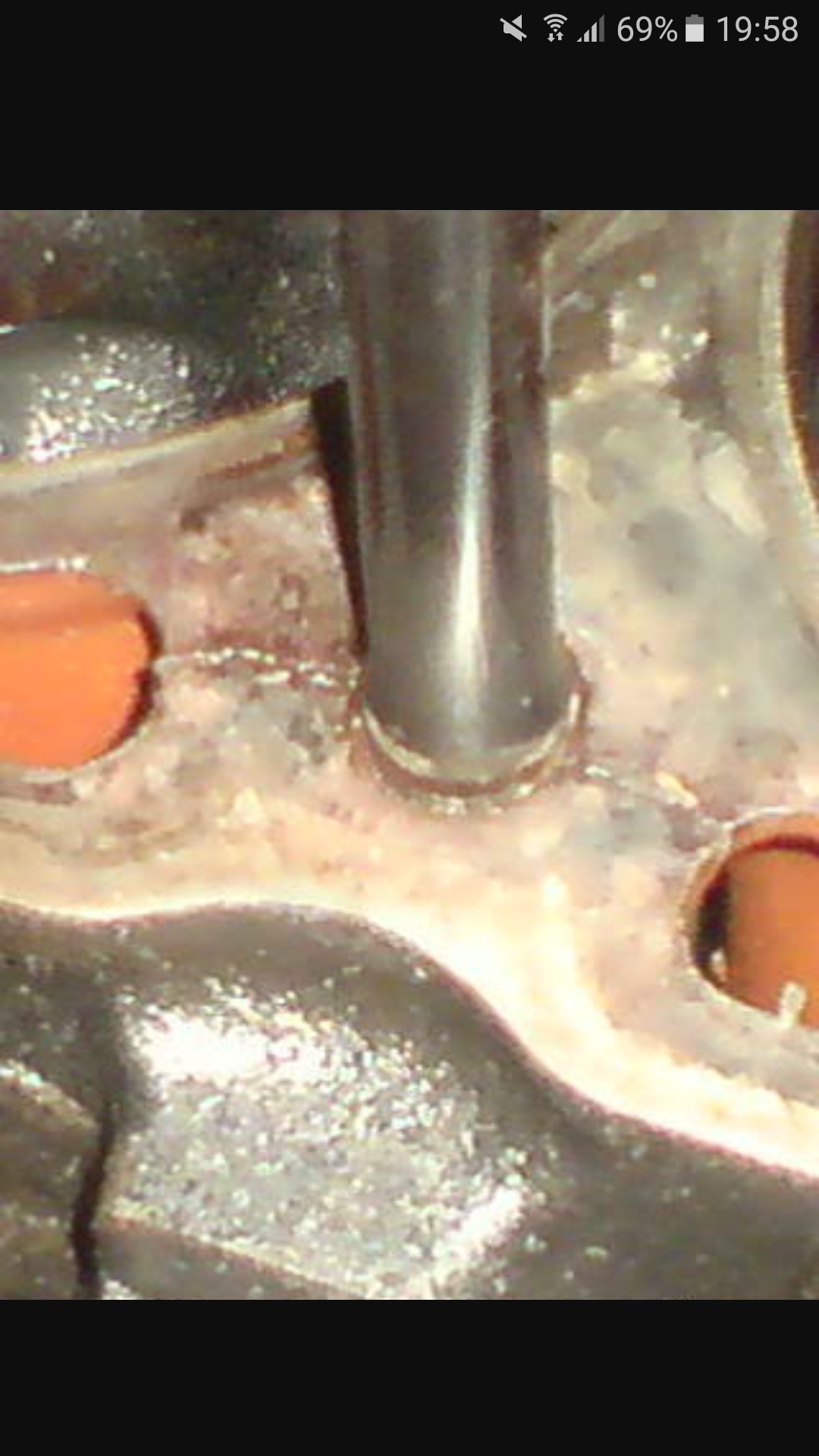

My 200 block was cracked when I bought it for £150 on standard bore

I had the cracks fully ground out then welded up and the block decked when it was long studded

I had all 10 studs done

Also I had the block drilled and tapped into cylinder number 3 for the main oil return as this is supposed to be a hot spot on the cossie block

Not sure of the truth in all this but FMS does this on all there builds for that very reason

I had the cracks fully ground out then welded up and the block decked when it was long studded

I had all 10 studs done

Also I had the block drilled and tapped into cylinder number 3 for the main oil return as this is supposed to be a hot spot on the cossie block

Not sure of the truth in all this but FMS does this on all there builds for that very reason

#76

My 200 block was cracked when I bought it for £150 on standard bore

I had the cracks fully ground out then welded up and the block decked when it was long studded

I had all 10 studs done

Also I had the block drilled and tapped into cylinder number 3 for the main oil return as this is supposed to be a hot spot on the cossie block

Not sure of the truth in all this but FMS does this on all there builds for that very reason

I had the cracks fully ground out then welded up and the block decked when it was long studded

I had all 10 studs done

Also I had the block drilled and tapped into cylinder number 3 for the main oil return as this is supposed to be a hot spot on the cossie block

Not sure of the truth in all this but FMS does this on all there builds for that very reason

mark it's a inherent problem from when the pinto first started getting tuned on carbs LOL just back then 205 blocks were £30 or £100 for a full motor . Most 200 blocks share the same issues as the 205 and if the sleeve hasn't cracked it's the back bolt hole because it's with the fact the hole wasn't cleaned properly before new bolts or because the threads are right at the top of the block and the clamping cracks them. This is why 200s are preferred above 400 bhp as the thicker waist allows long stuffing so you are clamping from the bottom of the block so less stress on the face of the block so better clamping

#78

I'd say if your doing a build above 400 ish it's a no brainer as it is part of gaining reliability and why not as if you going for power and spending good monry why skip the important bits . I remember Karl Norris doing a write up on 500 bhp engines and said standard bolts are fine as long as you change them every 3 to 4k now I don't like that idea as steady hs already mentioned ever bolt is different and what if the clamp isn't as tight as previous and you are still clamping at the top of the block

The following 2 users liked this post by Jay,:

Fudgey (06-11-2017),

james kiely (05-11-2017)

#79

Regular Contributor

Join Date: Nov 2007

Location: it's not where you are, it's where you've been and where you hope to be

Posts: 267

Likes: 0

Received 16 Likes

on

16 Posts

when 6 long studs are fitted the material of the long studs (steel) will also expand at half that of the head but since they are twice as long as the head is thick, the situation becomes about equal. i don't know if arp considered this or just jumped on bandwagon of supplying bolts as there were lots of folk rebuilding cosworth engines but if their studs are just 'high quality steel' without any concessions to the above point then that's maybe why they seem to pull the threads out

The following users liked this post:

james kiely (05-11-2017)

#80

PassionFord Post Troll

the head is aluminium and the bolts are steel. aluminium expands about twice the rate of the steel bolts and as the engine heats up, the head will expand 100% more than the studs want to. the very reason that the std studs are 'stretch bolts' is to accommodate this situation as they have a greater stretch /force and are more elastic than normal bolts so they will return to the original length when cold.

when 6 long studs are fitted the material of the long studs (steel) will also expand at half that of the head but since they are twice as long as the head is thick, the situation becomes about equal. i don't know if arp considered this or just jumped on bandwagon of supplying bolts as there were lots of folk rebuilding cosworth engines but if their studs are just 'high quality steel' without any concessions to the above point then that's maybe why they seem to pull the threads out

when 6 long studs are fitted the material of the long studs (steel) will also expand at half that of the head but since they are twice as long as the head is thick, the situation becomes about equal. i don't know if arp considered this or just jumped on bandwagon of supplying bolts as there were lots of folk rebuilding cosworth engines but if their studs are just 'high quality steel' without any concessions to the above point then that's maybe why they seem to pull the threads out