T4 divided flange with holes slightly out? What to do?

#1

DEYTUKURJERBS

Thread Starter

Just tried offering up the Holset turbo and my manifold and the bolt holes didnt quite line up.

So, presuming the cheap ass stainless manifold was out, I checked it versus the usual T4 flange dimensions...

The manifold is spot on, perfect, the turbo is the one with the bolts in the wrong place! But its been dileberatly done like this it seems

Basically the one direction the hole to hole is spot on, 2.75in, but the

other direction its further apart, 3.5in rather than 3.25!

As far as I can see it I can just about, if im REALLY lucky, elongate the holes on the turbine housing until it fits, which may or may not work, and if it doesnt ive fucked it totally

The other option is elongate the holes on the manifold flange slightly, but there is only 5mm either side to cut, and id need to cut 6mm, so it will be near enough open ended then, and surely that will make the turbo able to move around and blow?

Anyone got any ideas/opinions, etc?

So, presuming the cheap ass stainless manifold was out, I checked it versus the usual T4 flange dimensions...

The manifold is spot on, perfect, the turbo is the one with the bolts in the wrong place! But its been dileberatly done like this it seems

Basically the one direction the hole to hole is spot on, 2.75in, but the

other direction its further apart, 3.5in rather than 3.25!

As far as I can see it I can just about, if im REALLY lucky, elongate the holes on the turbine housing until it fits, which may or may not work, and if it doesnt ive fucked it totally

The other option is elongate the holes on the manifold flange slightly, but there is only 5mm either side to cut, and id need to cut 6mm, so it will be near enough open ended then, and surely that will make the turbo able to move around and blow?

Anyone got any ideas/opinions, etc?

#5

DEYTUKURJERBS

Thread Starter

Well TBH, if my thinking is right, if i make the holes on the turbo bigger, the turbo still wont be able to move, as the holes are on the inside, so no need to weld em up?

Not 100% if there enough meat on the inside to do that tho, its fucking close to the actual meat of the housing.

Not 100% if there enough meat on the inside to do that tho, its fucking close to the actual meat of the housing.

#7

DEYTUKURJERBS

Thread Starter

There you go

They identical on the horisontal axis, but the turbo has .25in wider than standard on the vertical axis...

All other things, like port sizes, are identical.

They identical on the horisontal axis, but the turbo has .25in wider than standard on the vertical axis...

All other things, like port sizes, are identical.

Last edited by Stavros; 02-07-2008 at 09:30 PM.

Trending Topics

#10

10K+ Poster!!

iTrader: (1)

Join Date: May 2003

Location: Lancashire

Posts: 12,748

Likes: 0

Received 0 Likes

on

0 Posts

How about making a template of the turbo flange, get a new flange laser cut and get it swapped over on the manifold. Permanent solution.

Last edited by DazC; 02-07-2008 at 09:51 PM.

#12

10K+ Poster!!

iTrader: (1)

Join Date: May 2003

Location: Lancashire

Posts: 12,748

Likes: 0

Received 0 Likes

on

0 Posts

Got more engineering companies round here than I can crimp logs off in a year with IBS so I find getting things made relatively easy. Wasn't sure how easy it is down your way though.

#13

Advanced PassionFord User

Join Date: May 2003

Location: Beds

Posts: 2,376

Likes: 0

Received 0 Likes

on

0 Posts

Personaly if was me, and was looking for the cheapest way, I'd slot the holes in the turbo, and if really worried OR it PROVES a problem with the turbo moving, just weld plates on to your manifold holding it central

THE best way is take it to a machinist who could elongate your holes and do it acurately and still leave meat on your turbo, not much but enough to hold it central

.

.Any ideas WHY it would have been made "special" like that

Steve

#17

DEYTUKURJERBS

Thread Starter

Fudgey- I can get it welded anywhere im sure, but not sure who can cut me a flange to my drawings, or can that place do that?

As im not sure if there will be room for the nuts, I dont wanna risk modding the housing.

As im not sure if there will be room for the nuts, I dont wanna risk modding the housing.

#18

Advanced PassionFord User

Join Date: May 2003

Location: Beds

Posts: 2,376

Likes: 0

Received 0 Likes

on

0 Posts

If you taking it somewhere good enough to make a flange and weld it on, would be damn sure they good enough to elongate the holes, gotta be cheaper to, and as i said before keeps the manifold all correct as it should be

Steve

#21

Advanced PassionFord User

Join Date: May 2003

Location: Beds

Posts: 2,376

Likes: 0

Received 0 Likes

on

0 Posts

OH and forgot cutting the old one off and welding the new one on !

OH and forgot cutting the old one off and welding the new one on !Steve

Last edited by The Rapid 1; 02-07-2008 at 10:05 PM.

#23

Advanced PassionFord User

Join Date: May 2003

Location: Beds

Posts: 2,376

Likes: 0

Received 0 Likes

on

0 Posts

#25

DEYTUKURJERBS

Thread Starter

How cheap is cheap? I know nothing about all this malarky, lazer cutting sounds like something expensive from Starwars, milling dont, but I know fuck all

Deffo need to get a new flange made, not worth the risk modding the turbo.

Deffo need to get a new flange made, not worth the risk modding the turbo.

#26

10K+ Poster!!

iTrader: (1)

Join Date: May 2003

Location: Lancashire

Posts: 12,748

Likes: 0

Received 0 Likes

on

0 Posts

Well I went into my local cutters a couple of years ago and asked them to cut me a couple of wheel spacers in 2mm ally. When I asked how much they started rambling on about minimum charges which then came out as £20.

That flange is only as complex as a wheel spacer so can't see it being any more than £40 bearing in mind cost of materials going up since I had them cut.

A lazer cutter will cut that in about 15 seconds from setting the machine off.

That flange is only as complex as a wheel spacer so can't see it being any more than £40 bearing in mind cost of materials going up since I had them cut.

A lazer cutter will cut that in about 15 seconds from setting the machine off.

#27

DEYTUKURJERBS

Thread Starter

And what do i need to do? Go there with a drawing with measurments on it?

I presume it dont need to be 3D, just tell them how thick it needs to be.

I presume it dont need to be 3D, just tell them how thick it needs to be.

#28

10K+ Poster!!

iTrader: (1)

Join Date: May 2003

Location: Lancashire

Posts: 12,748

Likes: 0

Received 0 Likes

on

0 Posts

Pretty much yeah. Just make a flat drawing of the turbo flange with all the measurements, or when I got my spacers made, I took them a spacer and said copy that in 2mm ally. You could just leave them the turbo and point the bit out you want copying in 8/10mm stainless or how ever thick it is.

It'll take them longer to write the program to cut it than actually cut the thing.

It'll take them longer to write the program to cut it than actually cut the thing.

#29

*** Sierra RS Custard ***

iTrader: (3)

Personally my advice would be:

Drill and tap the manifold to take a helicoil

Studs into manifold

Slot the turbo rallyslag stylee

Nuts the other side (assuming there is enough clearance)

If there isnt enough clearance to do that, then do the opposite and slot the manifold, the nuts might only 3/4 overlap it but fuck it not like they are going to pull through anyway so who cares?

Last edited by Chip; 02-07-2008 at 11:31 PM.

#30

DEYTUKURJERBS

Thread Starter

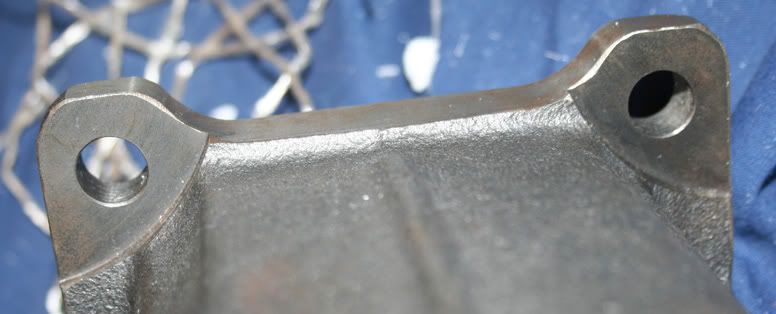

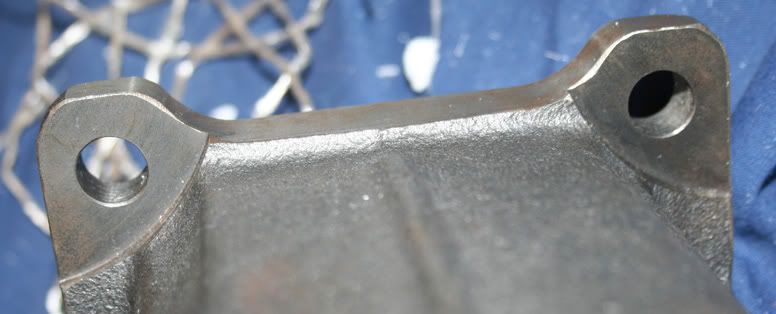

Aah poo, a stainless manifold to normal turbine needs a gasket doesnt it? Due to differing expansion rates?

Anyhow, when I thought that I realised I had a T4 flange gasket, and also realised if I made a custom flange id also need a custom gasket

BUT I reckon, aside from the possible issue of getting a bolt on the end with 2 of the holes once ive elongated it, modding the housing is the best option.

Heres some pics which roughly demonstrate what I mean, though not ideal as I was struggling to keep the gasket steady while taking a pic! In reality the gasket holes sit perfect with the manifold...

Manifold

Turbo

Tons of room

Worrying lack of room

Anyhow, when I thought that I realised I had a T4 flange gasket, and also realised if I made a custom flange id also need a custom gasket

BUT I reckon, aside from the possible issue of getting a bolt on the end with 2 of the holes once ive elongated it, modding the housing is the best option.

Heres some pics which roughly demonstrate what I mean, though not ideal as I was struggling to keep the gasket steady while taking a pic! In reality the gasket holes sit perfect with the manifold...

Manifold

Turbo

Tons of room

Worrying lack of room

#32

DEYTUKURJERBS

Thread Starter

How do I stud the 2 holes on the turbo that are just normal holes?

2 are stud already tho, 2 are just much bigger holes.

EDIT- I looked it up, a helicoil! But the kits dont look cheap, esp as only need to do it once. Can I take it to someone to do it??? I know nowt about this sorta thing.

2 are stud already tho, 2 are just much bigger holes.

EDIT- I looked it up, a helicoil! But the kits dont look cheap, esp as only need to do it once. Can I take it to someone to do it??? I know nowt about this sorta thing.

Last edited by Stavros; 02-07-2008 at 11:19 PM.

#33

*** Sierra RS Custard ***

iTrader: (3)

How do I stud the 2 holes on the turbo that are just normal holes?

2 are stud already tho, 2 are just much bigger holes.

EDIT- I looked it up, a helicoil! But the kits dont look cheap, esp as only need to do it once. Can I take it to someone to do it??? I know nowt about this sorta thing.

2 are stud already tho, 2 are just much bigger holes.

EDIT- I looked it up, a helicoil! But the kits dont look cheap, esp as only need to do it once. Can I take it to someone to do it??? I know nowt about this sorta thing.

or you can buy just the helicoil on its own if you can borrow a tap the right size

#35

DEYTUKURJERBS

Thread Starter

Cheers mate, the more I look at it the more thats the best idea. Nice one, ill get it done ASAP

EDIT- Yeah, TBH there plenty of room to do that, spose that'd work ok.

Only problem is, wont this give the turbo the ability to move around? Or will doing it up reeeal tight just be ok???

EDIT- Yeah, TBH there plenty of room to do that, spose that'd work ok.

Only problem is, wont this give the turbo the ability to move around? Or will doing it up reeeal tight just be ok???

Last edited by Stavros; 02-07-2008 at 11:29 PM.

#36

*** Sierra RS Custard ***

iTrader: (3)

At least if it goes horribly wrong the worst that can happen is you get a new flange cut for the manifold thats 3.5" apart and get it tigged on, pain in the arse but beats the hell out of scrapping the turbo housing potentially.

Ive just thought of one other TRUE bodge, use M6 bolts, they will fit through where the holes half line up, it would at least do for a few test drives, lol

Ive just thought of one other TRUE bodge, use M6 bolts, they will fit through where the holes half line up, it would at least do for a few test drives, lol

#37

DEYTUKURJERBS

Thread Starter

I want it to stay where it is.

So even tho the turbo could move if was loose enough due to elongating the manifold holes, if the bolts are done up ok it should sit tight and seal ok?

So even tho the turbo could move if was loose enough due to elongating the manifold holes, if the bolts are done up ok it should sit tight and seal ok?

#39

Testing the future

i would go with 4 x M6 bolts if you can get them through. one M6 bolt will hold the weight of an old mini, so 4 to hold on a turbo is plenty. virtually everything in this world (except racing machines) is made twice as strong as it needs to be.

you obviously need all metal locknuts though, but if they do work loose you haven't lost anything

you obviously need all metal locknuts though, but if they do work loose you haven't lost anything