Vauxhall C16XE engine toque settings?

#1

Hopfully start putting a C16xe together this weekend for the track Nova, just been having a quick look on the net for the toque settings for the engine internals and carnt find much, only the LET and 20XE settings.

Anyone help?

Cheers

Anyone help?

Cheers

#5

1.4L - 1.6L 16V TORQUE WRENCH SETTINGS

Specifications subject to change without prior notice - issue date 25-01-07

MAIN CAP BOLTS (Standard & SBD Cap Head Type)

GRAPHITE GREASE UNDER HEAD,OIL THREADS

STAGE 1---37 LB/FT

STAGE 2---45 degree

STAGE 3---15 degree

BIG END BOLTS

Standard Type GM Rod Bolts

STAGE 1---18 LB/FT (GRAPHITE GREASE UNDER HEAD,OIL THREADS)

STAGE 2---30 degree

Heavy Duty Rods Bolts for Standard Rods -See separate instruction sheets

RB2K, RB2K-F, RB4, RB5, RB6

NOTE: - When assembling the bolts, as of 2002, the manufacturers recommend only using ARP assembly lubricant as supplied, under the heads and on the threads and torque up to. These are lower torque settings than would have been used with normal oil. We cannot be held responsible for rod bolt stretch when an uncalibrated torque wrench has been used.

OIL PUMP BOLTS

4 LB/FT(242 LOCTITE)

CRANK BOLT

GRAPHITE GREASE UNDER HEAD & WASHER, OIL THREAD

STAGE 1---70LB/FT

STAGE 2---30 degree

STAGE 3---15 degree

CAM CAPS

6 LB/FT

CAM PULLEY BOLT

48 LB/FT(242 LOCTITE)

CAM VERNIER PULLEY BOLTS

14LB/FT

IDLER PULLEY BOLTS

18 LB/FT(242 LOCTITE)

CAM BELT AUTO TENSIONER BOLT

15 LB/FT

SUMP BOLTS

242 LOCTITE

STEEL SUMP---4 LB/FT

ALLOY SUMP--6 LB/FT

DRY SUMP-----10 NM

STANDARD FLYWHEEL BOLTS

242 LOCTITE

STAGE 1---26 LB/FT

STAGE 2---30 degree

STAGE 3---15 degree

ARP FLYWHEEL BOLTS

35 LB/FT with ARP Lube

45 LB/FT with engine oil

CYLINDER HEAD BOLTS for Standard gaskets

GRAPHITE GREASE UNDER HEADS & WASHERS, OIL THREADS

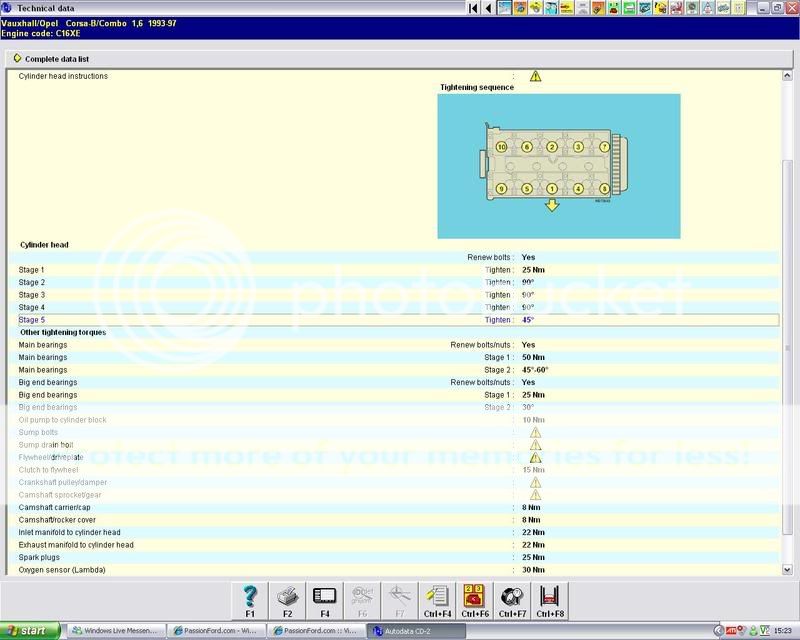

SEE BELOW FOR TIGHTNING SEQUENCE

STAGE 1---18 LB/FT 25NM

STAGE 2---90 degree

STAGE 3---90 degree

STAGE 4---90 degree

STAGE 5---45 degree

HEAD STUDS (BLT-H3-STUD-KIT) for Cometic gaskets only

Due to the difference in quality of both Genuine and pattern standard head bolts, these are not suitable, therefore we can only recommend the use of the ARP HEAD STUD KIT when using a Cometic gasket. The torque settings and instructions below must be followed:

IF COOLING MODS HAVE BEEN DONE THEN THE COMETIC GASKET MUST BE DIMPLED

ALWAYS wash the fasteners with cleaning solvent prior to installation. They come coated with a 'protective' coating, this is NOT a lubricant.

METHOD

Supplied ARP lubricant must be used on all threads and underneath face of nut.

BEFORE CYLINDER HEAD IS INSTALLED: -

1. Ensure threads in block & on stud are completely clean

2. Apply lubricant to stud threads & screw stud into block finger tight only.

STAGE 1---25 LB/FT

STAGE 2---Back off ½ turn

STAGE 3---25 LB/FT

STAGE 4---60 LB/FT

STAGE 5---Back off ¼ turn

STAGE 6---60 LB/FT

ONCE CYLINDER HEAD IS INSTALLED, FIT NUTS & WASHERS - THIS MUST ALWAYS BE IN THE SEQUENCE SHOWN BELOW:

1. Pull up the nuts & washers to 25lb/ft torque & then back off ½ turn.

2. Repeat this twice and on the third time torque to 60lb/ft.

3. Back off ¼ turn

4. Finally torque up the nuts & washers to 60lb/ft.

Specifications subject to change without prior notice - issue date 25-01-07

MAIN CAP BOLTS (Standard & SBD Cap Head Type)

GRAPHITE GREASE UNDER HEAD,OIL THREADS

STAGE 1---37 LB/FT

STAGE 2---45 degree

STAGE 3---15 degree

BIG END BOLTS

Standard Type GM Rod Bolts

STAGE 1---18 LB/FT (GRAPHITE GREASE UNDER HEAD,OIL THREADS)

STAGE 2---30 degree

Heavy Duty Rods Bolts for Standard Rods -See separate instruction sheets

RB2K, RB2K-F, RB4, RB5, RB6

NOTE: - When assembling the bolts, as of 2002, the manufacturers recommend only using ARP assembly lubricant as supplied, under the heads and on the threads and torque up to. These are lower torque settings than would have been used with normal oil. We cannot be held responsible for rod bolt stretch when an uncalibrated torque wrench has been used.

OIL PUMP BOLTS

4 LB/FT(242 LOCTITE)

CRANK BOLT

GRAPHITE GREASE UNDER HEAD & WASHER, OIL THREAD

STAGE 1---70LB/FT

STAGE 2---30 degree

STAGE 3---15 degree

CAM CAPS

6 LB/FT

CAM PULLEY BOLT

48 LB/FT(242 LOCTITE)

CAM VERNIER PULLEY BOLTS

14LB/FT

IDLER PULLEY BOLTS

18 LB/FT(242 LOCTITE)

CAM BELT AUTO TENSIONER BOLT

15 LB/FT

SUMP BOLTS

242 LOCTITE

STEEL SUMP---4 LB/FT

ALLOY SUMP--6 LB/FT

DRY SUMP-----10 NM

STANDARD FLYWHEEL BOLTS

242 LOCTITE

STAGE 1---26 LB/FT

STAGE 2---30 degree

STAGE 3---15 degree

ARP FLYWHEEL BOLTS

35 LB/FT with ARP Lube

45 LB/FT with engine oil

CYLINDER HEAD BOLTS for Standard gaskets

GRAPHITE GREASE UNDER HEADS & WASHERS, OIL THREADS

SEE BELOW FOR TIGHTNING SEQUENCE

STAGE 1---18 LB/FT 25NM

STAGE 2---90 degree

STAGE 3---90 degree

STAGE 4---90 degree

STAGE 5---45 degree

HEAD STUDS (BLT-H3-STUD-KIT) for Cometic gaskets only

Due to the difference in quality of both Genuine and pattern standard head bolts, these are not suitable, therefore we can only recommend the use of the ARP HEAD STUD KIT when using a Cometic gasket. The torque settings and instructions below must be followed:

IF COOLING MODS HAVE BEEN DONE THEN THE COMETIC GASKET MUST BE DIMPLED

ALWAYS wash the fasteners with cleaning solvent prior to installation. They come coated with a 'protective' coating, this is NOT a lubricant.

METHOD

Supplied ARP lubricant must be used on all threads and underneath face of nut.

BEFORE CYLINDER HEAD IS INSTALLED: -

1. Ensure threads in block & on stud are completely clean

2. Apply lubricant to stud threads & screw stud into block finger tight only.

STAGE 1---25 LB/FT

STAGE 2---Back off ½ turn

STAGE 3---25 LB/FT

STAGE 4---60 LB/FT

STAGE 5---Back off ¼ turn

STAGE 6---60 LB/FT

ONCE CYLINDER HEAD IS INSTALLED, FIT NUTS & WASHERS - THIS MUST ALWAYS BE IN THE SEQUENCE SHOWN BELOW:

1. Pull up the nuts & washers to 25lb/ft torque & then back off ½ turn.

2. Repeat this twice and on the third time torque to 60lb/ft.

3. Back off ¼ turn

4. Finally torque up the nuts & washers to 60lb/ft.

Trending Topics

#8

Originally Posted by Rossco

Proper bo

Cheers mate

Whens your Nova back at Woodbridge?

Cheers mate

Whens your Nova back at Woodbridge?

until its quieter it won't be back lol, still waiting to get the proper engine back in it as its had a stock xe on tb's in it since before Chistmas.

Thread

Thread Starter

Forum

Replies

Last Post

track.focus'd

Restorations, Rebuilds & Projects.

26

12-08-2015 05:53 PM

Zoggon

Ford Sierra/Sapphire/RS500 Cosworth

5

10-08-2015 10:39 AM