"Wide" bearing for gear linkage?

#1

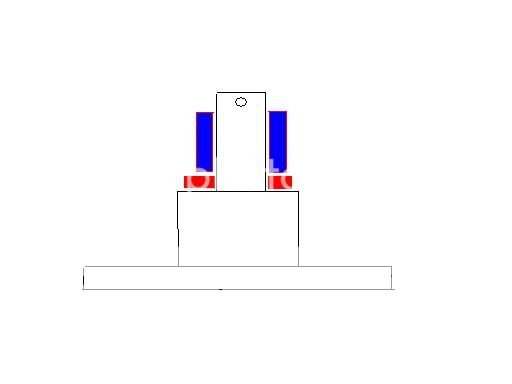

I need to make a gear linkage that involves a see-saw in the middle of it.

Kind of like this:

I want to use a bearing with a lot less give in it than a plastic bush though to make the change more positive.

Obviously it would be possible to make something with a bearing at either end (like the way wheel bearings work) but I just wondered if anyone know of a source of wide (30mm or wider) small diameter bearings (8-10mm hole in the middle and around 20-30mm diamter for the outside) that I could use that are off the shelf though?

Kind of like this:

I want to use a bearing with a lot less give in it than a plastic bush though to make the change more positive.

Obviously it would be possible to make something with a bearing at either end (like the way wheel bearings work) but I just wondered if anyone know of a source of wide (30mm or wider) small diameter bearings (8-10mm hole in the middle and around 20-30mm diamter for the outside) that I could use that are off the shelf though?

#2

PassionFord Post Whore!!

these would be sufficient, http://www.bearingboys.co.uk/ourshop...25-ROLLER.html

2 of these with a 15mm spacer would do the job if the linkage has space for them.

2 of these with a 15mm spacer would do the job if the linkage has space for them.

#3

Yeah thats what im planning on doing if I cant find a bearing thats already wide enough

But was wondering if there was anything suitable that was already complete with the spacer in the middle and preferabley some sort of outer casing I should weld the arms onto.

(ie just cut the bearings out the linkage above and weld the new one in)

But was wondering if there was anything suitable that was already complete with the spacer in the middle and preferabley some sort of outer casing I should weld the arms onto.

(ie just cut the bearings out the linkage above and weld the new one in)

#4

PassionFord Post Troll

If the lever has to be located you could probably find a needle roller bearing in the dimensions you mention above. You want to make sure all the forces are in line

If the points that the cable pull from are fixed, or if there is going to be any sidways force you are probablt best going for a sphecical bearing.

If the points that the cable pull from are fixed, or if there is going to be any sidways force you are probablt best going for a sphecical bearing.

#6

PassionFord Post Whore!!

i'd get a shaft made up to fit one of these, http://www.bearingboys.co.uk/ourshop...DRAWN-CUP.html

the shaft would have to be 0.03 under size for the bearing to work well.

the shaft would have to be 0.03 under size for the bearing to work well.

#7

Originally Posted by wirralphil

i'd get a shaft made up to fit one of these, http://www.bearingboys.co.uk/ourshop...DRAWN-CUP.html

the shaft would have to be 0.03 under size for the bearing to work well.

the shaft would have to be 0.03 under size for the bearing to work well.

That doesnt look too bad an option, would welding to the outer case damage the bearing though, as obviously thats a lot of heat and normally the needles are in nylon arent they?

Trending Topics

#8

PassionFord Post Troll

If you weld to a bearing case the heat will fuck it up.

Best way is to turn up a bearing housing with interferance fit and then press bearing in. Or use the oven/freezer method if you are confident of your measurements.

Ideally you need to weld the bits onto the housing and finish to final size.

Best way is to turn up a bearing housing with interferance fit and then press bearing in. Or use the oven/freezer method if you are confident of your measurements.

Ideally you need to weld the bits onto the housing and finish to final size.

#9

Originally Posted by Garage19

If you weld to a bearing case the heat will fuck it up.

Best way is to turn up a bearing housing with interferance fit and then press bearing in. Or use the oven/freezer method if you are confident of your measurements.

Ideally you need to weld the bits onto the housing and finish to final size.

Best way is to turn up a bearing housing with interferance fit and then press bearing in. Or use the oven/freezer method if you are confident of your measurements.

Ideally you need to weld the bits onto the housing and finish to final size.

This is why I was hoping to find some existing item that already had all that done, so I could just push the bearings out, weld and chop it about, then pop them back in.

#10

Resident Wrestling Legend

iTrader: (3)

looks like there will be the need for lateral movement as well as side to side and up and down

i'm assuming there will be no other way to make the ball joints at the ends twist to change from one plane other than doing it this way?

if it's just normal rotation then the needle rollers would suffice but i'd rather bet on the normla ball race bearings just to be on the safe side

i'm assuming there will be no other way to make the ball joints at the ends twist to change from one plane other than doing it this way?

if it's just normal rotation then the needle rollers would suffice but i'd rather bet on the normla ball race bearings just to be on the safe side

#12

PassionFord Post Whore!!

no heat near the bearing as it will just fail.

measure the linkage bore with a vernier more than likley it will be a nominal size like 28, 30mm etc a trasition fit would be best tho so you don't crack the linkage. loctite has a good few bearing glues for the job.

measure the linkage bore with a vernier more than likley it will be a nominal size like 28, 30mm etc a trasition fit would be best tho so you don't crack the linkage. loctite has a good few bearing glues for the job.

#14

Resident Wrestling Legend

iTrader: (3)

as long as you can find a shaft to mount the wide bearing t, they come up to 22mm from that list (or bigger for the 60mm shaft) you are only limited by the amount of space you have

it's very easy to over engineer this with huge amounts of metal to stop the flex

the other solution would be to get some sort of threaded sleve made up to go over the needle bearing and not only use that to screw into the casing, but also to support the side with some big burly nuts and washer types

it's very easy to over engineer this with huge amounts of metal to stop the flex

the other solution would be to get some sort of threaded sleve made up to go over the needle bearing and not only use that to screw into the casing, but also to support the side with some big burly nuts and washer types

#16

Testing the future

i wouldn't worry about welding to the bearing personally - as long as the weld does not penetrate right through to the running surface

i would disassemble the bearing first and remove grease though, and then repack after

it's not like the bearing is constantly rotating, so can't see it doing any harm

i would disassemble the bearing first and remove grease though, and then repack after

it's not like the bearing is constantly rotating, so can't see it doing any harm

Thread

Thread Starter

Forum

Replies

Last Post

nicodinho

Ford Non RS / XR / ST parts for sale.

6

07-10-2015 12:56 PM