Ford F150 (Project Gas Guzzler)

#44

Thread Starter

Advanced PassionFord User

iTrader: (2)

Joined: Apr 2009

Posts: 2,229

Likes: 0

From: BC, Canada

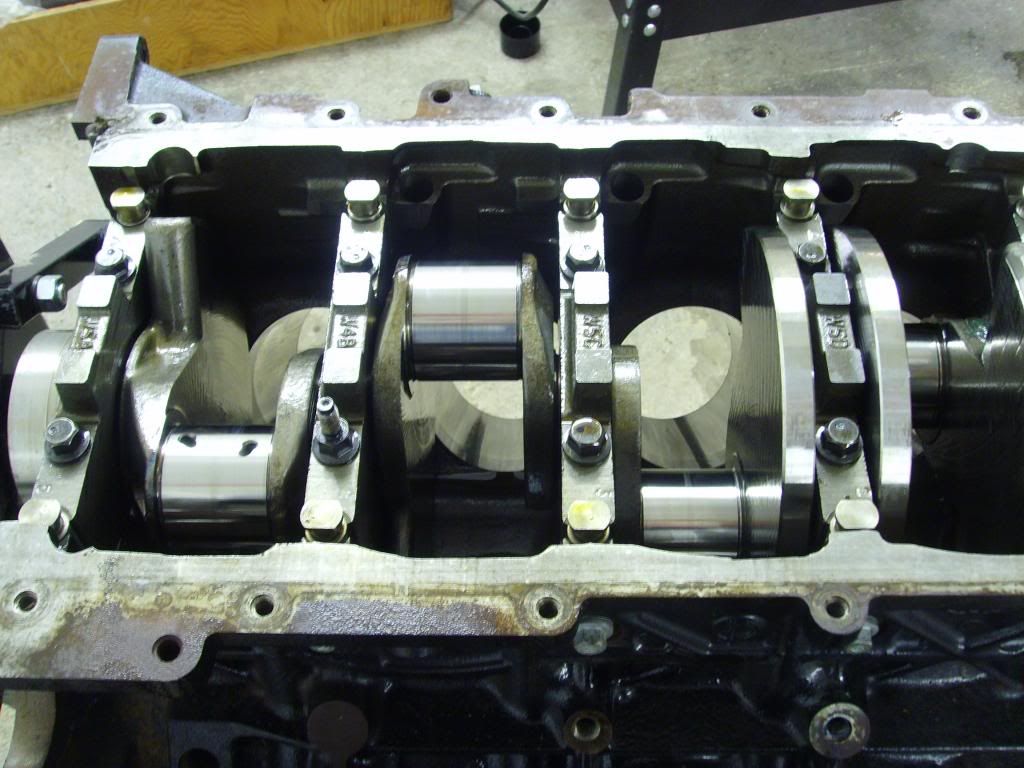

Block:

Heads:

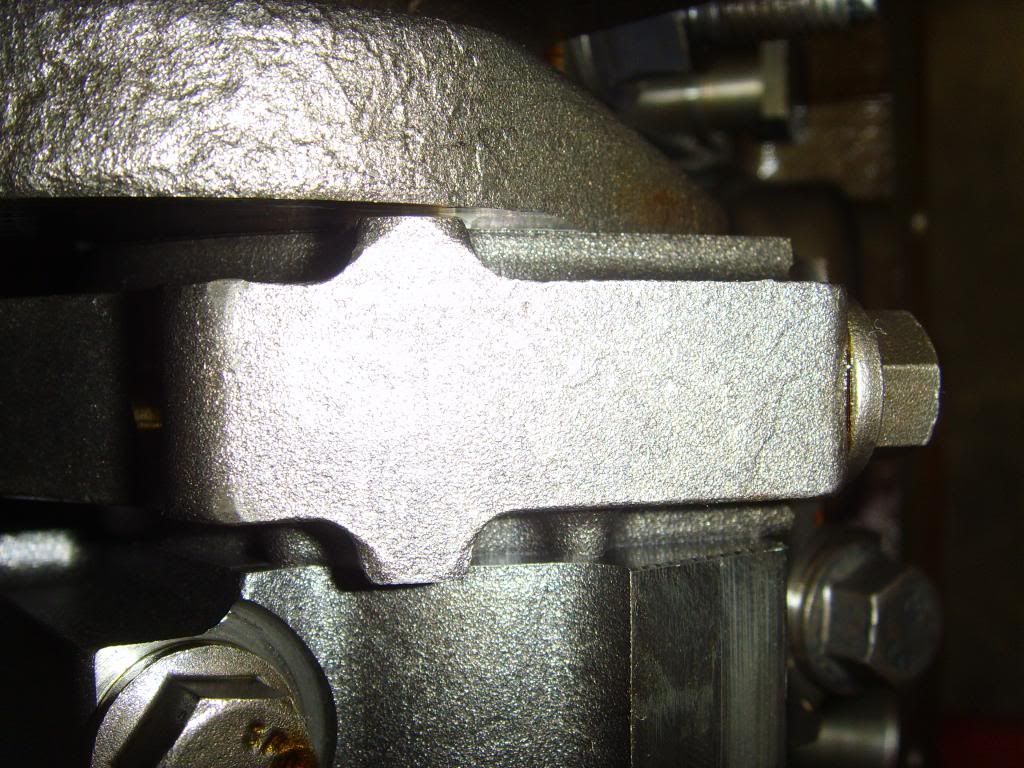

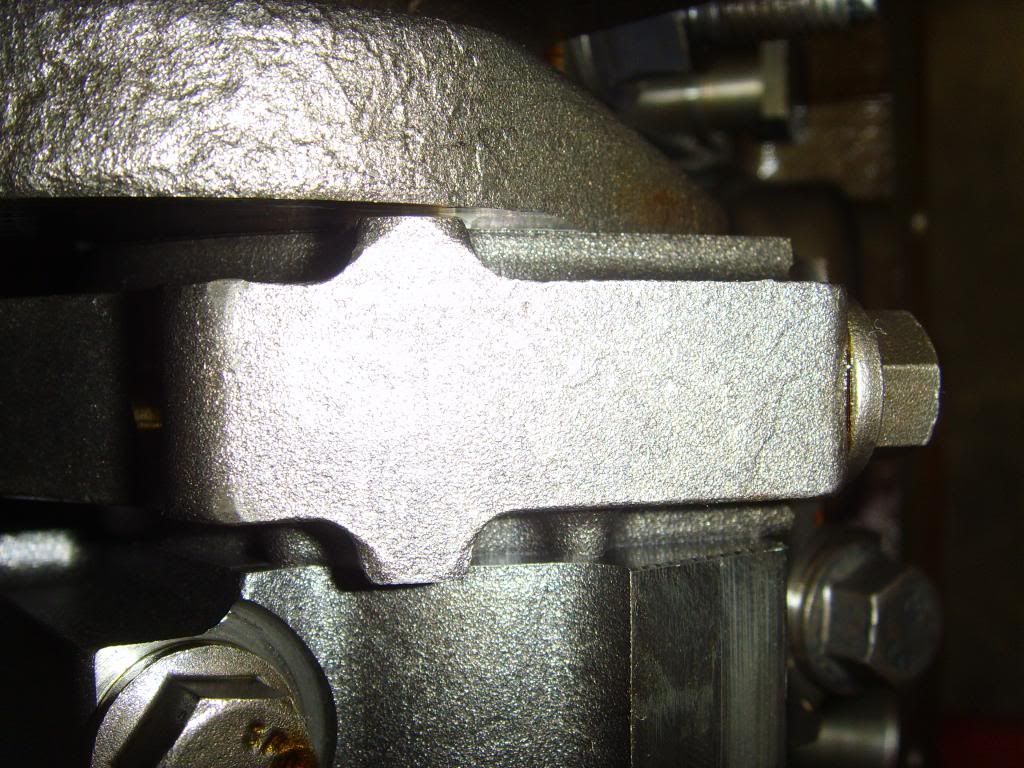

Started to strip: Cold crack Big end caps. Guess the gap, win a prize!

Pistons: Big ends are just like brand new.

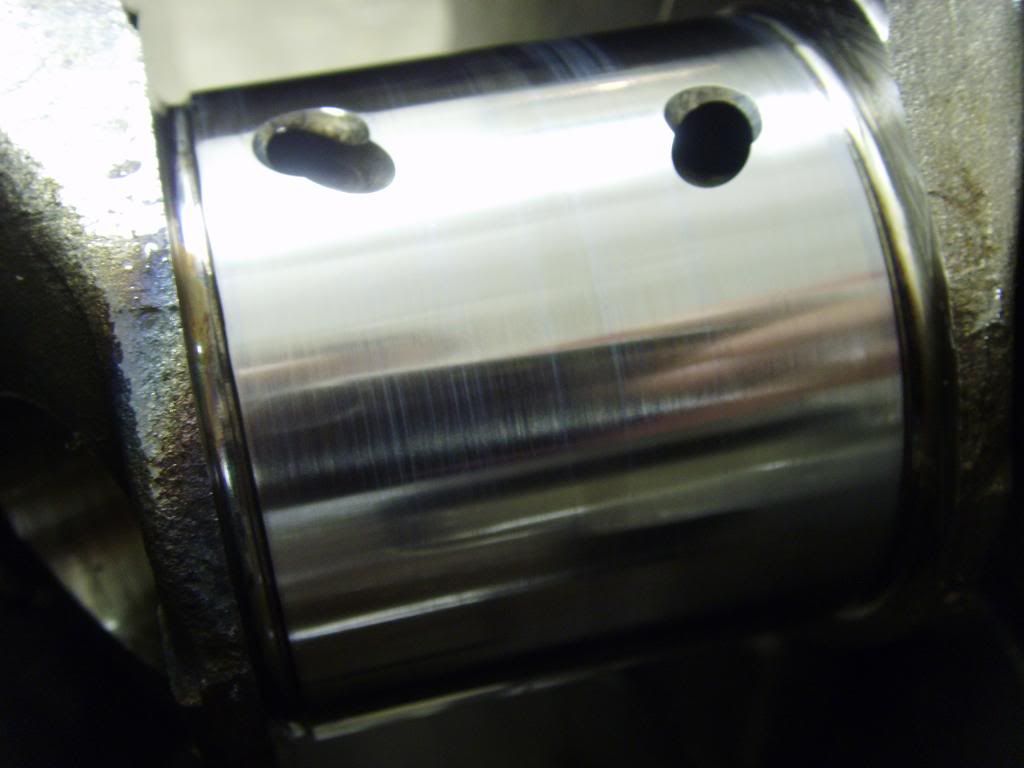

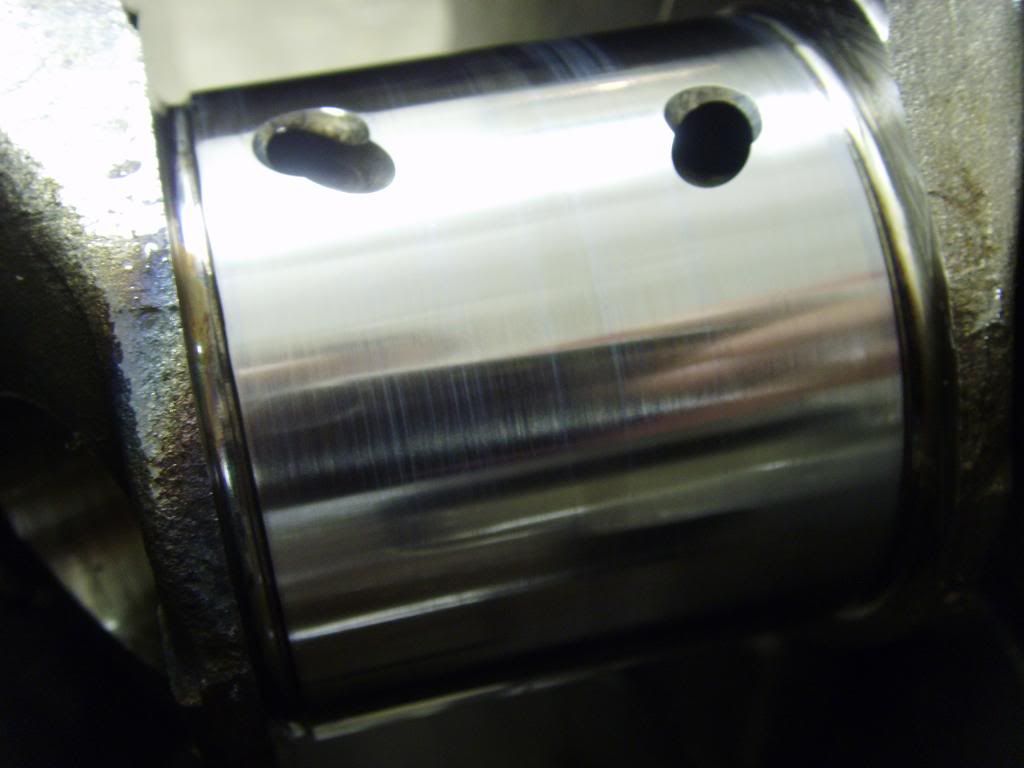

Crank shaft journals: Forged crank!

Shame to tear such a nice engine apart. Totally no wear, signs of wear or any indication that wear will arise.

Stripping Heads:

Heads: Havent got a Valve spring compressor and dont think the 'Deep socket & Hammer' trick will work on all 24.

Heads are getting a Custom Port & Polish soon enough.

The bare block is already in a crate and will be sent away, hot dipped and might have the Mains line honed to accommodate the ARP Mains.

Heads:

Started to strip: Cold crack Big end caps. Guess the gap, win a prize!

Pistons: Big ends are just like brand new.

Crank shaft journals: Forged crank!

Shame to tear such a nice engine apart. Totally no wear, signs of wear or any indication that wear will arise.

Stripping Heads:

Heads: Havent got a Valve spring compressor and dont think the 'Deep socket & Hammer' trick will work on all 24.

Heads are getting a Custom Port & Polish soon enough.

The bare block is already in a crate and will be sent away, hot dipped and might have the Mains line honed to accommodate the ARP Mains.

Last edited by .Ross.; 03-01-2013 at 08:41 AM.

#46

Thread Starter

Advanced PassionFord User

iTrader: (2)

Joined: Apr 2009

Posts: 2,229

Likes: 0

From: BC, Canada

More parts.

First off the 2.3ltr TwinScrew supercharger.

Fore precision triple pump fuel hat (Flash as fuck) gonna run 8-AN straight through.

Metco bullet idler pulleys.

Meziere Electric water pump.

Probably gonna start building soon. Custom made inlet plenum so I can bolt a Whipple 1950cfm mono blade TB on there.

First off the 2.3ltr TwinScrew supercharger.

Fore precision triple pump fuel hat (Flash as fuck) gonna run 8-AN straight through.

Metco bullet idler pulleys.

Meziere Electric water pump.

Probably gonna start building soon. Custom made inlet plenum so I can bolt a Whipple 1950cfm mono blade TB on there.

#47

Thread Starter

Advanced PassionFord User

iTrader: (2)

Joined: Apr 2009

Posts: 2,229

Likes: 0

From: BC, Canada

Well I thought IDE kill more time and post an update for all the followers of my custom build lol.

Anyhow, The Standard Whipple Inlet elbow and Stock TB are restrictive and limits HP to around 650 to the wheels.

So bought this Lightning Elbow that's a little more flowing and affords the use of the Mustang Fly-By-Wire TB.

By-Pass don't line up. You can also see the quality difference between to two.

Made a plate, 1/2 thick, Drilled and tapped the holes.

Am gonna cut and join them together.

Anyhow, The Standard Whipple Inlet elbow and Stock TB are restrictive and limits HP to around 650 to the wheels.

So bought this Lightning Elbow that's a little more flowing and affords the use of the Mustang Fly-By-Wire TB.

By-Pass don't line up. You can also see the quality difference between to two.

Made a plate, 1/2 thick, Drilled and tapped the holes.

Am gonna cut and join them together.

#48

Thread Starter

Advanced PassionFord User

iTrader: (2)

Joined: Apr 2009

Posts: 2,229

Likes: 0

From: BC, Canada

Nervy about cutting $$$$ worth of Whipple Richard.

Bolts to the plate perfect. The pic is forgiving, they don't line up perfect.

The kid who is welding the pieces don't come on shift till Sunday.

Not a Credit card in site

Bolts to the plate perfect. The pic is forgiving, they don't line up perfect.

The kid who is welding the pieces don't come on shift till Sunday.

Not a Credit card in site

#49

Thread Starter

Advanced PassionFord User

iTrader: (2)

Joined: Apr 2009

Posts: 2,229

Likes: 0

From: BC, Canada

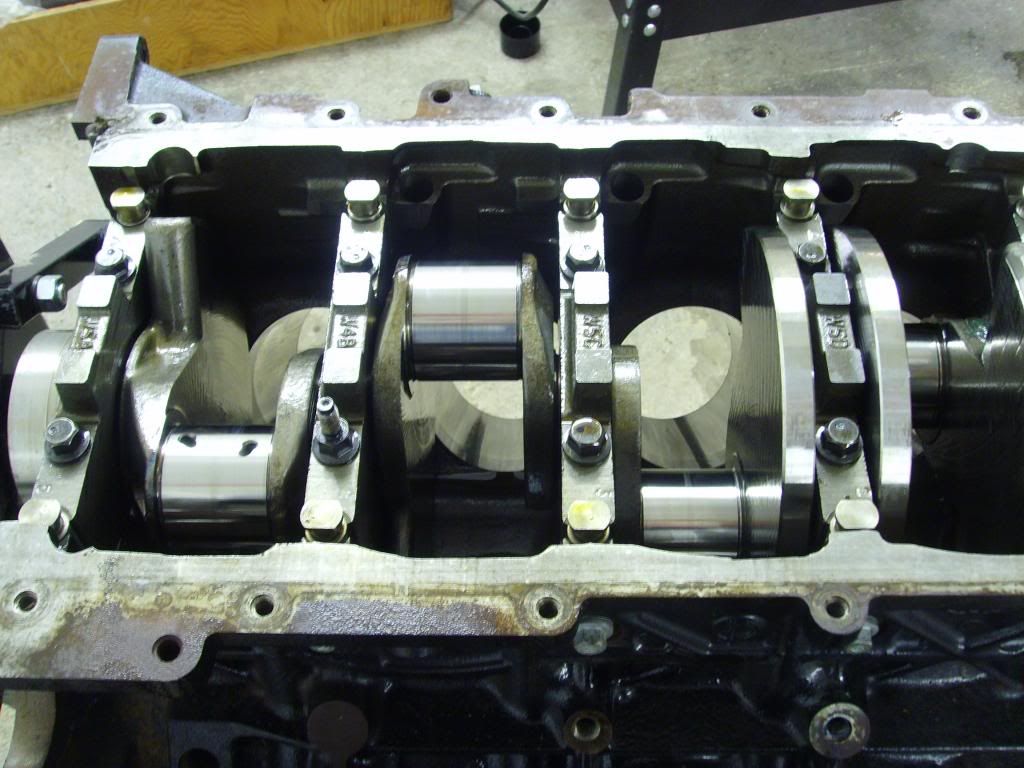

Picked the short block up yesterday.

Gonna stay in the crate until needed.

• 09 5.4 3v block.

• Polished, lightened & Balanced Crank (Forged)

• Manley 18CC Pistons. (Pots machined to each slug)

• Manley SS rings. Gapped for allot of boost.

• Manley H-Beam Rods, ARP 2000.

• Clevite Bearings, Crank / Rods matched.

• ARP Mains, Main hone.

• ARP Side bolts.

Pretty much the real deal.

The builder said it will provide 800HP all day, every day. He even mentioned 1000HP no worries.

Because of the rings it hardly needs any run in.

I understand that allot of this is just 'Gobbly gook' to most but believe me. This block is now the real deal.

Gonna stay in the crate until needed.

• 09 5.4 3v block.

• Polished, lightened & Balanced Crank (Forged)

• Manley 18CC Pistons. (Pots machined to each slug)

• Manley SS rings. Gapped for allot of boost.

• Manley H-Beam Rods, ARP 2000.

• Clevite Bearings, Crank / Rods matched.

• ARP Mains, Main hone.

• ARP Side bolts.

Pretty much the real deal.

The builder said it will provide 800HP all day, every day. He even mentioned 1000HP no worries.

Because of the rings it hardly needs any run in.

I understand that allot of this is just 'Gobbly gook' to most but believe me. This block is now the real deal.

Last edited by .Ross.; 01-03-2013 at 07:53 AM.

#54

Thread Starter

Advanced PassionFord User

iTrader: (2)

Joined: Apr 2009

Posts: 2,229

Likes: 0

From: BC, Canada

Thanks Carlos.

I don't care who you are! This is fucking COOL!

GT500 Mono blade TB that can flow 1950cfm.

It don't fit but that's not a problem.

I don't care who you are! This is fucking COOL!

GT500 Mono blade TB that can flow 1950cfm.

It don't fit but that's not a problem.

Last edited by .Ross.; 12-03-2013 at 09:21 PM.

#56

Thread Starter

Advanced PassionFord User

iTrader: (2)

Joined: Apr 2009

Posts: 2,229

Likes: 0

From: BC, Canada

You can buy adaptor plates but don't work as the original Mustang / GT500 TB uses two butterfly's.

So I will grab a piece of aluminim plate and taper it to fit both ends. Hollow the plate out so this mono blade will rotate.

Weld the plate to the Donkey Dick and bolt this TB right on there.

OR! Iam in talks with a guy about swapping this Whipple GT500 Mono Blade for his Whipple GT mono blade TB

It would require work also but hardly any. The GT TB only flows 1750cfm

It would require work also but hardly any. The GT TB only flows 1750cfm

#58

The GT500 TB is slightly wider than a Mustang GT.

You can buy adaptor plates but don't work as the original Mustang / GT500 TB uses two butterfly's.

So I will grab a piece of aluminim plate and taper it to fit both ends. Hollow the plate out so this mono blade will rotate.

Weld the plate to the Donkey Dick and bolt this TB right on there.

OR! Iam in talks with a guy about swapping this Whipple GT500 Mono Blade for his Whipple GT mono blade TB It would require work also but hardly any. The GT TB only flows 1750cfm

It would require work also but hardly any. The GT TB only flows 1750cfm

You can buy adaptor plates but don't work as the original Mustang / GT500 TB uses two butterfly's.

So I will grab a piece of aluminim plate and taper it to fit both ends. Hollow the plate out so this mono blade will rotate.

Weld the plate to the Donkey Dick and bolt this TB right on there.

OR! Iam in talks with a guy about swapping this Whipple GT500 Mono Blade for his Whipple GT mono blade TB

It would require work also but hardly any. The GT TB only flows 1750cfm

It would require work also but hardly any. The GT TB only flows 1750cfm

#59

Thread Starter

Advanced PassionFord User

iTrader: (2)

Joined: Apr 2009

Posts: 2,229

Likes: 0

From: BC, Canada

The S331 is a nice truck. Everything about them is just cool (only RWD) It uses the same case and rotors as this 2.3. Although they under mount the blower. This unit pumps 2.3 litres of air per turn

Yeah I could jigg it to work but might as well use the machine shop and custom fit this correct.

The GT TB would be enough for crazy amounts of power.

Yeah I could jigg it to work but might as well use the machine shop and custom fit this correct.

The GT TB would be enough for crazy amounts of power.

#61

Thread Starter

Advanced PassionFord User

iTrader: (2)

Joined: Apr 2009

Posts: 2,229

Likes: 0

From: BC, Canada

Yeah just forgot to update this thread.

Bought a 3v GT TB. It just fits lovely. Sold the GT500 TB a while back.

Started to port te inlet but its gonna need more work.

This one is claimed to flow 1750cfm.

I have around 1/2 - 3/4 clearance between the head unit & TPS. MMM that's nice that some thing fits without needing cutting/hammering/bending/welding.

Have this die grinder. Gonna finish the port with it later. I might even give the turkey pan and discharge plate a going over.

Bought a 3v GT TB. It just fits lovely. Sold the GT500 TB a while back.

Started to port te inlet but its gonna need more work.

This one is claimed to flow 1750cfm.

I have around 1/2 - 3/4 clearance between the head unit & TPS. MMM that's nice that some thing fits without needing cutting/hammering/bending/welding.

Have this die grinder. Gonna finish the port with it later. I might even give the turkey pan and discharge plate a going over.

#63

Thread Starter

Advanced PassionFord User

iTrader: (2)

Joined: Apr 2009

Posts: 2,229

Likes: 0

From: BC, Canada

Changed the blower snout. Not, I repeat NOT an easy task. No documented guide or even a pic of this! Whipple should provide exploded diagrams on there website at least.

Iam gonna run the Roush FEAD separate belt system.

Need to remove the big 10mm cap head from the centre. How? Jam a soft screwdriver in the screws.

Pull the adaptor then loosen the cap screws around the thingy flange. Then pull the main cover.

That bearing needs to come off then remove the drive gear.

After this I didn't document the hub removal as my hands are too gunky. The whole hub needs to be pulled from the 5 lobe shaft. This didn't slide off. In fact it was real tight. A few loud clinks (Oh I've broke the blower type clinks) and the whole thing came off. Don't forget to add timing marks.

Then we pressed the new timing hub on here and installed the drive gear. The hub is similar to the direct drive unit except the pins are longer. It's looks like the pins are threaded in. Again Whipple could have sold these pins? Would have saved me a ball ache timing the screws.

The direct drive set up.

Once I timed the screws (The gear has play to do this) we pulled the rotor pack. Conveniently they provide jacking threads in either corner.

The housing. Sealed bearings in the rear with spring washers.

The rotor pack. There's a few scratches on the screws. Only cosmetic. Something got "Screwed" Cannot feel them by touch. Nothing to worry about.

Hub installed. Erm nobody told me the new snout needed longer mounting bolts FFS!!!

Back in the warm. Mocked the 6 rib pulley on there for zhits & giggles.

That's about it lads. I had the FRPS welded onto the other side of the fuel rail. It hits the inlet.

Heads should be going away soon.

Am on the look out for a Regular cab as I don't think the SCREW will take 750BHP. something like this!

http://dealerrevs.com/gallery/38544567.html

Iam gonna run the Roush FEAD separate belt system.

Need to remove the big 10mm cap head from the centre. How? Jam a soft screwdriver in the screws.

Pull the adaptor then loosen the cap screws around the thingy flange. Then pull the main cover.

That bearing needs to come off then remove the drive gear.

After this I didn't document the hub removal as my hands are too gunky. The whole hub needs to be pulled from the 5 lobe shaft. This didn't slide off. In fact it was real tight. A few loud clinks (Oh I've broke the blower type clinks) and the whole thing came off. Don't forget to add timing marks.

Then we pressed the new timing hub on here and installed the drive gear. The hub is similar to the direct drive unit except the pins are longer. It's looks like the pins are threaded in. Again Whipple could have sold these pins? Would have saved me a ball ache timing the screws.

The direct drive set up.

Once I timed the screws (The gear has play to do this) we pulled the rotor pack. Conveniently they provide jacking threads in either corner.

The housing. Sealed bearings in the rear with spring washers.

The rotor pack. There's a few scratches on the screws. Only cosmetic. Something got "Screwed" Cannot feel them by touch. Nothing to worry about.

Hub installed. Erm nobody told me the new snout needed longer mounting bolts FFS!!!

Back in the warm. Mocked the 6 rib pulley on there for zhits & giggles.

That's about it lads. I had the FRPS welded onto the other side of the fuel rail. It hits the inlet.

Heads should be going away soon.

Am on the look out for a Regular cab as I don't think the SCREW will take 750BHP. something like this!

http://dealerrevs.com/gallery/38544567.html

Last edited by .Ross.; 27-05-2013 at 08:19 PM.

#70

Thread Starter

Advanced PassionFord User

iTrader: (2)

Joined: Apr 2009

Posts: 2,229

Likes: 0

From: BC, Canada

Thanks allot fellas.

Glenn: Doing great mate. Have a right 'Happy family' vibe going at

The moment.

Ah well. Project 'Will it ever be done' has inched a little closer.

I was in me shop the other day looking for something and I found the 'Whipple supplied 3v MAF housing'. Having studied it for a while.

I came to the conclusion that the Whipple kit is so expensive new because of the excessive amount of Aluminium used in this piece.

So I called a friend who's old man has a rather tasty Lathe in his garage.

This is the result.

This is the OE whipple transition boot from the lightning plastic elbow to MAF.

So the original size was 86mm. It's now 96mm. That should be good for the 600RWHP goals? Maybe I will need an SCT5000 MAF so the OEM don't peg.

The beauty of it all its cost very little. A 12 pack of Coors. I much prefer BUILT, Not Bought!

Just came off night shift at the mine. Not ideal weather conditions.

Glenn: Doing great mate. Have a right 'Happy family' vibe going at

The moment.

Ah well. Project 'Will it ever be done' has inched a little closer.

I was in me shop the other day looking for something and I found the 'Whipple supplied 3v MAF housing'. Having studied it for a while.

I came to the conclusion that the Whipple kit is so expensive new because of the excessive amount of Aluminium used in this piece.

So I called a friend who's old man has a rather tasty Lathe in his garage.

This is the result.

This is the OE whipple transition boot from the lightning plastic elbow to MAF.

So the original size was 86mm. It's now 96mm. That should be good for the 600RWHP goals? Maybe I will need an SCT5000 MAF so the OEM don't peg.

The beauty of it all its cost very little. A 12 pack of Coors. I much prefer BUILT, Not Bought!

Just came off night shift at the mine. Not ideal weather conditions.

#74

Thread Starter

Advanced PassionFord User

iTrader: (2)

Joined: Apr 2009

Posts: 2,229

Likes: 0

From: BC, Canada

Ey up Glenn.

Haven't updated this thread for a while.

Bought an 04 Reg Cab Stepside. The built motor will be going in this.

Mainly sorting the shop out. Got the compressor in. All 50 stones worth.

All the plumbing.

PS: I see some of the pics have been screwed up? Cannot be arsed to change/edit it all.

Haven't updated this thread for a while.

Bought an 04 Reg Cab Stepside. The built motor will be going in this.

Mainly sorting the shop out. Got the compressor in. All 50 stones worth.

All the plumbing.

PS: I see some of the pics have been screwed up? Cannot be arsed to change/edit it all.

Last edited by .Ross.; 06-05-2014 at 12:26 AM.

#76

Thread Starter

Advanced PassionFord User

iTrader: (2)

Joined: Apr 2009

Posts: 2,229

Likes: 0

From: BC, Canada

Thanks mate. It's 'Little Red Riding Hood'

And av never done a fucking thing to it for ages !

It's the summer time and the weather is fine.

I have bought a Blaze King wood stove for the house and put the super 27 in the shop.

Been cutting a shit load of firewood.

Enjoying the summer.

Drinking a shit load of beer.

The wife is expecting or second child Oct 13 so gonna take a shit load of paid Paternity leave as well.

Life is just great!!! How are you doing Glenn?

And av never done a fucking thing to it for ages !

It's the summer time and the weather is fine.

I have bought a Blaze King wood stove for the house and put the super 27 in the shop.

Been cutting a shit load of firewood.

Enjoying the summer.

Drinking a shit load of beer.

The wife is expecting or second child Oct 13 so gonna take a shit load of paid Paternity leave as well.

Life is just great!!! How are you doing Glenn?

Last edited by .Ross.; 28-08-2014 at 02:24 AM.

Thread

Thread Starter

Forum

Replies

Last Post

borboyous

Cars for Sale

6

22-08-2015 12:17 PM

track.focus'd

Restorations, Rebuilds & Projects.

26

12-08-2015 06:53 PM