2000hp Twin Turbo Ford 4.6L 32V V8 in the build in Australia

#41

the rods are here Carrillo took a little longer but i'm not going to complain they were the only ones that would do a custom set for me. as you can see in the pic below it is a much more stout rod than the Manley which can handle around 1500hp, the Carrillo's are good for 2000+hp. the rods where pretty much the only major thing stopping me from taking this up to around 2000hp, now it's not a problem. can get cracking on the engine now, everything is in.

the rods are here Carrillo took a little longer but i'm not going to complain they were the only ones that would do a custom set for me. as you can see in the pic below it is a much more stout rod than the Manley which can handle around 1500hp, the Carrillo's are good for 2000+hp. the rods where pretty much the only major thing stopping me from taking this up to around 2000hp, now it's not a problem. can get cracking on the engine now, everything is in.

#42

Nice rods !

My friend ran a 9.0 @ 148mph on all 3 of his shakedown runs at the weekend, not as fast as he hoped for now but still a lot to get familar with and when the power is there it should shift on quite well !

http://www.youtube.com/watch?v=sy2MlSSsXvA

My friend ran a 9.0 @ 148mph on all 3 of his shakedown runs at the weekend, not as fast as he hoped for now but still a lot to get familar with and when the power is there it should shift on quite well !

http://www.youtube.com/watch?v=sy2MlSSsXvA

#43

Nice rods !

My friend ran a 9.0 @ 148mph on all 3 of his shakedown runs at the weekend, not as fast as he hoped for now but still a lot to get familar with and when the power is there it should shift on quite well !

http://www.youtube.com/watch?v=sy2MlSSsXvA

My friend ran a 9.0 @ 148mph on all 3 of his shakedown runs at the weekend, not as fast as he hoped for now but still a lot to get familar with and when the power is there it should shift on quite well !

http://www.youtube.com/watch?v=sy2MlSSsXvA

#45

ths is from the Carrillo site ''Each connecting rod is manufactured from Carrilloloy, a proprietary blend of steels and alloys. The Pro-H with Carrillo Multiphase (CARR) Rod Bolts H-Beam connecting rods are the strongest rods available anywhere and are nearly indestructible. These rods are for extreme horsepower application that are performing at extreme heat and rpms''

which rod did you get? these are a custom made set, the other 4.6 ones Carrillo make don't have the thickness like these do, they look similar to the Manley ones i have in the picture. these have the CARR 3/8'' bolts which have a 285,000psi tensile rating. they don't have a HP rating, but the ones with the WMC bolts are rated at a minimum of 250hp, i would say these would be rated at 300+hp each.

which rod did you get? these are a custom made set, the other 4.6 ones Carrillo make don't have the thickness like these do, they look similar to the Manley ones i have in the picture. these have the CARR 3/8'' bolts which have a 285,000psi tensile rating. they don't have a HP rating, but the ones with the WMC bolts are rated at a minimum of 250hp, i would say these would be rated at 300+hp each.

Last edited by prasac; 30-03-2010 at 07:09 AM.

#46

ths is from the Carrillo site ''Each connecting rod is manufactured from Carrilloloy, a proprietary blend of steels and alloys. The Pro-H with Carrillo Multiphase (CARR) Rod Bolts H-Beam connecting rods are the strongest rods available anywhere and are nearly indestructible. These rods are for extreme horsepower application that are performing at extreme heat and rpms''

which rod did you get? these are a custom made set, the other 4.6 ones Carrillo make don't have the thickness like these do, they look similar to the Manley ones i have in the picture. these have the CARR 3/8'' bolts which have a 285,000psi tensile rating. they don't have a HP rating, but the ones with the WMC bolts are rated at a minimum of 250hp, i would say these would be rated at 300+hp each.

which rod did you get? these are a custom made set, the other 4.6 ones Carrillo make don't have the thickness like these do, they look similar to the Manley ones i have in the picture. these have the CARR 3/8'' bolts which have a 285,000psi tensile rating. they don't have a HP rating, but the ones with the WMC bolts are rated at a minimum of 250hp, i would say these would be rated at 300+hp each.

They will even survive armageddon, when that day comes!

#47

#48

Crower make some great stuff. i was going to get the Manley 300M like Accufab uses i know they will handle 2500hp but Manley only had 7 left  , i had to make an order of 40 for them to make figured Carrillo would do a great job anyway, tried to go Aluminium unfortunately our bores are too small to get a good aluminium rod made

, i had to make an order of 40 for them to make figured Carrillo would do a great job anyway, tried to go Aluminium unfortunately our bores are too small to get a good aluminium rod made

Looking forward to hearing about your dyno run!!

#49

I think its a few months until the next meet but I'll start a thread about the car and drop you the link.

#50

#53

#54

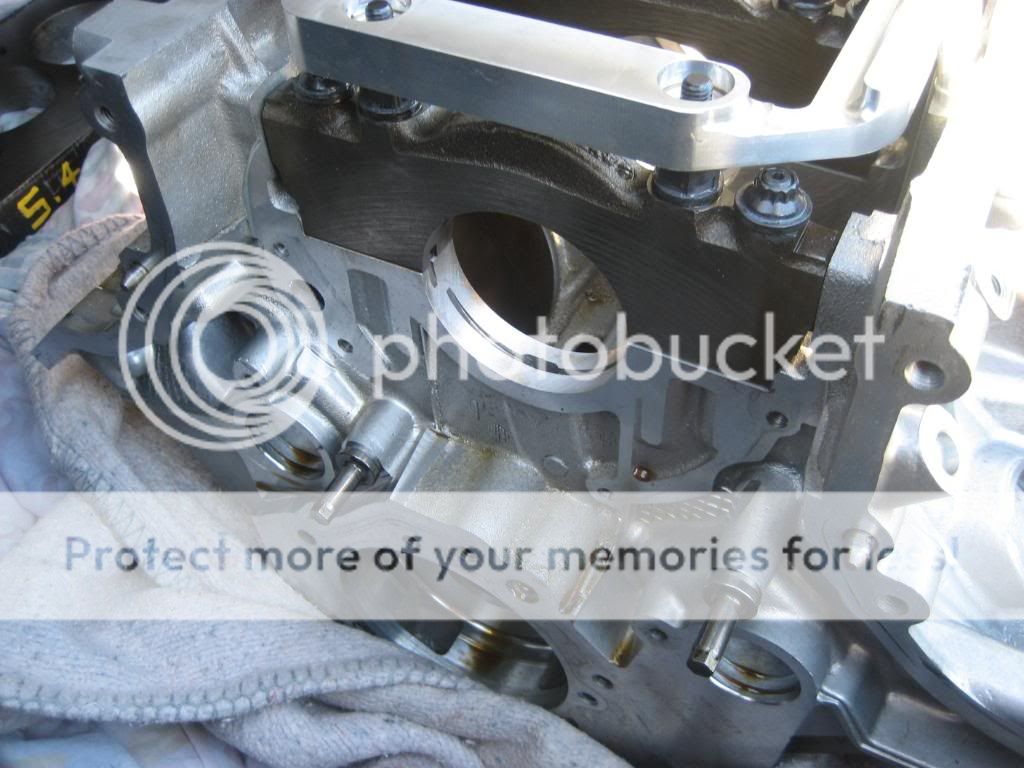

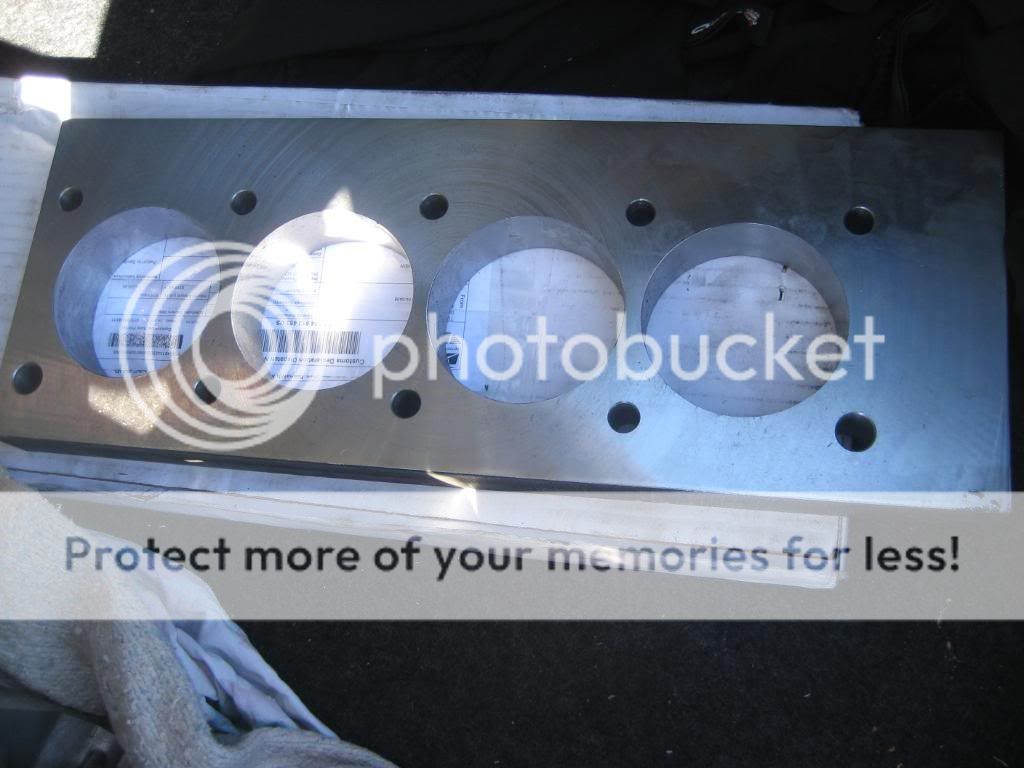

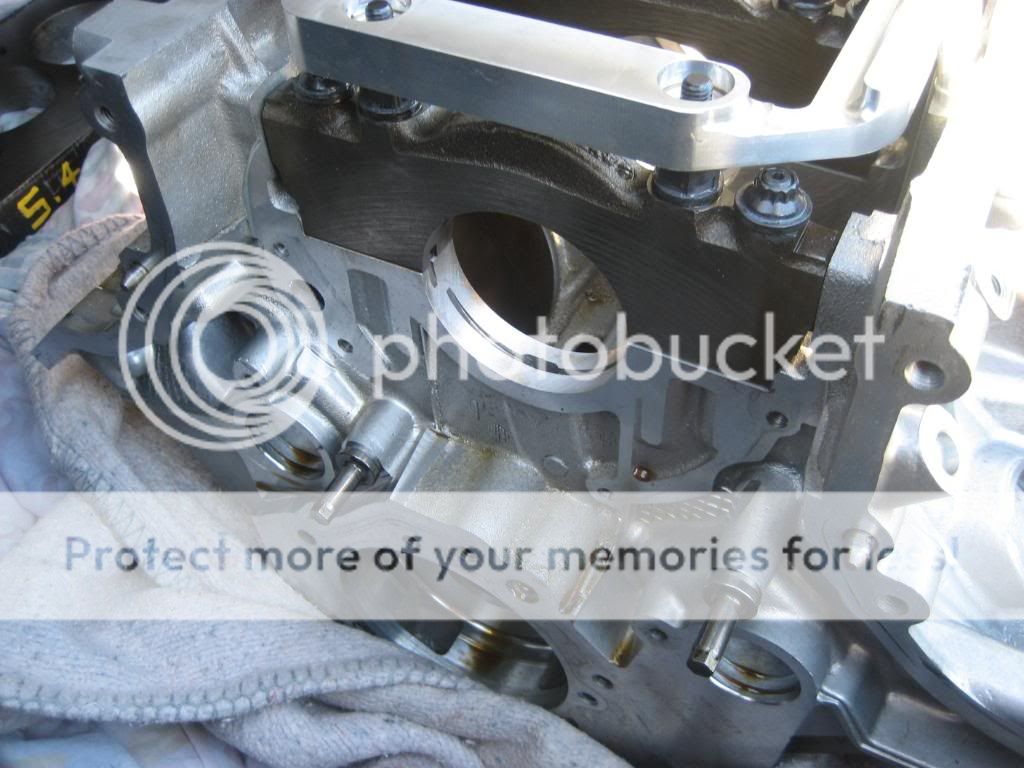

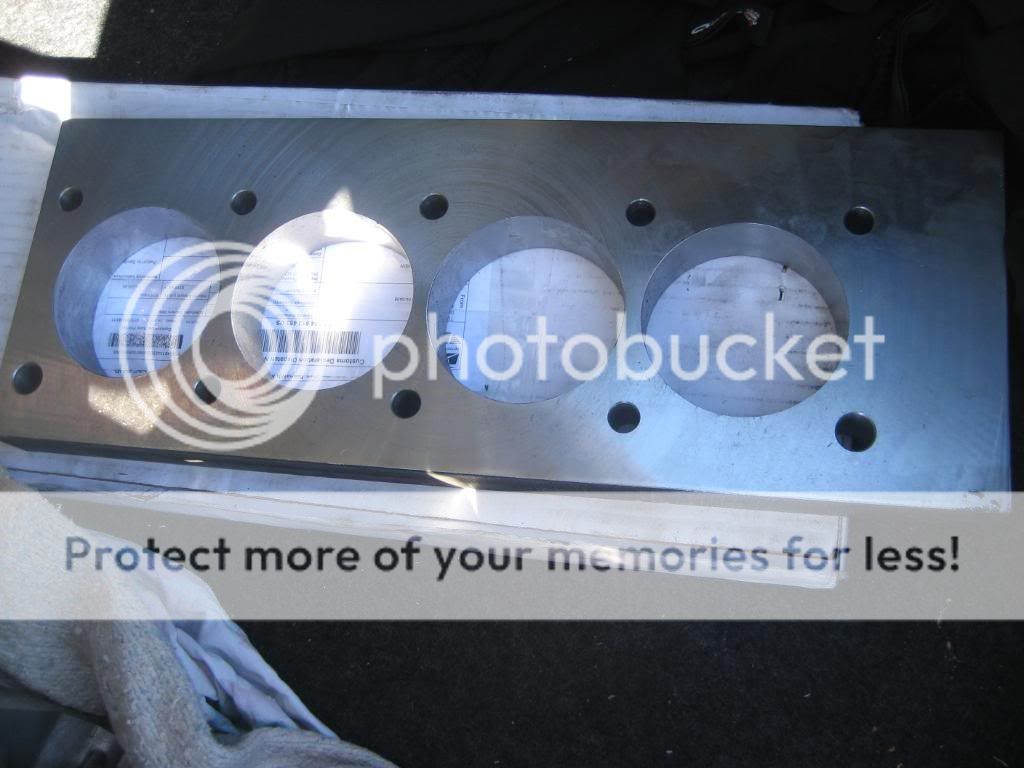

picked up the block today from Westend Performance took it back to Norm's, they line honed it, torqued it all up, cut out the girdle for the drainback tubes to come out and drilled and tapped the side for a thicker longer bolt. can't get the crank scraper in but i'm positive with just the drainback tubes it will be fine, the scraper was more of an extra just in case. Westend were nice enough to loan me a torque and had another one made up, the torque plates are imperative when screwing the modular engines together as there can be quite alot of movement, 99% of places won't use the torque plates. don't let the size of them fool you they would have to weigh close 20kg ea. a fully loaded cylinder head weighs around 50lbs. Norm will finish filling it tomorrow then it's back down to Westend to bore it. should only be there a couple days then we can screw it together. with a smooth run, within the fortnight it will be together.

ordering some L19 headstuds and am organising another set of heads to be done which will be O-ringed and will use copper gaskets instead of the Cometic/Fel-Pro. i am taking her up to a big meet in August and intend on pushing her a little bit harder pumping boost up to 40-42psi which is closer to what the turbo's really start working at, it should see a little over 2000hp at that boost.

torque plate

ordering some L19 headstuds and am organising another set of heads to be done which will be O-ringed and will use copper gaskets instead of the Cometic/Fel-Pro. i am taking her up to a big meet in August and intend on pushing her a little bit harder pumping boost up to 40-42psi which is closer to what the turbo's really start working at, it should see a little over 2000hp at that boost.

torque plate

#55

ok guys n gals a lil update, the block is down at the machinists, been there for the last week or so. waiting to have the cylinder bores honed and the crank micro-polished. the pistons will have around a .0045-.005'' clearance and we will be running around a 11-11.5:1 compression, could go higher being on methanol but am going to leave it reasonable enough to be streetable when i finish with it. i decided to go some heavy duty secondary chains as the factory 4.6/5.4L chains are known to break, i will be revving it to around 8500rpm so better safe than sorry. by any luck i will have the engine back on Friday and we can hook into next week and have it all done. the electrician will be here the following week to wire it all up. i have booked in for a Private Test Day @ WSID in July so i have to get cracking to have it all done. won't be going too hardcore on the day, will only be doing 60', 330' and 1/2 track passes make sure we have the chassis sorted, will be running it on 15lbs and 22lbs of boost, even on that boost it should still be making decent power in the vicinity of 900-1200hp, this is a very small car so we have to get it right before we can screw it up to 35+lbs.

the chains (left to right) factory, aftermarket and the upgraded heavy duty.

the chains (left to right) factory, aftermarket and the upgraded heavy duty.

#59

thanks guys

not much new to report, still waiting on the machining to get done, they have quite a few engines in having some work done so i have to wait, they said they would be done this week, so hopefully can pick it up later this week and get cracking. im confident we will have it altogether by the Private Test Day on the 19th July and the Ford Drag Nationals on the 24th July.

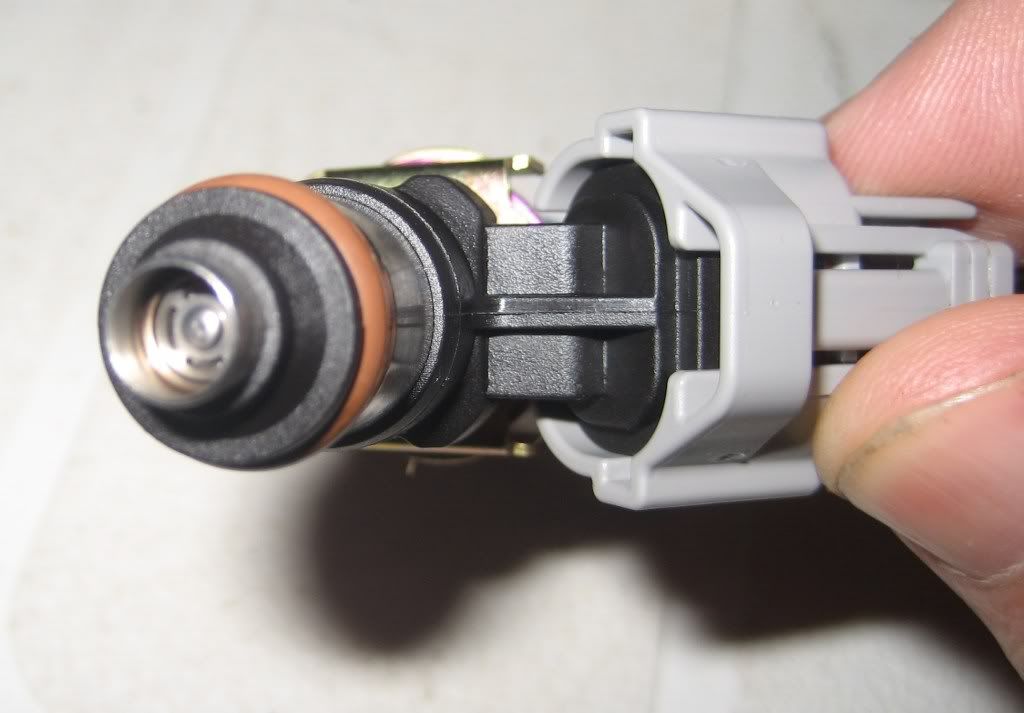

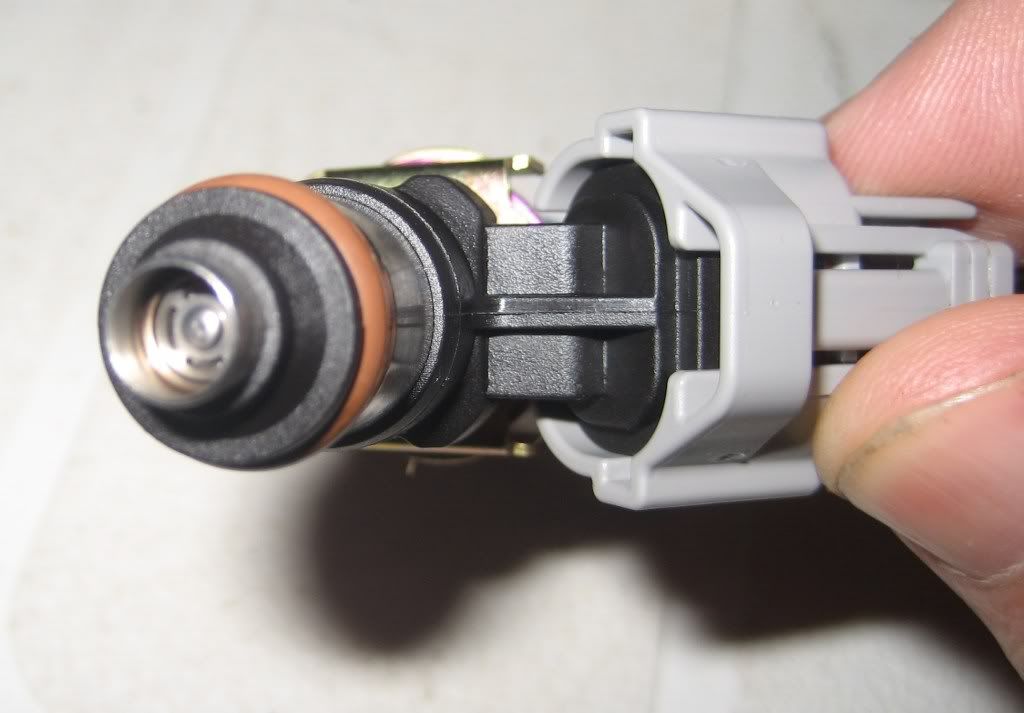

have been ordering all the little goodies i need and organising everything with Shane Tecklenburg (the tuner). got the injectors the other day, i was going to take the purple adapter off and get them done black but can't be bothered as have to replace the filter's etc and its a drag car not a show car , i am using 16 x Injector Dynamics ID2000's (2200cc actually) to handle the methanol. i need a set of these on my mouth to handle my alcohol injection

, i am using 16 x Injector Dynamics ID2000's (2200cc actually) to handle the methanol. i need a set of these on my mouth to handle my alcohol injection  they are a very impressive injector and all have been flow matched within 1% of each other. Shane has been involved with them since day one and soon as he tuned his first car with them, he was like ''you gotta get these'' he tunes anything from boats to 3500hp twin turbo drag cars using the ID2000's.

they are a very impressive injector and all have been flow matched within 1% of each other. Shane has been involved with them since day one and soon as he tuned his first car with them, he was like ''you gotta get these'' he tunes anything from boats to 3500hp twin turbo drag cars using the ID2000's.

the way the car is being tuned has interested alot of people. it's being ''remote tuned'' what that means is, its being done over the internet. Shane lives in the US and i don't have the cash to fly him over to Australia to tune the car, so that's where a remote tune comes in handy, it can be done by him anytime, anywhere in the world, he doesn't have to be at the dyno or track to do it, all he does is takes control of my computer when its hooked into the ECU/dyno etc and with the speed of the wireless internet these days he gets real time data. he has even tuned them on 56K connections. it's practically like him being there, i think this may be the way of the future for tuning.

some pics of the ID2000's, they are alot smaller than u would expect, i didn't have any of my Indy Blues around to show you.

not much new to report, still waiting on the machining to get done, they have quite a few engines in having some work done so i have to wait, they said they would be done this week, so hopefully can pick it up later this week and get cracking. im confident we will have it altogether by the Private Test Day on the 19th July and the Ford Drag Nationals on the 24th July.

have been ordering all the little goodies i need and organising everything with Shane Tecklenburg (the tuner). got the injectors the other day, i was going to take the purple adapter off and get them done black but can't be bothered as have to replace the filter's etc and its a drag car not a show car

, i am using 16 x Injector Dynamics ID2000's (2200cc actually) to handle the methanol. i need a set of these on my mouth to handle my alcohol injection

, i am using 16 x Injector Dynamics ID2000's (2200cc actually) to handle the methanol. i need a set of these on my mouth to handle my alcohol injection  they are a very impressive injector and all have been flow matched within 1% of each other. Shane has been involved with them since day one and soon as he tuned his first car with them, he was like ''you gotta get these'' he tunes anything from boats to 3500hp twin turbo drag cars using the ID2000's.

they are a very impressive injector and all have been flow matched within 1% of each other. Shane has been involved with them since day one and soon as he tuned his first car with them, he was like ''you gotta get these'' he tunes anything from boats to 3500hp twin turbo drag cars using the ID2000's. the way the car is being tuned has interested alot of people. it's being ''remote tuned'' what that means is, its being done over the internet. Shane lives in the US and i don't have the cash to fly him over to Australia to tune the car, so that's where a remote tune comes in handy, it can be done by him anytime, anywhere in the world, he doesn't have to be at the dyno or track to do it, all he does is takes control of my computer when its hooked into the ECU/dyno etc and with the speed of the wireless internet these days he gets real time data. he has even tuned them on 56K connections. it's practically like him being there, i think this may be the way of the future for tuning.

some pics of the ID2000's, they are alot smaller than u would expect, i didn't have any of my Indy Blues around to show you.

#61

#65

thanks guys, the fabricator is excellent definitely worth his weight in gold.

the engine is STILL at the machinists they have been busy lately and mine has been sitting around, we had a couple small hiccups. hopefully the engine will be finished off this week

they have been busy lately and mine has been sitting around, we had a couple small hiccups. hopefully the engine will be finished off this week

1) we got the wrong bearings, i didn't check the part number we got LS1 bearings instead of Ford 4.6 bearings it was an honest mistake, the part number on the Ford is MS2198 and the LS1 was MS2199, silly making part numbers of 2 different make engines so close. that

2) one of the pistons hits the crank counterweight so we have to shave a bit off.

3) when we filled the block, some cement got into 1 of the head stud holes and cemented the head stud in there and was a mongrel to get out and caused a bit of damage.

4) we filled the block up about 3-5mm's too high and blocked off one of the water passages, its difficult to get in there to clean it all out, so we might have to tap the back of one of the cylinders to divert the water. i wanted to leave about 1/4 unfilled so i can use the block in my street car. looking back i should have just filled the whole block and got another block for when i do the street car

the engine is STILL at the machinists

1) we got the wrong bearings, i didn't check the part number we got LS1 bearings instead of Ford 4.6 bearings it was an honest mistake, the part number on the Ford is MS2198 and the LS1 was MS2199, silly making part numbers of 2 different make engines so close. that

2) one of the pistons hits the crank counterweight so we have to shave a bit off.

3) when we filled the block, some cement got into 1 of the head stud holes and cemented the head stud in there and was a mongrel to get out and caused a bit of damage.

4) we filled the block up about 3-5mm's too high and blocked off one of the water passages, its difficult to get in there to clean it all out, so we might have to tap the back of one of the cylinders to divert the water. i wanted to leave about 1/4 unfilled so i can use the block in my street car. looking back i should have just filled the whole block and got another block for when i do the street car

Last edited by prasac; 17-06-2010 at 12:50 AM.

#66

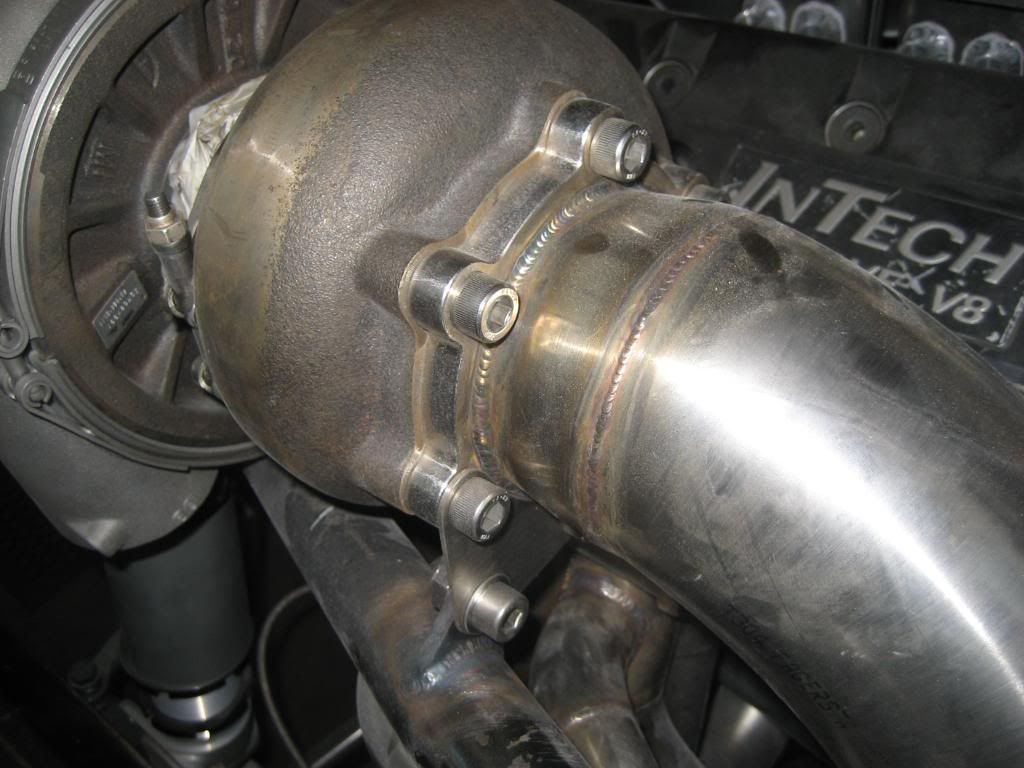

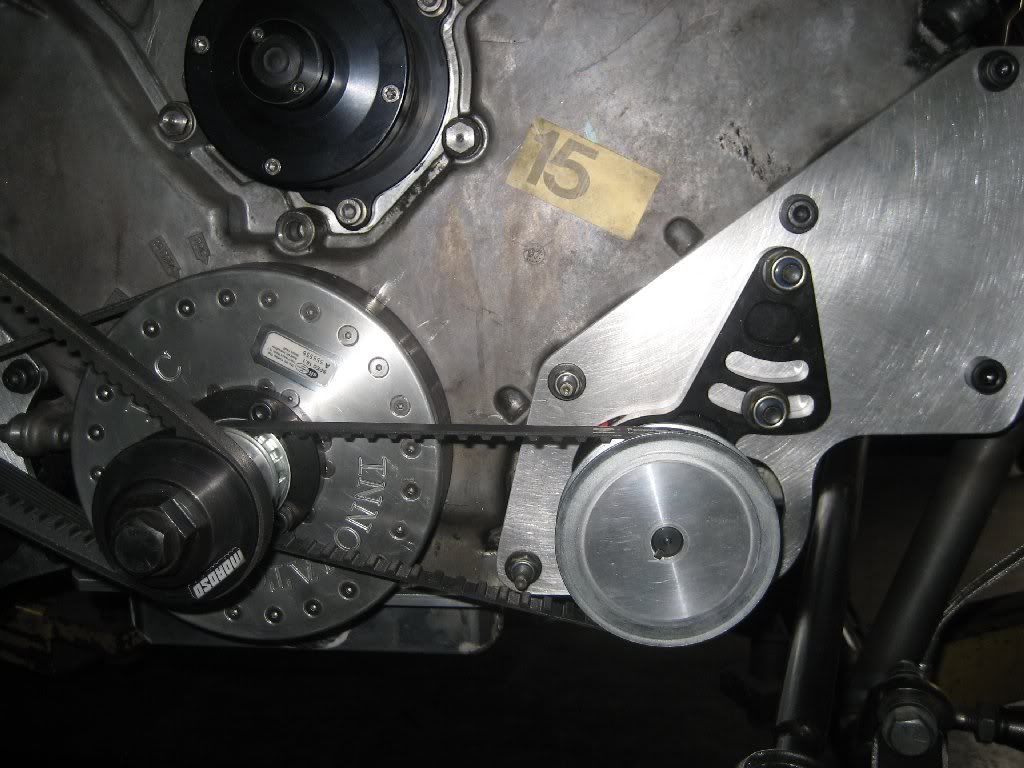

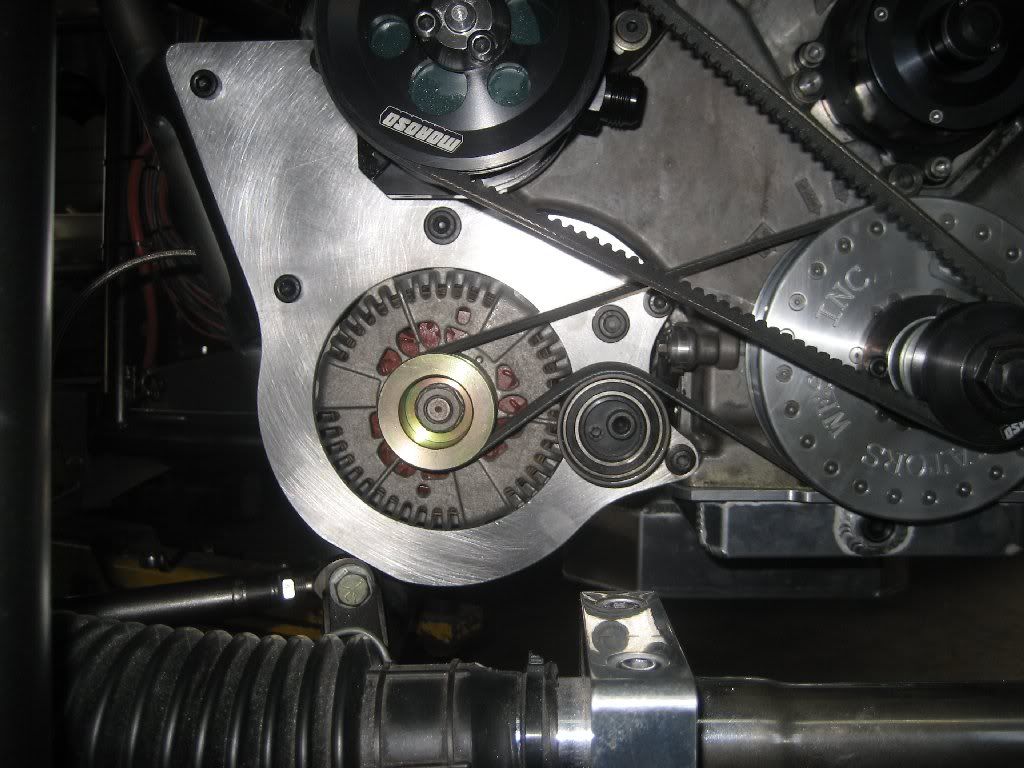

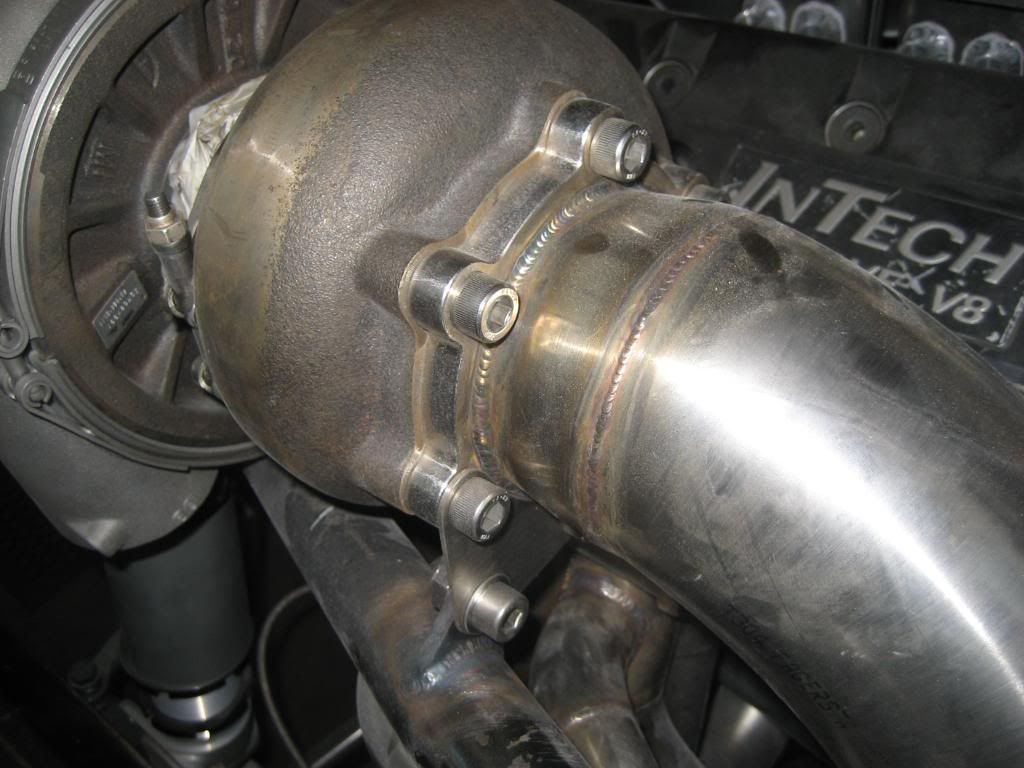

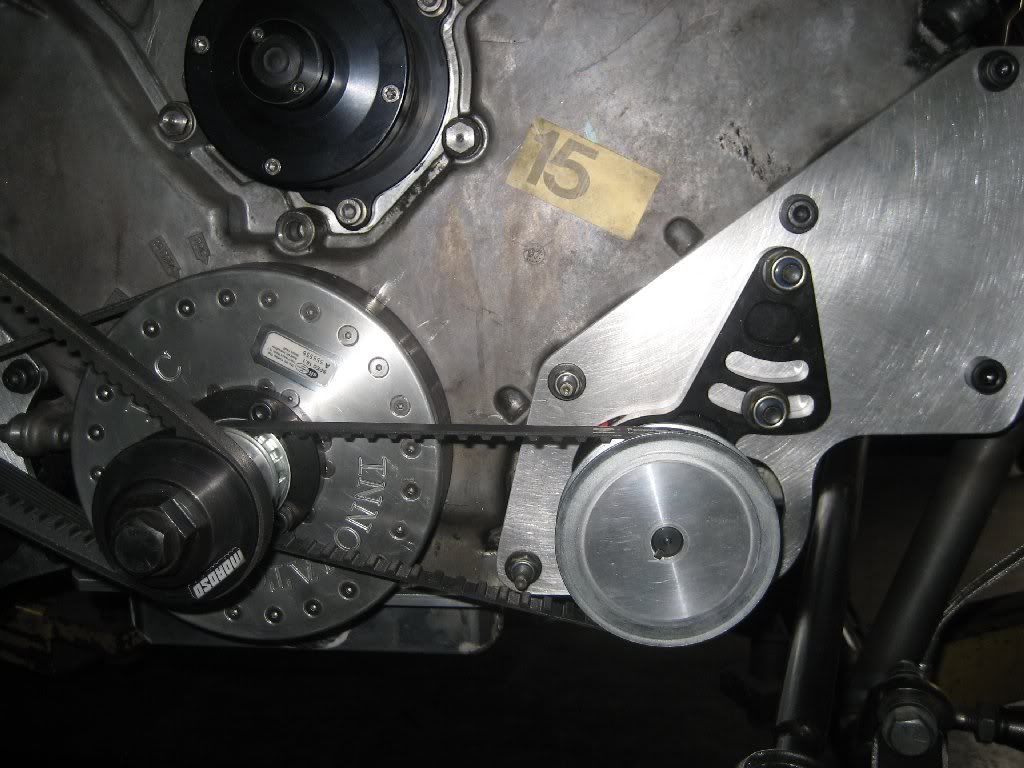

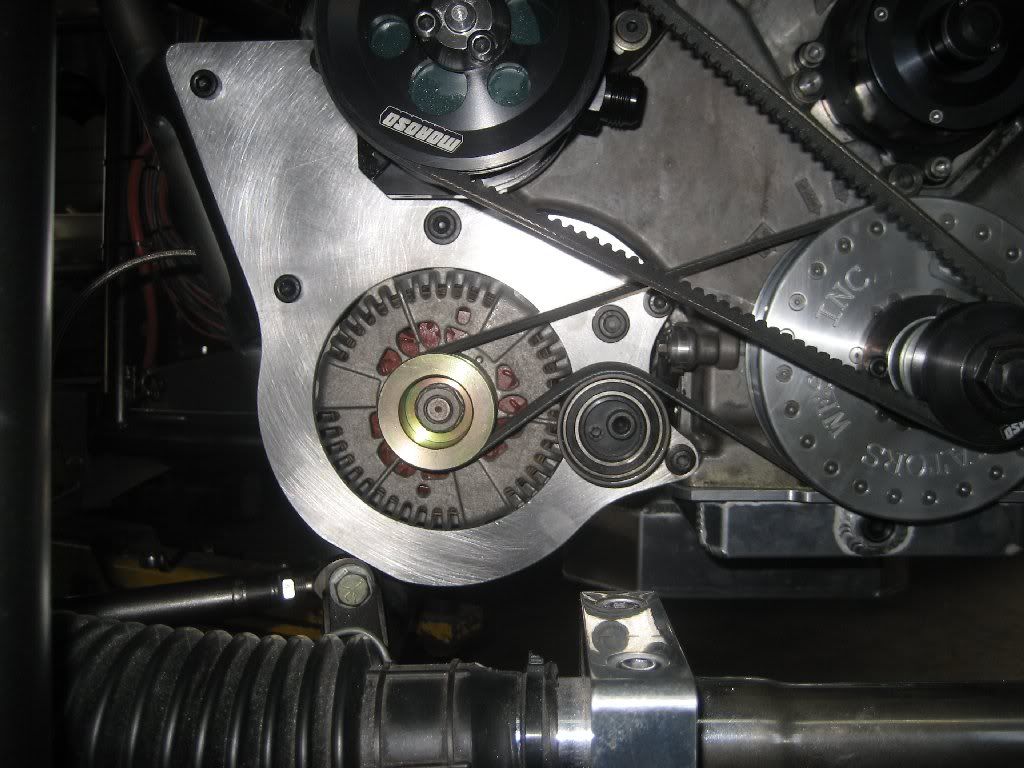

here are some more pics from the build. what is amazing about the fabricator he does everything from home in his shed. he is a one-stop shop and can do everything from a bracket to building a full tube chassis. he doesn't have the $100,000+ tools big shops have, he uses his brain and when something is needed he designs a tool to make it

Last edited by prasac; 17-06-2010 at 01:16 AM.

#69

Very very nice work mate!!

Funny tough, we both have put fuel pump and alternator in EXACTLY the same position, albeit with a little different bracket solutions

Your welder is making pure fuckin' art btw

Funny tough, we both have put fuel pump and alternator in EXACTLY the same position, albeit with a little different bracket solutions

Your welder is making pure fuckin' art btw

Last edited by Zzz...Zzz; 17-06-2010 at 12:03 PM.

#70

yeah i just noticed that also

he does some great work, he has a very bright future ahead of him. we will be working together again on 2 more projects, im building a street/strip car at the end of the year. Australia is extremely strict when it comes to registering cars, we are only allowed 6-point roll cages and very minimal structural changes, we are hoping to run mid 7's and be a completely legal street car. if i was to build something like yours and be allowed to drive on Aussie roads i would be happy

#71

it's been a while since the last update. few small issues with the motor. align honing is the most difficult process with the modular engine and after the align hone it has been pulled apart and put together a few times and the clearances are not near enough to perfect so that has slowed the build down a bit, though it should all be sorted out next week. im hoping we have all the electricals and everything sorted in the next few weeks, i wanted to take it to Jambo but it looks like that may not be happening, i will more than likely have it ready by then but i won't have any time to test it, and it would be pointless taking an untested car to Jambo. at the moment looks like i will be out testing on September 4th @ WSID Test and Tune

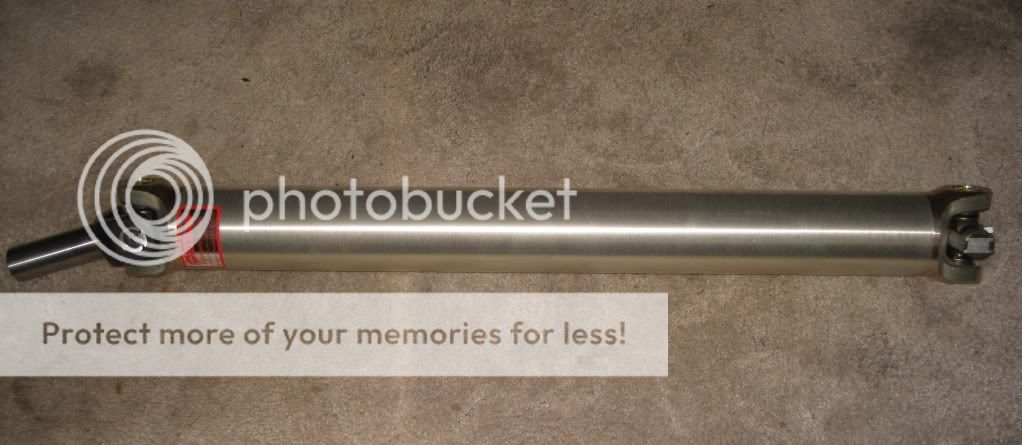

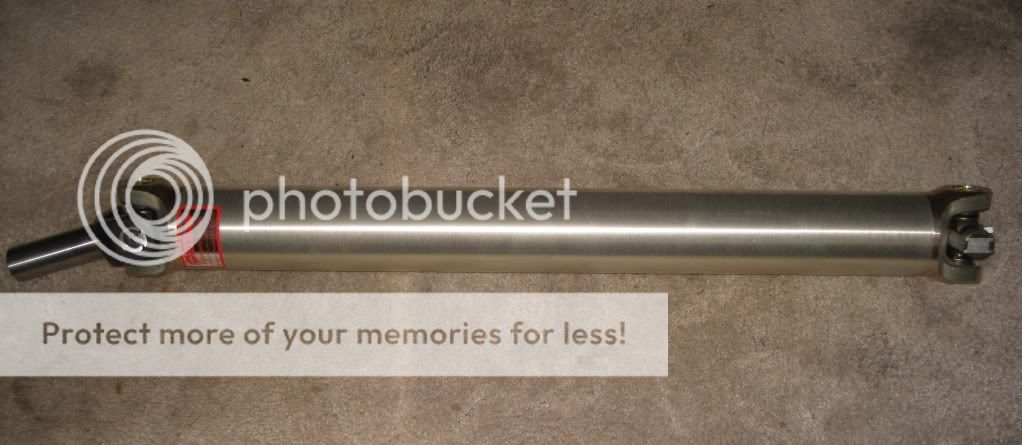

in the meantime i have some goodies slowly arriving, all my Mark Williams stuff is here and ready to be put together. after speaking with the guys at Mark Williams we decided to shift from a Carbon Fiber driveshaft as originally planned to a MW Duralcan MMC 3.5'' aluminium driveshaft, the ends are glued on using MW patented Accu-bond which has been SFI approved and as long as i don't produce 3 times the force a Pro-Stock car does i won't have a problem

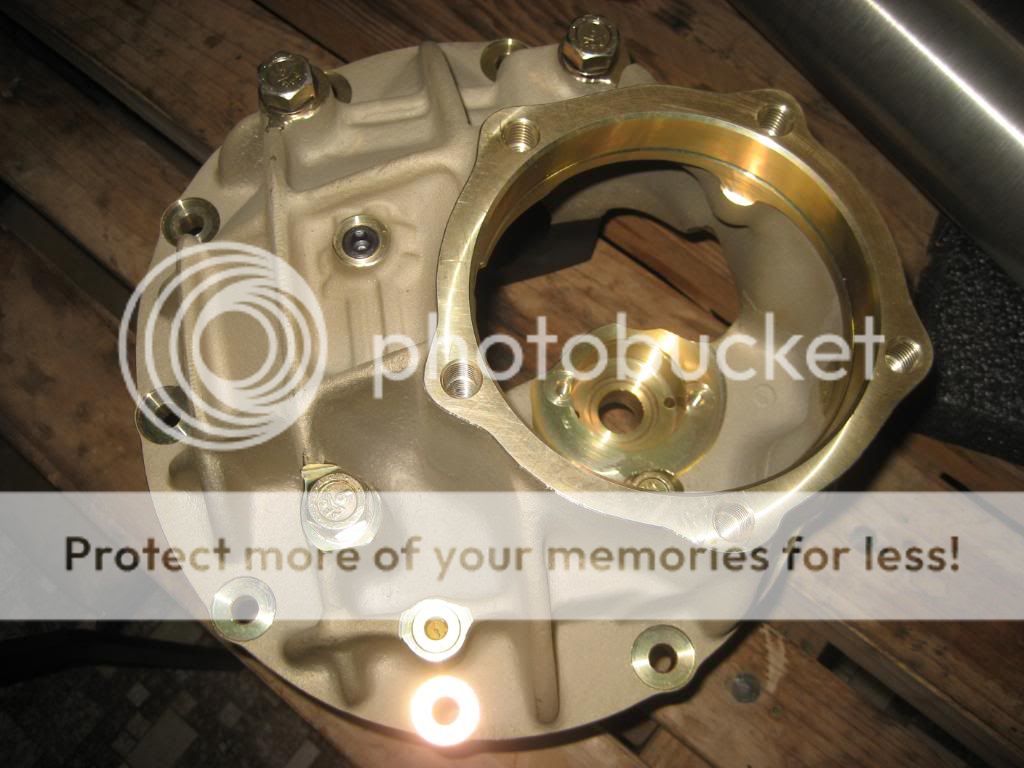

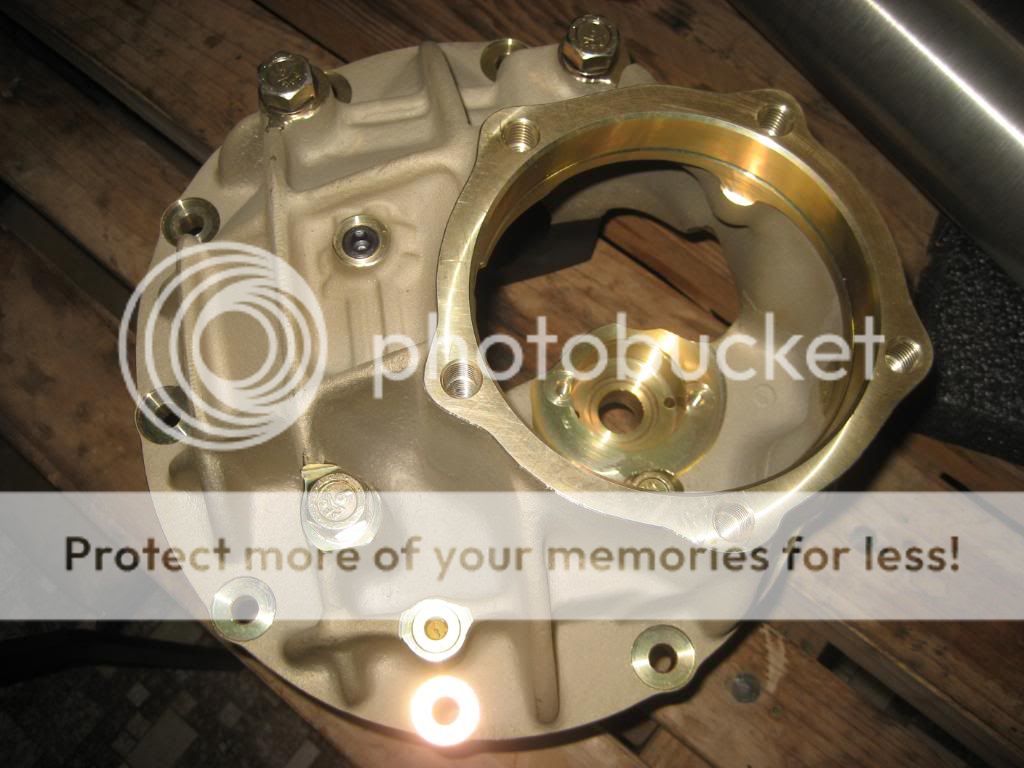

i went with a tough as you can get 9'' 3.812'' bore Aluminium thru bolt case with billet steel main caps, lightweight steel spool and 9.5'' gears. the 3.89 gear ratio we are running is good for 215mph @ 8500rpm. we haven't put the diff centre together yet as we have to check it will all fit in there with the bigger billet steel caps, but im confident it will.

in the meantime i have some goodies slowly arriving, all my Mark Williams stuff is here and ready to be put together. after speaking with the guys at Mark Williams we decided to shift from a Carbon Fiber driveshaft as originally planned to a MW Duralcan MMC 3.5'' aluminium driveshaft, the ends are glued on using MW patented Accu-bond which has been SFI approved and as long as i don't produce 3 times the force a Pro-Stock car does i won't have a problem

i went with a tough as you can get 9'' 3.812'' bore Aluminium thru bolt case with billet steel main caps, lightweight steel spool and 9.5'' gears. the 3.89 gear ratio we are running is good for 215mph @ 8500rpm. we haven't put the diff centre together yet as we have to check it will all fit in there with the bigger billet steel caps, but im confident it will.

#72

small update, diff centre has been put together and is good to go. has been made pretty hardcore, more than enough to support the 1700hp of this engine and 2500hp of the new engine. 9.5'' diff gear with 3.89 ratio (8300rpm, 215mph, 33'' slick) went with 9.5'' gears as they are much tougher and can take more of a beating than the 9'' gears, so should see alot more passes before having to change them out.

#78

has the rear diff got no planet gears ? as in fixed drive both wheels turn together

has the rear diff got no planet gears ? as in fixed drive both wheels turn together