JWRC Mid-engined RWD Puma, Mk1 Focus RS Engine

#41

Boooost!

Thread Starter

So I've got some photos that Dave took when he started but photobucket has screwed me over as well as most others by the looks of it.

Should have some more photos coming this week which should show good progress and a lot more coming together that's if I can find a decent way of hosting photos now

that's if I can find a decent way of hosting photos now

Should have some more photos coming this week which should show good progress and a lot more coming together

#44

Boooost!

Thread Starter

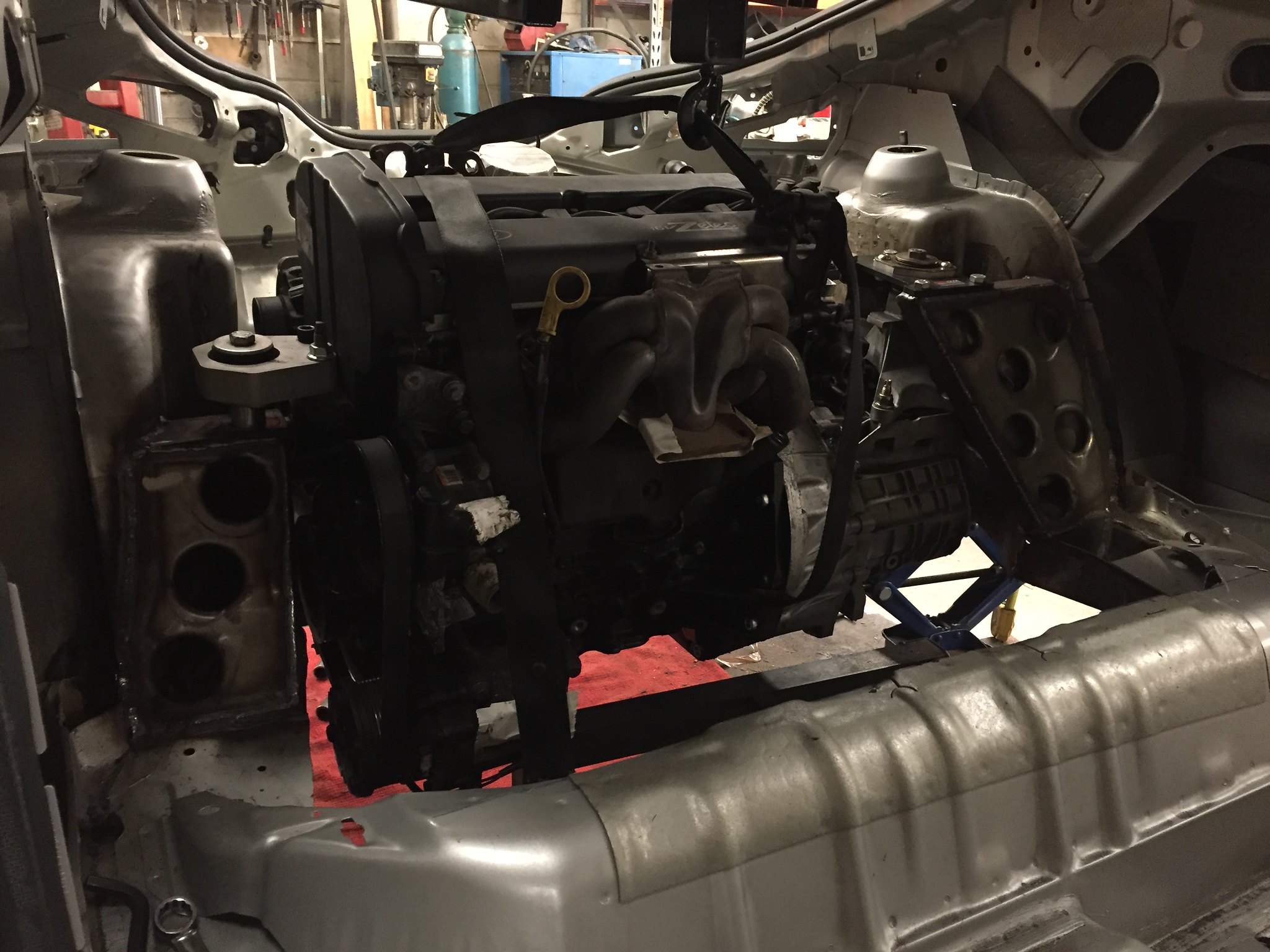

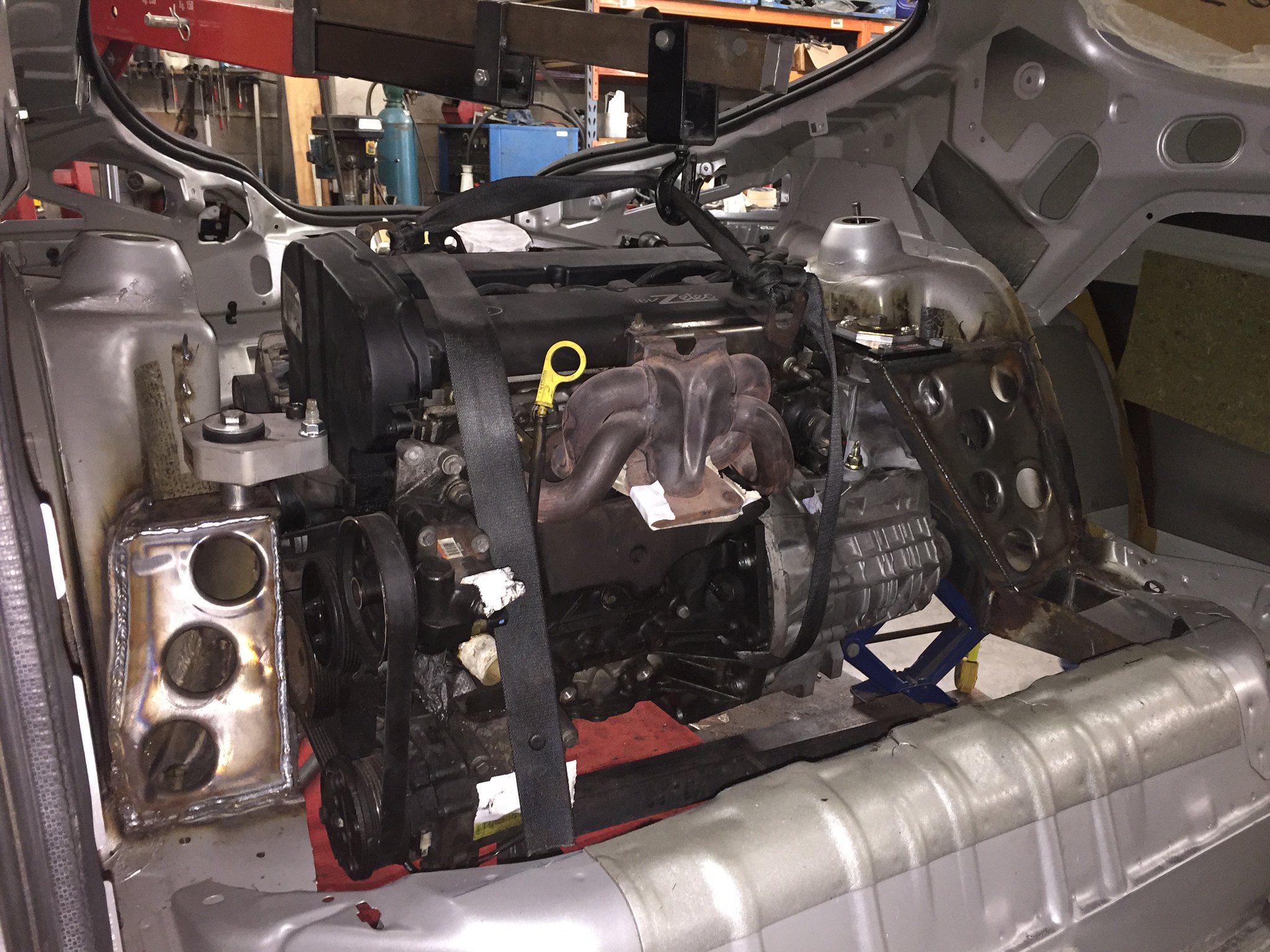

This time, with the new shell and engine position I went with the standard engine and gearbox mounts rather than custom which I had before with the engine in the front.

Obviously Dave has done the fabrication work to allow the use of these as you can see.

There's work of the subframe also, of which Dave decided to use the Mk1 Focus subframe as this seemed the best way to get the wishbone/lower arm mounting points in the best position.

The plan is to use FRS hubs, driveshafts and FRS/Mk1 Focus fitment shocks. We will get some toe in/out adjustment from new rods that will mount to the subframe.

Obviously Dave has done the fabrication work to allow the use of these as you can see.

There's work of the subframe also, of which Dave decided to use the Mk1 Focus subframe as this seemed the best way to get the wishbone/lower arm mounting points in the best position.

The plan is to use FRS hubs, driveshafts and FRS/Mk1 Focus fitment shocks. We will get some toe in/out adjustment from new rods that will mount to the subframe.

#48

Boooost!

Thread Starter

Thanks, will be good to see it together with hubs, uprights, shafts etc.

Front end will need adapting to suit the new setup once the rear end is done too.

Front end will need adapting to suit the new setup once the rear end is done too.

#51

Boooost!

Thread Starter

Got, hopefully, what will be a decent update with plenty of photos. Not sure there's really much to say..

These RS hubs and focus arms are going to need some prep and paint I feel. New chassis rail looking beefy though.

From the boot

Better photo from the front

Some new wheel tubs! I think it's fair to say these are pretty epic..

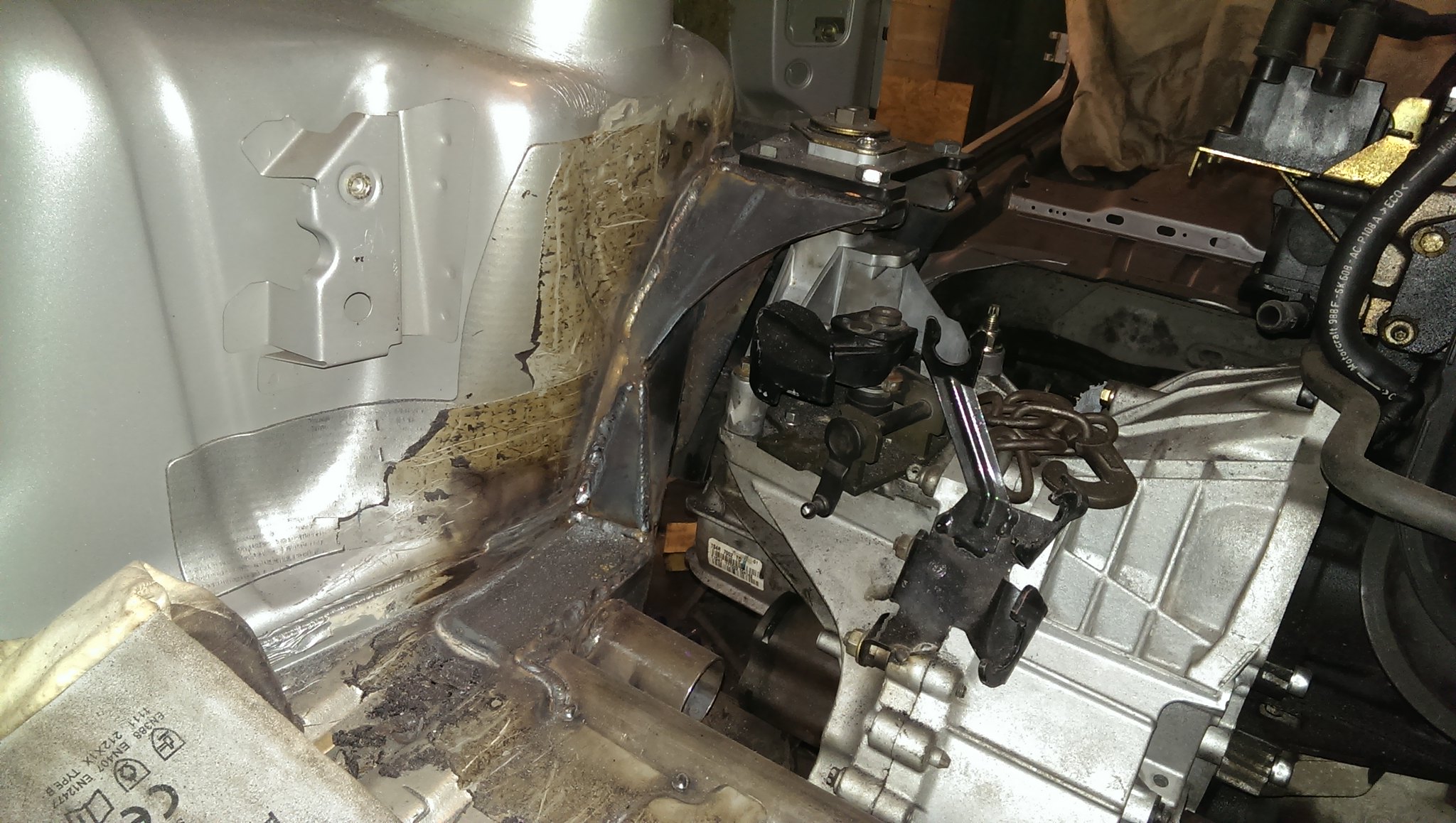

More of the gearbox mount

Work on the focus subframe

I'm really pleased with how it's coming along, and that I decided not to tackle this job myself - there's a bit more to it than I thought!

These RS hubs and focus arms are going to need some prep and paint I feel. New chassis rail looking beefy though.

From the boot

Better photo from the front

Some new wheel tubs! I think it's fair to say these are pretty epic..

More of the gearbox mount

Work on the focus subframe

I'm really pleased with how it's coming along, and that I decided not to tackle this job myself - there's a bit more to it than I thought!

Last edited by moondustka; 16-09-2017 at 01:34 PM.

#52

Advanced PassionFord User

And I thought some work had gone into mine! Nice update. I hope you're getting some overtime in.

#54

Advanced PassionFord User

Glad to see its still progressing.

I'm still thinking about a rear engine conversion on a car, I have the choice of using a car that was originally made in both FWD and AWD versions, i'm leaning towards getting a AWD one and using the current rear subframe as i'd be able to use how it is to mount the gearbox mounts easily then have the engine mounted to the body with support to it and a roll cage. I have the engine just waiting for the right car to turn up now.

How are you planning on getting the gear linkage to work? Thats one of my concerns with what i'm thinking. I have been looking at a 944 setup for mine but the issue is unlike the 944 setup i'd have the engine in the way

I'm still thinking about a rear engine conversion on a car, I have the choice of using a car that was originally made in both FWD and AWD versions, i'm leaning towards getting a AWD one and using the current rear subframe as i'd be able to use how it is to mount the gearbox mounts easily then have the engine mounted to the body with support to it and a roll cage. I have the engine just waiting for the right car to turn up now.

How are you planning on getting the gear linkage to work? Thats one of my concerns with what i'm thinking. I have been looking at a 944 setup for mine but the issue is unlike the 944 setup i'd have the engine in the way

#55

Boooost!

Thread Starter

If you have the choice of a using a car that's already available in AWD, I would just keep it AWD. Unfortunately the Puma and all the smaller Fords are only available as FWD, so hence all this effort.

Some would say, just go buy something else, but I feel this just something a bit different and being different is what I like.

Dave is sorting me some longer cables, I need to talk to him about the actual gearstick and throw direction for operating the cables.. It would actually be easier to go paddle shift but that's waaayyy too much money.

So you're looking at a 944?

Some would say, just go buy something else, but I feel this just something a bit different and being different is what I like.

Dave is sorting me some longer cables, I need to talk to him about the actual gearstick and throw direction for operating the cables.. It would actually be easier to go paddle shift but that's waaayyy too much money.

So you're looking at a 944?

#56

Boooost!

Thread Starter

Got another update..

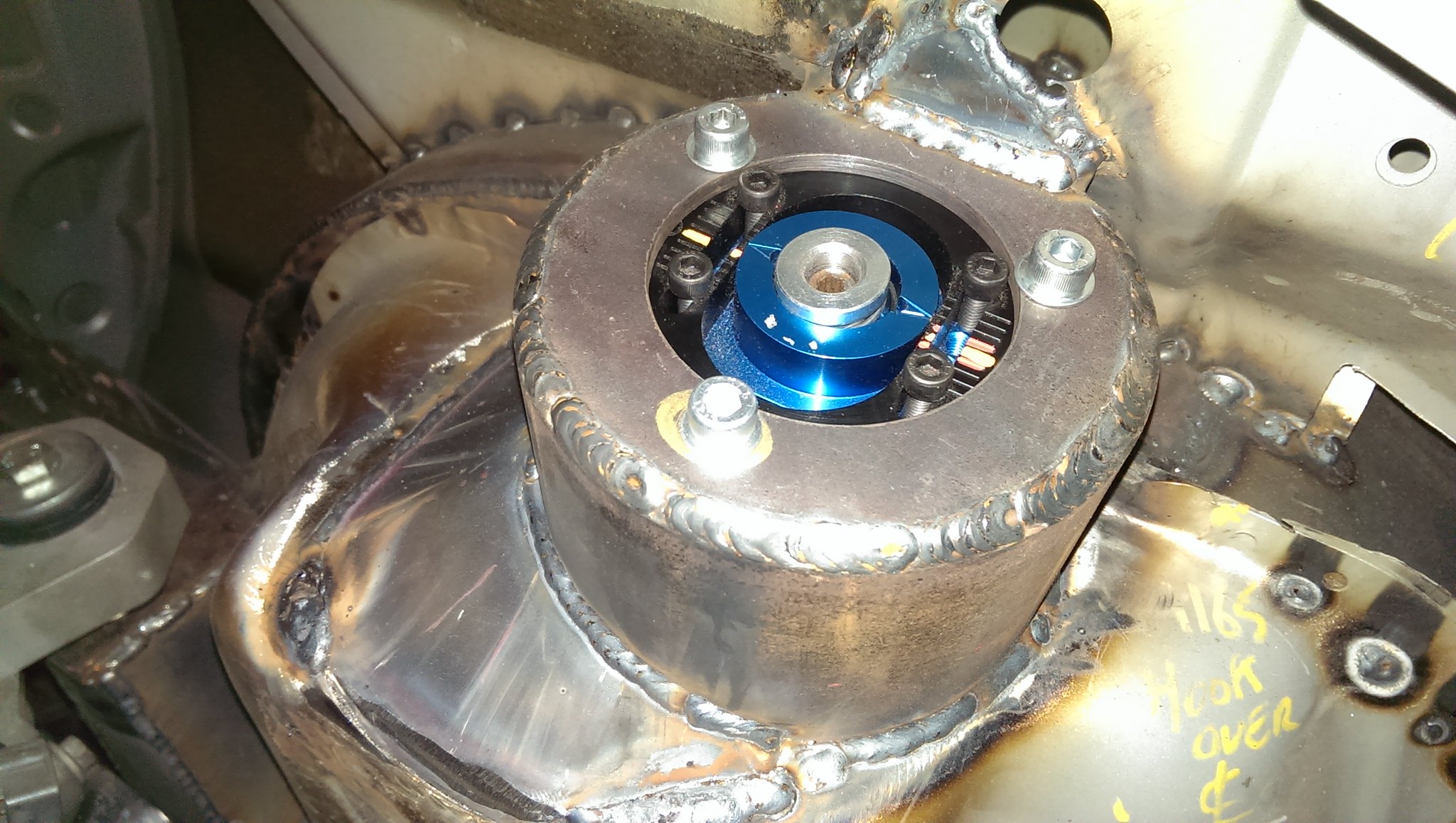

New suspension turrets with adjustable top mounts have now been done.

They need some sleeve nuts to fix them though I think, there is just a spacer (comes with the adjustable mounts) resting there in these photos.

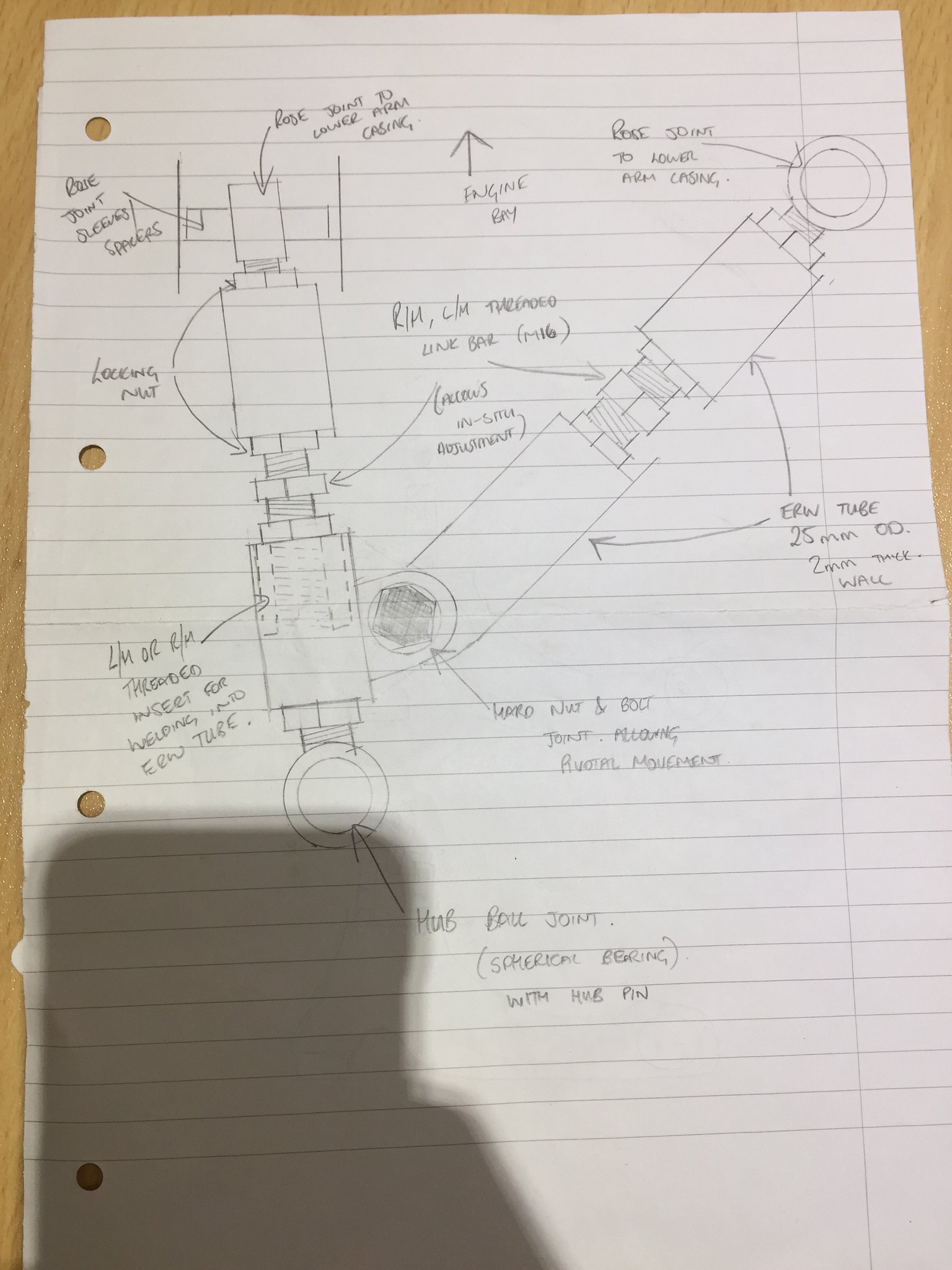

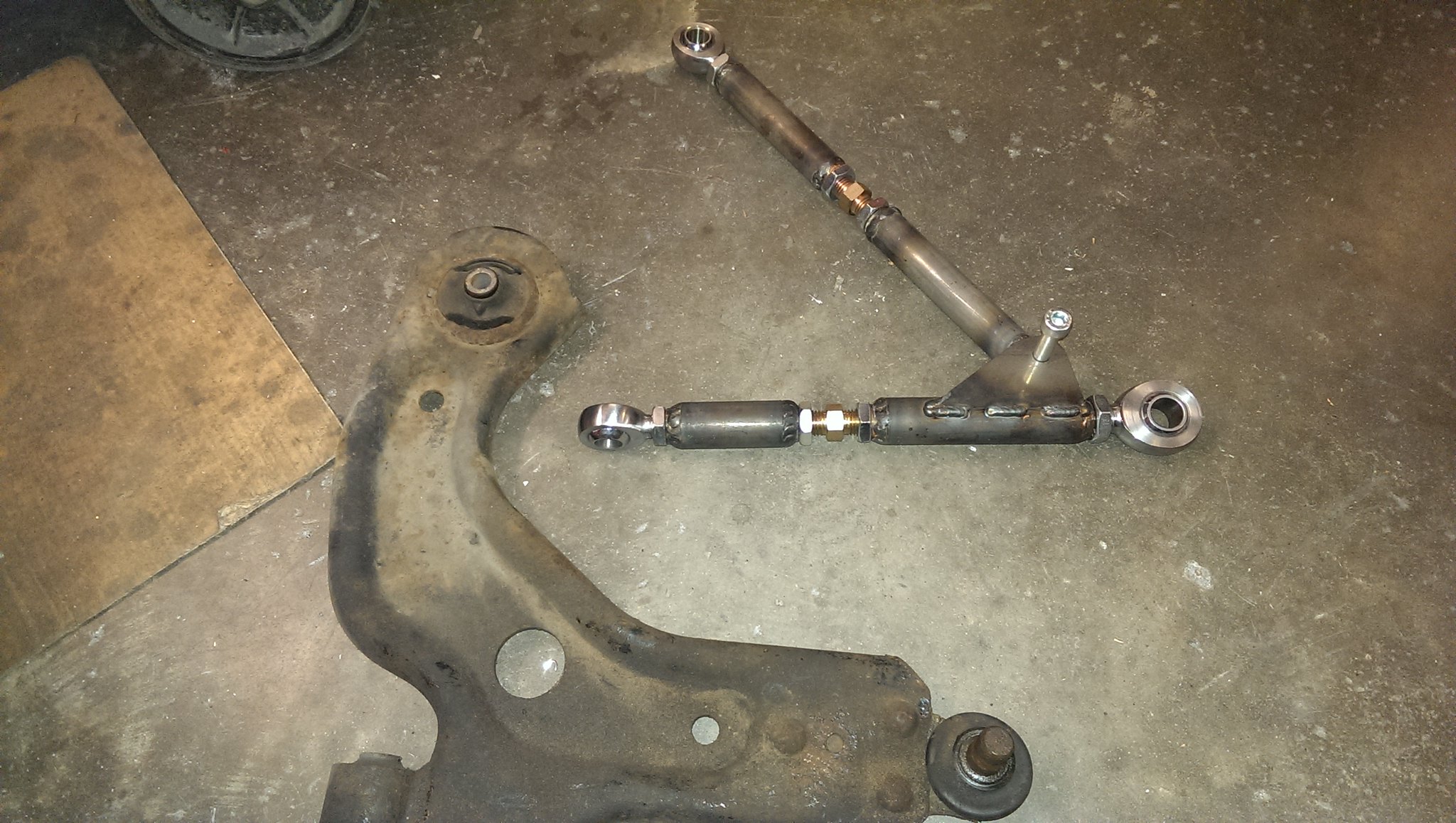

About 3 years ago now, I drew this on holiday (sad, I know).. I then bought all the bits 6 months later and then never got around to making them because I realised the turning circle would be shocking, the rear tube needed to be bent and then I couldn't make up my mind on what tube I needed as I knew what I've put on on the drawing would not be sufficient.

Anyway, I then spoke to Dave about my 'idea' and he said to send up what I've got. I said, you've probably got a better solution, but then he sent me these photos:

Said it was a decent design, he specced different tube as I'd already thought and made them. They are 30mm wider than standard to take into account the need for larger track width.

He said they would need to be made stronger for driven wheels but for this application they'll be fine, as there is a lot less weight and load on them. Apparently also the reason rose joints will be ok and won't become rattly because there's a lot less load than on a driven axle. Also why he's stayed away from a rose jointed arm at the rear, because it's going to be a road car, firstly, so polybushes will feel nicer and be quiet.

No photos of adjustment to front subframe yet (to take out the anti-dive).

Dave is aiming for end of the month for me to pick it up

New suspension turrets with adjustable top mounts have now been done.

They need some sleeve nuts to fix them though I think, there is just a spacer (comes with the adjustable mounts) resting there in these photos.

About 3 years ago now, I drew this on holiday (sad, I know).. I then bought all the bits 6 months later and then never got around to making them because I realised the turning circle would be shocking, the rear tube needed to be bent and then I couldn't make up my mind on what tube I needed as I knew what I've put on on the drawing would not be sufficient.

Anyway, I then spoke to Dave about my 'idea' and he said to send up what I've got. I said, you've probably got a better solution, but then he sent me these photos:

Said it was a decent design, he specced different tube as I'd already thought and made them. They are 30mm wider than standard to take into account the need for larger track width.

He said they would need to be made stronger for driven wheels but for this application they'll be fine, as there is a lot less weight and load on them. Apparently also the reason rose joints will be ok and won't become rattly because there's a lot less load than on a driven axle. Also why he's stayed away from a rose jointed arm at the rear, because it's going to be a road car, firstly, so polybushes will feel nicer and be quiet.

No photos of adjustment to front subframe yet (to take out the anti-dive).

Dave is aiming for end of the month for me to pick it up

#57

10K+ Poster!!

Lovely build, keeping an eye on this one

The following users liked this post:

moondustka (07-10-2017)

#58

Advanced PassionFord User

Nice update Ben. What's with the pictures they keep crashing my iPad when I view them. Is it just me?

#59

Boooost!

Thread Starter

#60

Boooost!

Thread Starter

Next bit...

Adaptions top the front subframe. This raises the front mounting point of the lower arm.

And new, but fixed top mounts. These have been moved to accommodate geo and wider track.

Adaptions top the front subframe. This raises the front mounting point of the lower arm.

And new, but fixed top mounts. These have been moved to accommodate geo and wider track.

#62

10K+ Poster!!

This is a noob question: When you do a seam weld, like on the front sub frame how does this sit with the MOT testers where they say the welds must always be continuous? Is it due to one being a repair to the body and the other being a structural modification?

#63

Boooost!

Thread Starter

I know what you mean about the adjustment. I did ask Dave, he said because there’s little weight on the front there won’t much load through it. I designed it this way to get camber and caster adjustment in the same arm as top mounts are fixed.

Well done on your career change and new job by the way!

The following users liked this post:

M K (22-11-2017)

#64

Boooost!

Thread Starter

I’ve no idea, Toby. Didn’t even know it had to be continuous. I thought a seam weld was continuous? Stitch welding is the other one? Where the welds are for an inch then miss a bit then an inch etc.

#66

10K+ Poster!!

So same question then with stitch weld?

#67

Boooost!

Thread Starter

Stitch welding is usually what you can do to a shell to make it stiffer rather than relying on the spot welds on the panel joins. For example there is a Ford plan (I think I am remembering correctly) for the escort series 1 which gives you all the stitch weld locations.

No idea though how modifying structural points of the car fares in an MOT.

We are fortunate in this country that we can make our engine mounts etc without having to obtain an engineers certificate for them like the Germans and Spanish seem to have to do.

I do know though that whatever Dave does to the car, it will be more than strong enough

No idea though how modifying structural points of the car fares in an MOT.

We are fortunate in this country that we can make our engine mounts etc without having to obtain an engineers certificate for them like the Germans and Spanish seem to have to do.

I do know though that whatever Dave does to the car, it will be more than strong enough

#68

10K+ Poster!!

Stitch welding is usually what you can do to a shell to make it stiffer rather than relying on the spot welds on the panel joins. For example there is a Ford plan (I think I am remembering correctly) for the escort series 1 which gives you all the stitch weld locations.

No idea though how modifying structural points of the car fares in an MOT.

We are fortunate in this country that we can make our engine mounts etc without having to obtain an engineers certificate for them like the Germans and Spanish seem to have to do.

I do know though that whatever Dave does to the car, it will be more than strong enough

No idea though how modifying structural points of the car fares in an MOT.

We are fortunate in this country that we can make our engine mounts etc without having to obtain an engineers certificate for them like the Germans and Spanish seem to have to do.

I do know though that whatever Dave does to the car, it will be more than strong enough

The following users liked this post:

ted11 (08-12-2017)

Thread

Thread Starter

Forum

Replies

Last Post

JoeyBoyden

General Car Related Discussion.

4

12-09-2016 12:18 PM