Dutch Sierra Cosworth 4x4 - home made power measurement

#161

Too many posts.. I need a life!!

Awesome read Marc. Some very very good information in this thread!

Funny Caddy how you say you dont care about the science behind it, when that is what make the car go fast around corners. Having an understanding of it helps make decisions on what to improve, and how to design parts that actually improves things.

What would be the solution to getting the car handle the best way possible Marc? Front&Rear.

Funny Caddy how you say you dont care about the science behind it, when that is what make the car go fast around corners. Having an understanding of it helps make decisions on what to improve, and how to design parts that actually improves things.

What would be the solution to getting the car handle the best way possible Marc? Front&Rear.

Last edited by nixon_2wd; 02-03-2018 at 09:12 AM.

#162

10K+ Poster!!

Awesome read Marc. Some very very good information in this thread!

Funny Caddy how you say you dont care about the science behind it, when that is what make the car go fast around corners. Having an understanding of it helps make decisions on what to improve, and how to design parts that actually improves things.

What would be the solution to getting the car handle the best way possible Marc? Front&Rear.

Funny Caddy how you say you dont care about the science behind it, when that is what make the car go fast around corners. Having an understanding of it helps make decisions on what to improve, and how to design parts that actually improves things.

What would be the solution to getting the car handle the best way possible Marc? Front&Rear.

I TOTALLY agree that understanding the science improves beyond anything else and motor racing has shown that the driver who can explain to and understand how to talk to his mechanics will likely be the person to win or progress with a team.

When Trevor Reeves used to drive my cars on track he could immediately tell me if I needed to adjust suspension or tyre pressures etc.

#163

10K+ Poster!!

The rear WRC cradle will be moved up about 1 inch in to the boot floor from the normal WRC escort starting point. All 4 shox will be equal length as they are all front ones in reality (i.e. front being used on the rear too)

#164

Awesome read Marc. Some very very good information in this thread!

Funny Caddy how you say you dont care about the science behind it, when that is what make the car go fast around corners. Having an understanding of it helps make decisions on what to improve, and how to design parts that actually improves things.

What would be the solution to getting the car handle the best way possible Marc? Front&Rear.

Funny Caddy how you say you dont care about the science behind it, when that is what make the car go fast around corners. Having an understanding of it helps make decisions on what to improve, and how to design parts that actually improves things.

What would be the solution to getting the car handle the best way possible Marc? Front&Rear.

Thanks!! I'm trying to understand what influences the handling of a car, but the more you read about it the more questions come up.

I was reading more on the roll centres and how they move during cornering. Apparently they don't only move up and down, but also sideways. That is because the roll centres is not the intersection of the line from the tyre patch to the instant centre with the centre of the car, but it is the intersection of the lines from both tyre patches to both instant centres. In a stationary situation everything is symmetrical, so it is in the centre of the car. But during cornering both instant centres move and it becomes quite complicated where the roll centre ends up.

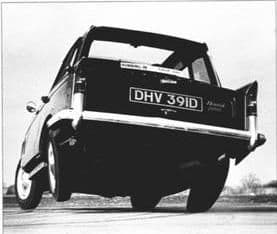

What also happens with a high roll centre is that you get 'jacking forces' that push the car up. What basically happens is that the forces go through the suspension arms instead of the springs and the suspension arms push the car up. This can be seen very well on a swing arm suspension like this:

Anyway, on the question what will make the car handle best. There are lots of opinions on this in general. But mine is to have the thickest anti-roll bars as possible, with stiff bushes to be able to run as soft springs as possible. On the front I think the TCAs should be in such a way that they go slightly down from the cross member towards the knuckles. That way the position of the front roll centre shouldn't move too much during cornering.

For the rear the 6 degree beam is good, and I guess it would be best combined with solid beam mounts to make sure the toe doesn't change by the beam moving around underneath the car. Also the ride height on the rear shouldn't be too low because that increases the squat from the rear during acceleration. And if the rear is low the camber and toe will also change faster than at a higher ride height.

For the springs it's best to not run a very stiff spring as a softer spring provides more grip. The only downside of the softer springs is that you get more body roll and the camber angles will be less good. On a track that is very smooth that will be fine, but on a bumpy road you want the softer springs to keep the wheels better on the ground. So in the end it's all a compromise and really depends what you want from the car.

I'm definately not an expert on chassis dynamics and I also have not tested much on these things, so everything is based on my (limited) knowledge and experience. But everything can always be better, just look at the development on F1 cars.

#165

10K+ Poster!!

I agree, I would have stiff on the anti roll bar and soft on the springs and then let a quality damper do the work. So many coilovers etc have stiff springs to hide the rubbish shock absorber.

I actually prefer the car to roll and move a little bit and feel the weight transfer as the car is less edgy and more forgiving and predictable.

I actually prefer the car to roll and move a little bit and feel the weight transfer as the car is less edgy and more forgiving and predictable.

#166

Too many posts.. I need a life!!

We found that on our FSAE car, the suspension geometry affects handling pretty much like you are describing Marc. By having the roll center closer to the center of gravity we could reduce spring rates and have a much more controllable car. By letting the dampers do their job - which is to dampen uneven track (up and down), and not compensate for body roll. Let the suspension arms take the lateral forces.

As you are saying Marc, and you Caddy briefly mention, when lowering a saph the control arms make the roll center go below ground and adds massive body roll which then needs to be compensated for with stiff ARBs and high spring rates.

This is the first time Ive seen the actual figures for the "stock suspension" Sapphire, so massive creds to you for taking the time Marc.

A WRC tarmac setup will pretty much do what you want.

As you are saying Marc, and you Caddy briefly mention, when lowering a saph the control arms make the roll center go below ground and adds massive body roll which then needs to be compensated for with stiff ARBs and high spring rates.

This is the first time Ive seen the actual figures for the "stock suspension" Sapphire, so massive creds to you for taking the time Marc.

A WRC tarmac setup will pretty much do what you want.

Last edited by nixon_2wd; 02-03-2018 at 07:02 PM.

#168

10K+ Poster!!

I think it is a formula student race car

#169

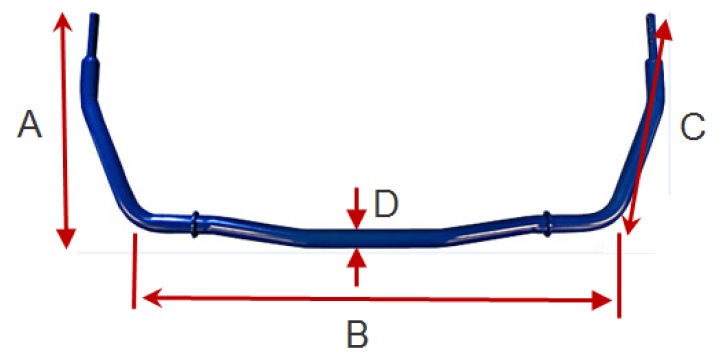

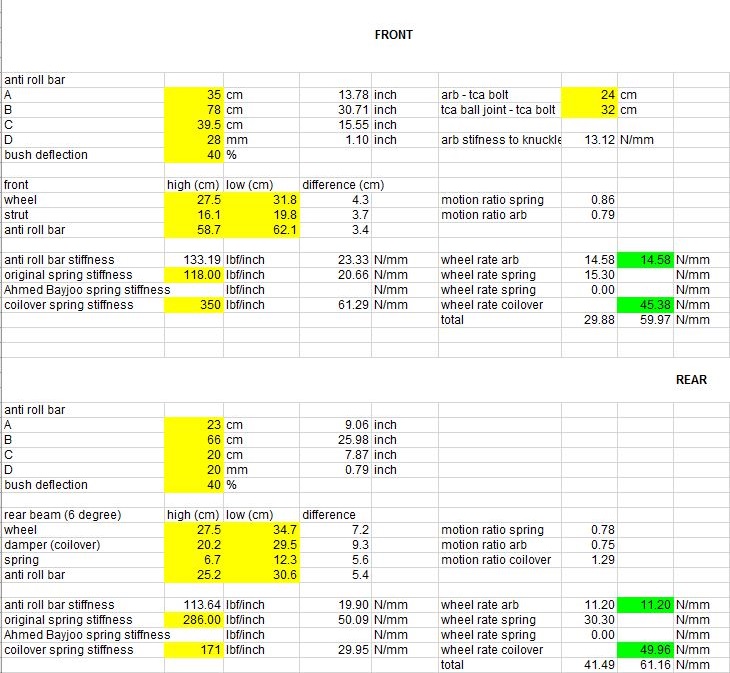

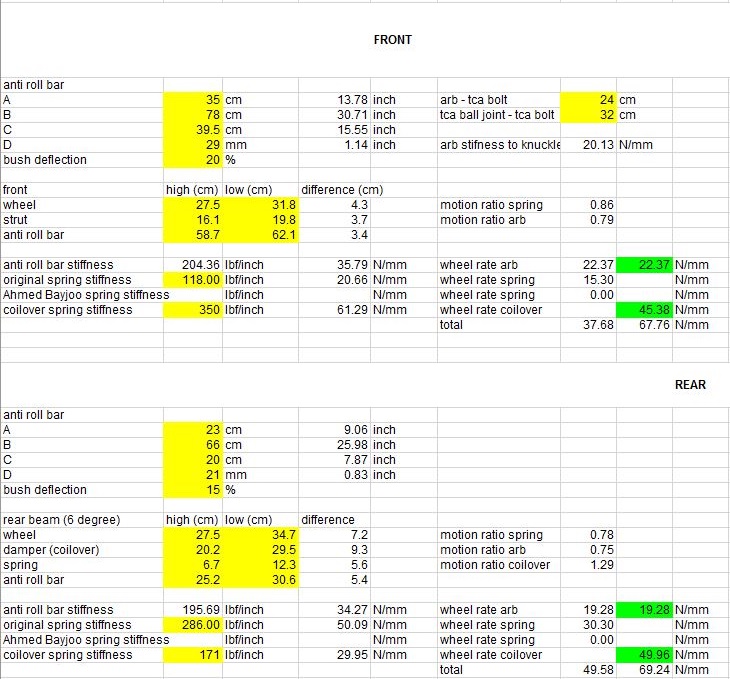

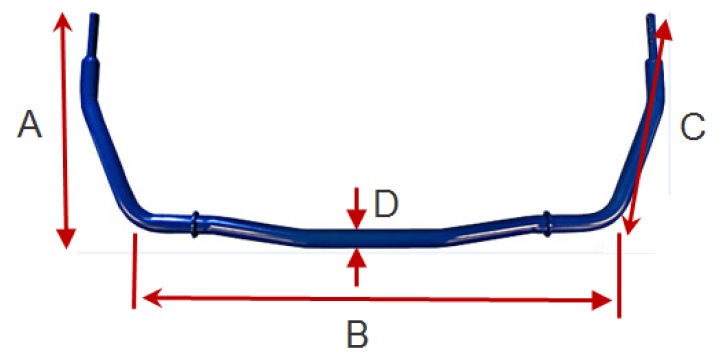

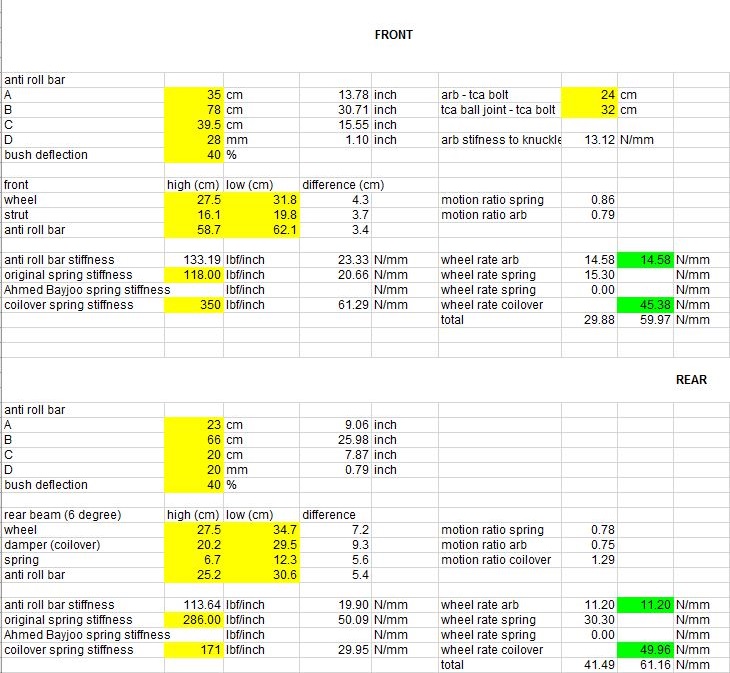

Something I have also been wondering about is whether the stiffness of the anti roll bars are really significant compared to the stiffness of the springs. Some people remove the front ani roll bar in order to fit compression struts. I wouldn't think that would be a good idea, but I could never put any numbers to it.

But now I found a formula to rougly calculate the spring rate of an anti roll bar:

So I measured the A, B, C and D dimensions for the front and rear anti roll bars and put them into Excel again to calculate the spring rates.

The spring rates themselves cannot be compared directly to the spring rates of the coil springs because the arbs are mounted in bushes and are acting at different positions on the suspension arms then the coil springs. So I multiplied the arb stiffness with a percentage for the deflection of the arb rubbers/bushes. The less the bushes deflect the better the arb will work.

And to be able to compare the arb spring rates with the coil spring spring rates I measured the motion ratios for both the arb and the coil springs. If you convert the spring rate with the motion ratio you get the wheel rate, which is really the spring stiffness as seen at the wheel.

I converted all the spring rates from lbf/inch to N/mm because I don't really like the imperical system.

For the 28 mm thick front arb I used a bush deflection of 40% for the standard bushes, which gives a wheel rate of 14.58 N/mm. The original front springs on a sapph are 118 lbf/inch which give a wheel rate of 15.3 N/mm. So it seems like the arb and coil spring are just about as stiff originally. But that isn't actually true. Because when the arb moves up on the outer wheel during cornering it moves down by the same amount on the inner wheel. So that means you have twice as much travel on the arb, which means the force is also twice as much. So you should actually compare 29.2 N/mm for the arb with 15.3 N/mm for the coil spring. So on a standard car the arb is doing double the work of the coil spring in keeping the car level during cornering.

With typical coilovers springs of 350 lbf/inch the springs are about 3 times as stiff as original. So in that case the springs are doing more than the arb, but not by a huge amount. My car is still on the Ahmed Bayjoo springs, but according to Mike Rainbird those spring rates are close to the coilover spring rates I used here.

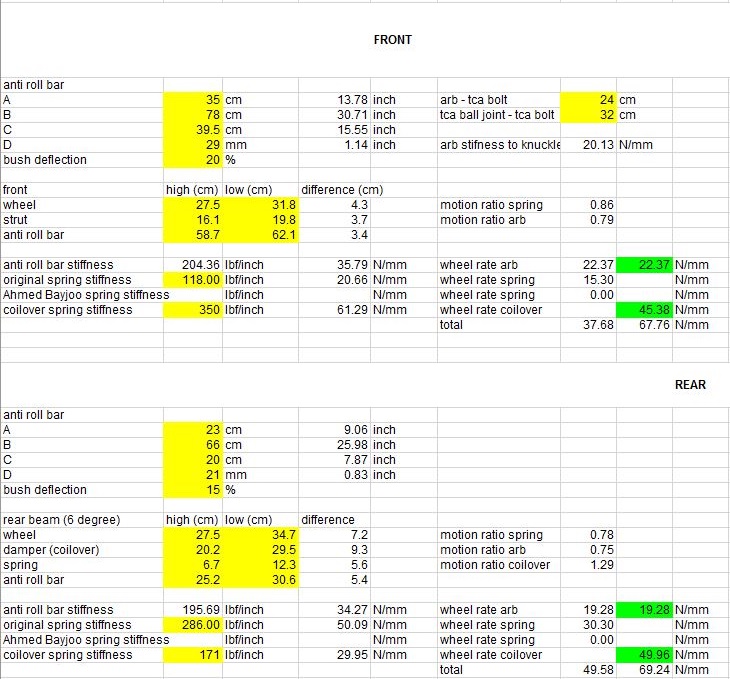

Last year I swapped the 28 mm Sapph 4x4 front arb for a 29 mm arb off an Escort Cosworth. Together with that I fitted some purple Powerflex arb to chassis bushes and black Powerflex arb to tca bushes. With those changes I estimated the bush deflection to 20%. This now gives the arb a wheel rate of 22.37 N/mm, which means it should now be about as stiff as the Ahmed Bayjoo springs.

Maybe this can be of some use to someone.

But now I found a formula to rougly calculate the spring rate of an anti roll bar:

So I measured the A, B, C and D dimensions for the front and rear anti roll bars and put them into Excel again to calculate the spring rates.

The spring rates themselves cannot be compared directly to the spring rates of the coil springs because the arbs are mounted in bushes and are acting at different positions on the suspension arms then the coil springs. So I multiplied the arb stiffness with a percentage for the deflection of the arb rubbers/bushes. The less the bushes deflect the better the arb will work.

And to be able to compare the arb spring rates with the coil spring spring rates I measured the motion ratios for both the arb and the coil springs. If you convert the spring rate with the motion ratio you get the wheel rate, which is really the spring stiffness as seen at the wheel.

I converted all the spring rates from lbf/inch to N/mm because I don't really like the imperical system.

For the 28 mm thick front arb I used a bush deflection of 40% for the standard bushes, which gives a wheel rate of 14.58 N/mm. The original front springs on a sapph are 118 lbf/inch which give a wheel rate of 15.3 N/mm. So it seems like the arb and coil spring are just about as stiff originally. But that isn't actually true. Because when the arb moves up on the outer wheel during cornering it moves down by the same amount on the inner wheel. So that means you have twice as much travel on the arb, which means the force is also twice as much. So you should actually compare 29.2 N/mm for the arb with 15.3 N/mm for the coil spring. So on a standard car the arb is doing double the work of the coil spring in keeping the car level during cornering.

With typical coilovers springs of 350 lbf/inch the springs are about 3 times as stiff as original. So in that case the springs are doing more than the arb, but not by a huge amount. My car is still on the Ahmed Bayjoo springs, but according to Mike Rainbird those spring rates are close to the coilover spring rates I used here.

Last year I swapped the 28 mm Sapph 4x4 front arb for a 29 mm arb off an Escort Cosworth. Together with that I fitted some purple Powerflex arb to chassis bushes and black Powerflex arb to tca bushes. With those changes I estimated the bush deflection to 20%. This now gives the arb a wheel rate of 22.37 N/mm, which means it should now be about as stiff as the Ahmed Bayjoo springs.

Maybe this can be of some use to someone.

#170

I already received my new TCAs last year but still hadn't fitted them yet. But now I thought it was time to finally fit them. I quickly ran into the first 'problem'. Under full droop the ball joint turns quite far inwards, which causes the knuckle to very close to the eye in the TCA where the ARB is fitted. If the steering is then turned the head of the pinch bolt in the knuckle slightly touched the TCA.

It touched the TCA at the thicker edge from the casting. Likely that could easily be filed down a bit, after which there is just enough room. In practice it wouldn't really be a problem, because it only happened on full droop with a lot of steering angle.

With a standard TCA next to it you can see the additional length on the ball joint pin.

After fitting the TCAs I also needed to fit the new tie rod ends. There I ran into the next problem. The new tie rod ends are longer than the standard items, which meant the tie rods were too long. I could have cut them, but then there was not enough thread on the tie rod to put the tie rod end on. After searching for a solution I found that some regular 2wd tie rods I had lying around were actually shorter than the 4x4 ones. They were still a bit too long, but at least they had enough thread left after cutting them to length.

Unfortunately I still couldn't fit the tie rod ends. At full droop the angle on the tie rod ends was too big for the rose joints. So I changed the rose joints from 1/2" hole to a 5/8" hole and used some high misalignment spacers to make the angle on the rose joint bigger. In order to fit the spacers I had the pins turned down on a lathe by a local company. But after this everything finally fitted.

After fitting everything I checked in a simple, not super accurate way how much spacers were needed on the steering pins to get no bumpsteer. In the last picture the tie rod was mounted in the highest position, which seemed to give no bumpsteer. This still needs to be checked more accurately when doing the wheel alignment.

It touched the TCA at the thicker edge from the casting. Likely that could easily be filed down a bit, after which there is just enough room. In practice it wouldn't really be a problem, because it only happened on full droop with a lot of steering angle.

With a standard TCA next to it you can see the additional length on the ball joint pin.

After fitting the TCAs I also needed to fit the new tie rod ends. There I ran into the next problem. The new tie rod ends are longer than the standard items, which meant the tie rods were too long. I could have cut them, but then there was not enough thread on the tie rod to put the tie rod end on. After searching for a solution I found that some regular 2wd tie rods I had lying around were actually shorter than the 4x4 ones. They were still a bit too long, but at least they had enough thread left after cutting them to length.

Unfortunately I still couldn't fit the tie rod ends. At full droop the angle on the tie rod ends was too big for the rose joints. So I changed the rose joints from 1/2" hole to a 5/8" hole and used some high misalignment spacers to make the angle on the rose joint bigger. In order to fit the spacers I had the pins turned down on a lathe by a local company. But after this everything finally fitted.

After fitting everything I checked in a simple, not super accurate way how much spacers were needed on the steering pins to get no bumpsteer. In the last picture the tie rod was mounted in the highest position, which seemed to give no bumpsteer. This still needs to be checked more accurately when doing the wheel alignment.

Last edited by Marc sierra; 13-07-2018 at 10:30 AM.

The following users liked this post:

jsa (13-07-2018)

#171

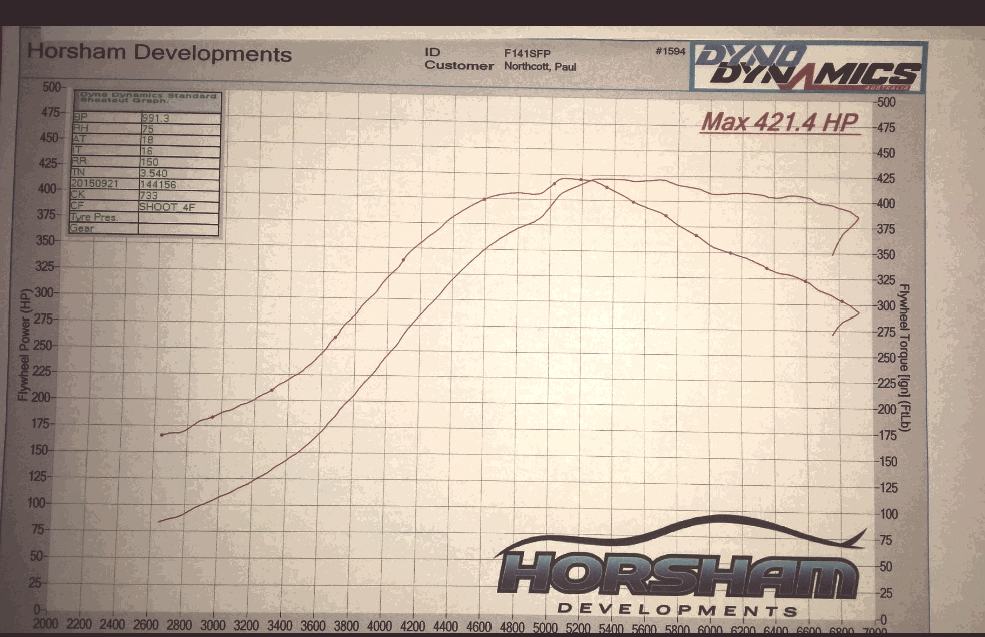

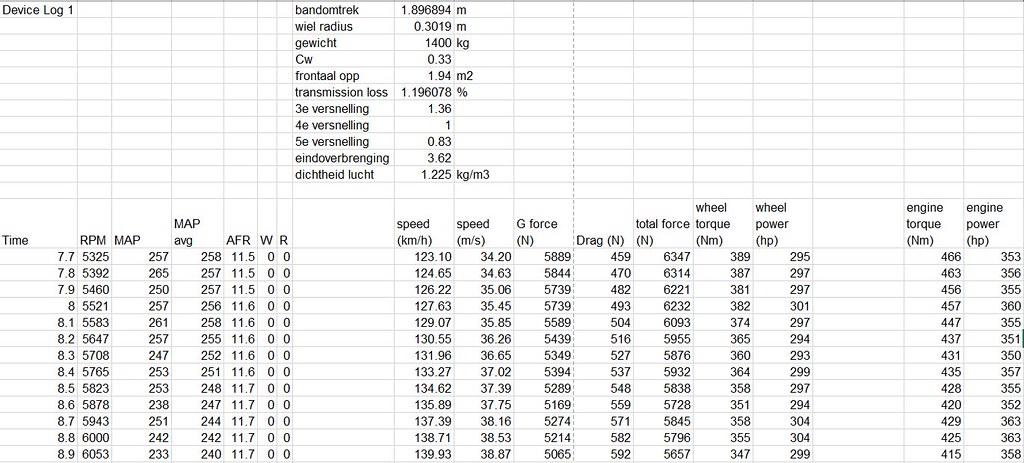

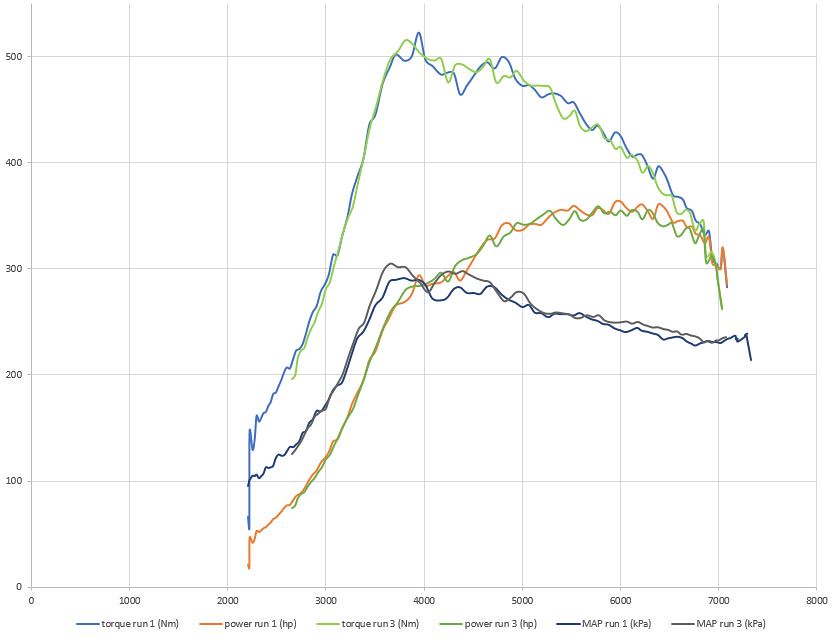

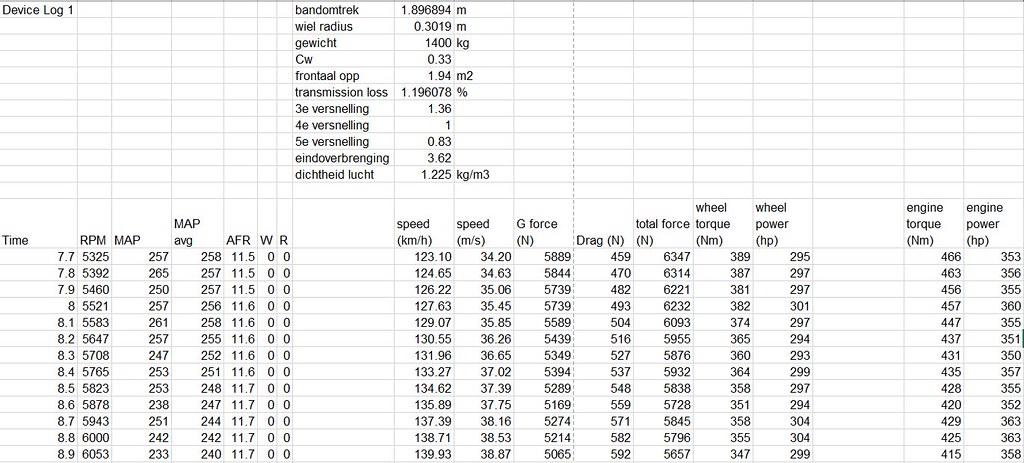

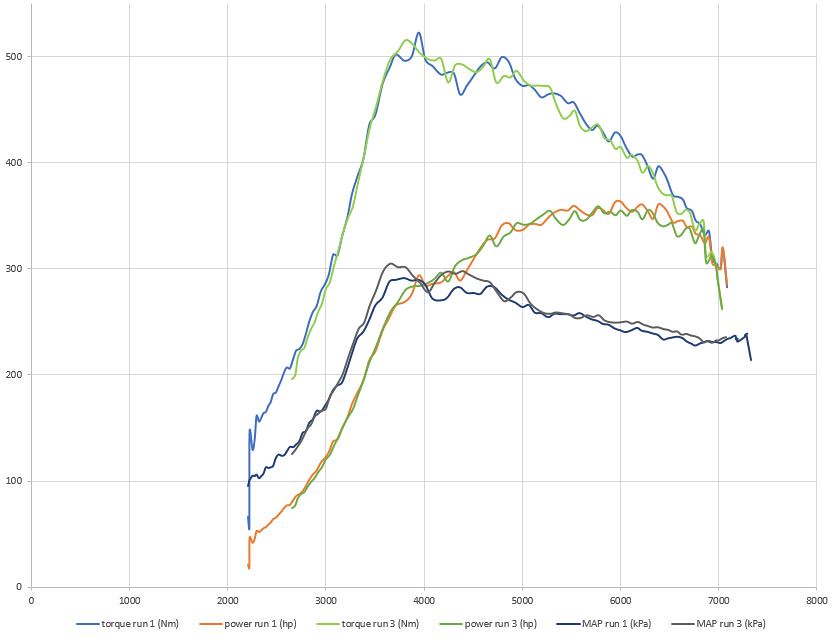

A while ago I was playing around with the jets in the amalvalve to get the boost pressure up a bit. While driving to check the boost pressure I figured I could do some test runs in 3rd gear from low RPM to the rev limiter and have my Dynojet measure the time, RPM, boost pressure and AFR.

With the Dynojet data exported to Excel I calculated the speed from the revs and with the speed increase over time I calculated the acceleration. The acceleration mutliplied with the weight (I estimated at 1400 kg, with me and some fuel in) gave the torque at the wheels. But since there is also some air drag I also added that, with a Cd of 0.33 and a total frontal area of 1.94 m2. That gave the total torque at the wheels. With that I calculated the flywheel power and torque. The transmission losses I estimated at 16.4%, as that is what I found on the internet from someone who had his Cosworth 4x4 on the rolling road (357 bhp at the wheels, 427 bhp at the flywheel).

According the the calculation the torque is about 515 Nm, which is about 380 lbf.ft and the power is about 360 bhp, which are very closer numbers for the setup I have (T34.48 with Siemens 55s). The boost is about 1.95 to 2.0 bar, so perhaps the torque could be a little bit higher still if I increased the boost to 2.2 bar.

I did 3 runs in total and the graphs are very close to each other, so no need for a rolling road anymore.

With the Dynojet data exported to Excel I calculated the speed from the revs and with the speed increase over time I calculated the acceleration. The acceleration mutliplied with the weight (I estimated at 1400 kg, with me and some fuel in) gave the torque at the wheels. But since there is also some air drag I also added that, with a Cd of 0.33 and a total frontal area of 1.94 m2. That gave the total torque at the wheels. With that I calculated the flywheel power and torque. The transmission losses I estimated at 16.4%, as that is what I found on the internet from someone who had his Cosworth 4x4 on the rolling road (357 bhp at the wheels, 427 bhp at the flywheel).

According the the calculation the torque is about 515 Nm, which is about 380 lbf.ft and the power is about 360 bhp, which are very closer numbers for the setup I have (T34.48 with Siemens 55s). The boost is about 1.95 to 2.0 bar, so perhaps the torque could be a little bit higher still if I increased the boost to 2.2 bar.

I did 3 runs in total and the graphs are very close to each other, so no need for a rolling road anymore.

The following users liked this post:

Mark V8 (23-08-2018)

#174

Near 100 bhp transmission loss seems like a lot. But maybe on the rollers the losses can be higher due to the tyres being between 2 rollers. According to the calculation my transmission losses are 60 bhp. But if the 16.4% is too low it would have more power at the flywheel, which seems unlikely for a T34.48.

#177

I thought the T34.48 was good for 360-370 bhp. But iím not sure of the 1400 kg either. On paper the 4x4 is 1310 kg, which does not leave much for me and the fuel. So maybe itís closer to 1420 kg, which would also mean the power would be higher.

#178

Live long and prosper!!

iTrader: (1)

There is a few of us on here including James who used to work with Stu had over 400bhp from a T34.48. But remember it's flat out. My turbo is a bit of a hybrid unit as it originally was a grp A turbo with a 34 restrictor. Which I had rebuilt and fitted a std escos 34 front housing.

it peaks around 36psi at 5500rpm and then drops off.

it peaks around 36psi at 5500rpm and then drops off.

#179

I guess your turbo is quite a bit different then. Mine peaks already at about 3600 rpm, as you can see from the graph. But the boost drops to about 1.3 bar when going to 7000 rpm. Yours might be more comparable to a T34.63 with the late spool and more power?

#181

Thatís very good power for any T34, let alone a .48! It does seem to make peak torque quite late. But that may be due to the rolling road that lets the engine speed up quicker than it would on the road, just like when youíre in a low gear on the road.

#183

A few years ago at the sprint event of the European Ford Event in Holland I noticed the rear wheels on another Cosworth moving forward quite a lot during the launch. I knew that Cosworth had the same yellow Powerflex bushes fitted in the rear beam as I have. So apparently there is still quite a lot of movement possible with those bushes. During a sprint it's not so bad, but in corners this can mean that the rear beam moves underneath the car, changing the toe setting of both rear wheels. I had already read a few times that the solid bushes that are available don't really compromise the ride, so I ordered a set of solid bushes last year.

At the time I had already put quite some effort into removing the old Powerflex bushes from the beam, but they wouldn't come out. But now it was really time to replace them, so this time I tried a bit harder and managed to remove the bushes without removing the whole rear beam from the car. Fortunately, fitting the solid bushes was very easy.

The reason I really wanted to remove the old bushes was because I also wanted a different exhaust on the car. And removing the bushes with the new exhaust on would be even more difficult. The reason for wanting a diferent exhaust is that the noise from the Mongoose is driving me crazy, especially on long runs on the motorway where it really had an annoying drone. I guess I must be getting a bit old.

Getting another exhaust was not so easy though. As with most Cosworth parts it had to come from the UK, but most sellers said it was too big to send. And when I finally found one that would send it the price was listed incorrectly and it turned out to be much more expensive. In the end I found a nice second hand Magnex exhaust with 4" tail pipe from Gary, and shipment was also not a problem in this case.

Fitting the exhaust was a nightmare though. I already knew it was not going to fit anyway due to the 6 degree rear beam. For that reason both centre boxes had to be moved about 4 cm to the front and the brackets fitted to the centre boxes had to lengthened to come back to the original place. But strangely that wasn't the only place where it didn't fit. It had to be adapted to quite a bit at the front too, to clear the chassis rail, arb and gearbox. On some locations it only has about 5 mm of room, but it's not touching anything, also not by movements of the engine. But unfortunately no pictures from the exhaust being fitted.

The noise from the exhaust is huge improvement. It is still not really quiet, but at idling it's a huge difference and also the annoying drone at motorway speeds is gone.

At the time I had already put quite some effort into removing the old Powerflex bushes from the beam, but they wouldn't come out. But now it was really time to replace them, so this time I tried a bit harder and managed to remove the bushes without removing the whole rear beam from the car. Fortunately, fitting the solid bushes was very easy.

The reason I really wanted to remove the old bushes was because I also wanted a different exhaust on the car. And removing the bushes with the new exhaust on would be even more difficult. The reason for wanting a diferent exhaust is that the noise from the Mongoose is driving me crazy, especially on long runs on the motorway where it really had an annoying drone. I guess I must be getting a bit old.

Getting another exhaust was not so easy though. As with most Cosworth parts it had to come from the UK, but most sellers said it was too big to send. And when I finally found one that would send it the price was listed incorrectly and it turned out to be much more expensive. In the end I found a nice second hand Magnex exhaust with 4" tail pipe from Gary, and shipment was also not a problem in this case.

Fitting the exhaust was a nightmare though. I already knew it was not going to fit anyway due to the 6 degree rear beam. For that reason both centre boxes had to be moved about 4 cm to the front and the brackets fitted to the centre boxes had to lengthened to come back to the original place. But strangely that wasn't the only place where it didn't fit. It had to be adapted to quite a bit at the front too, to clear the chassis rail, arb and gearbox. On some locations it only has about 5 mm of room, but it's not touching anything, also not by movements of the engine. But unfortunately no pictures from the exhaust being fitted.

The noise from the exhaust is huge improvement. It is still not really quiet, but at idling it's a huge difference and also the annoying drone at motorway speeds is gone.

#185

Last year I took the car to a slalom competition. Not that I had the illusion that it would be fast there, but just to have some fun. There are hardly any straights so the speed is quite low. The Cosworth really isn't suited well for such conditions, it's quite a big car for the tight corners. And the speed is also too low to make good use of the power band. Especially coming out of the tight corners the revs are too low for it to pick up well. And when the turbo begins to spool you are already at the next corner. Perhaps an experienced rally driver could do well with some left foot braking here, but not me. But anyway, I did have some fun!

#186

PassionFord Post Troll

Where did you get your alloy bushes from Marc and does your beam have enough clearance to the floor afterwards? I bought some from mk and had to machine spacers to effectively make them thicker as my beam was hard against the floor.

#188

Ever since I've taken the car to the track I have not really been happy anymore with the shocks. I have the feeling they don't have enough low speed damping, what makes the car roll quite a bit when turning into a corner and it also dives a bit much during braking. But then I started thinking about what else to use than the Koni shocks.

I have been thinking about getting a Gaz Gold or Black Art Design coilover set. As far as I know both are twin tube shocks with 1-way adjustment that combines compression and rebound damping in 1 adjuster. For both you hear quite a lot of good stories, mostly a bit better for the BADs than for the Gaz, but sometimes people are still saying they are not happy with them, or that the damping is not very equal for all shocks. Another option is the old type of Bilstein coilover as Ford used on the works cars back in the day. Those use monotube shocks with 41 mm inserts, which is supposed to be a better damper principle than the twin tube from Gaz, BAD and Koni. I would expect the quality from the Bilstein to be better than Gaz and BAD, but unfortunately the Bilsteins are not adjustment in damping and the 41 mm inserts are quite rare and therefore pricey now. Another option was to use 40 mm custom inserts from Bilstein and build my own shock housing. Quite a lot of parts can easily be bought, so especially a front coilover wouldn't be so difficult to make, but they still wouldn't be adjustable just like the 41 mm inserts. Yet another option was to a set from for instance Proflex or Reiger. Both are monotubes like the Bilsteins, but adjustable. Both will be very good as they are used in professional motorsports, but unfortunately the price will also reflect that.... So the last option was to find a second hand Proflex or Reiger set which would be more affordable. My preference would then go to Reiger, as Ford have been using them in the World Rally Championship since 1997, starting on the Escort WRC. The only problem is that Reigers for a Cosworth are impossible to find second hand. Proflex seems to be a bit easier to find second hand, so that is what I got in the end.

As these are quite old by now they are only 2-way adjustable, compared to the 3-way adjustability of new Proflex dampers. These have independent compression and rebound adjustment. On the new ones you can adjust low and high speed compression independently as well. But if I ever wanted it would be possible to convert these 2-ways into 3-ways adjustment.

I have been thinking about getting a Gaz Gold or Black Art Design coilover set. As far as I know both are twin tube shocks with 1-way adjustment that combines compression and rebound damping in 1 adjuster. For both you hear quite a lot of good stories, mostly a bit better for the BADs than for the Gaz, but sometimes people are still saying they are not happy with them, or that the damping is not very equal for all shocks. Another option is the old type of Bilstein coilover as Ford used on the works cars back in the day. Those use monotube shocks with 41 mm inserts, which is supposed to be a better damper principle than the twin tube from Gaz, BAD and Koni. I would expect the quality from the Bilstein to be better than Gaz and BAD, but unfortunately the Bilsteins are not adjustment in damping and the 41 mm inserts are quite rare and therefore pricey now. Another option was to use 40 mm custom inserts from Bilstein and build my own shock housing. Quite a lot of parts can easily be bought, so especially a front coilover wouldn't be so difficult to make, but they still wouldn't be adjustable just like the 41 mm inserts. Yet another option was to a set from for instance Proflex or Reiger. Both are monotubes like the Bilsteins, but adjustable. Both will be very good as they are used in professional motorsports, but unfortunately the price will also reflect that.... So the last option was to find a second hand Proflex or Reiger set which would be more affordable. My preference would then go to Reiger, as Ford have been using them in the World Rally Championship since 1997, starting on the Escort WRC. The only problem is that Reigers for a Cosworth are impossible to find second hand. Proflex seems to be a bit easier to find second hand, so that is what I got in the end.

As these are quite old by now they are only 2-way adjustable, compared to the 3-way adjustability of new Proflex dampers. These have independent compression and rebound adjustment. On the new ones you can adjust low and high speed compression independently as well. But if I ever wanted it would be possible to convert these 2-ways into 3-ways adjustment.

#189

The set of Proflex shocks I found came from a tarmac rally car, so they have pretty stiff springs fitted. There are no markings on the springs anymore, so I measured the length, thickness, number of coils etc. so I could estimate the spring rates. For the fronts it is somewhere around 90 N/mm (515 lb/in) and around 55 N/mm (315 lb/in) for the rears. I am planning on using front springs of 60 N/mm and rear springs of 30 N/mm, so the valving of the shocks needs to be changed too.

Since I like doing stuff myself I went looking on the internet to see if there was some info on how the Proflex shocks come apart, and yes there is:

And it doesn't seem so complicated either.

Since I like doing stuff myself I went looking on the internet to see if there was some info on how the Proflex shocks come apart, and yes there is:

And it doesn't seem so complicated either.

#190

PassionFord Post Troll

Looks straight forward, what oil do you use though and is it a case of full till it spills or is there a certain quantity?

#191

Advanced PassionFord User

There is a certain quantity and a decent quality too. You will need all new O rings and piston band gasket material.

they are remote reservoir gas pressurised units. They are easy to take apart but very difficult to reassemble correctly. If you donít have to kit you will fail. Your suspension will not work correctly and will be dangerous.

You have to know how to remove the air bubbles and purge the damper. If the pressure is incorrect or you have too much or too little oil, it will not work.

leave it to the professional people. They will balance them and match them correctly. This is not a home mechanic thing. I 100% guarantee you will make a complete balls of it.

they are remote reservoir gas pressurised units. They are easy to take apart but very difficult to reassemble correctly. If you donít have to kit you will fail. Your suspension will not work correctly and will be dangerous.

You have to know how to remove the air bubbles and purge the damper. If the pressure is incorrect or you have too much or too little oil, it will not work.

leave it to the professional people. They will balance them and match them correctly. This is not a home mechanic thing. I 100% guarantee you will make a complete balls of it.

#192

Advanced PassionFord User

Double post, apologies

#193

Thanks for the heads up and the warning! I do have some information how to assemble and them how to remove the air. So I will see how I will get on.

So I started taking them apart. Firstly I removed the front shock from the lower 'leg', where it immediately became obvious it needed new bump stops.

To open up the shock the upper dust cup needs to removed using a flange spanner.

To get to the internals the upper cup with the seal has to be removed. It is held in by a circlip from the top. Firstly the gas pressure needs to be taken off so the upper cup can be pressed down a bit and the circlip can be removed.

When the circlip is removed the damper rod can be removed from the shock.

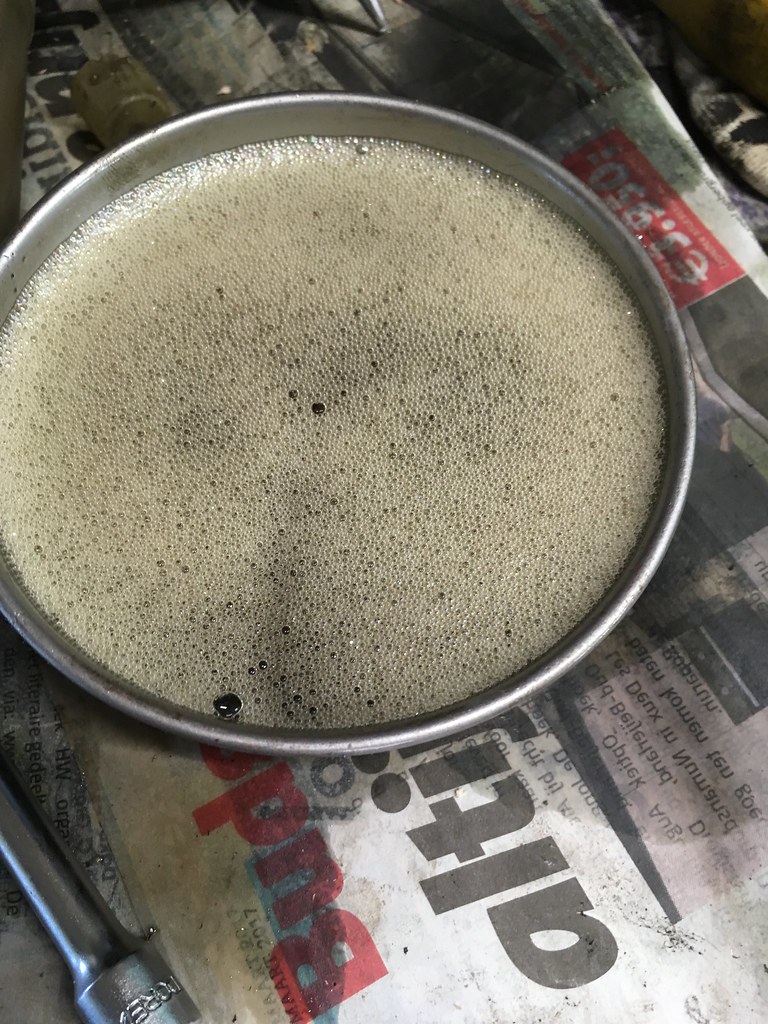

After that the oil can be drained from the shock housing. The oil in the rear dampers wasn't that bad, probably because the rear dampers have less weight to dampen and make a bigger stroke than the front ones.

This oil came from the rear dampers.

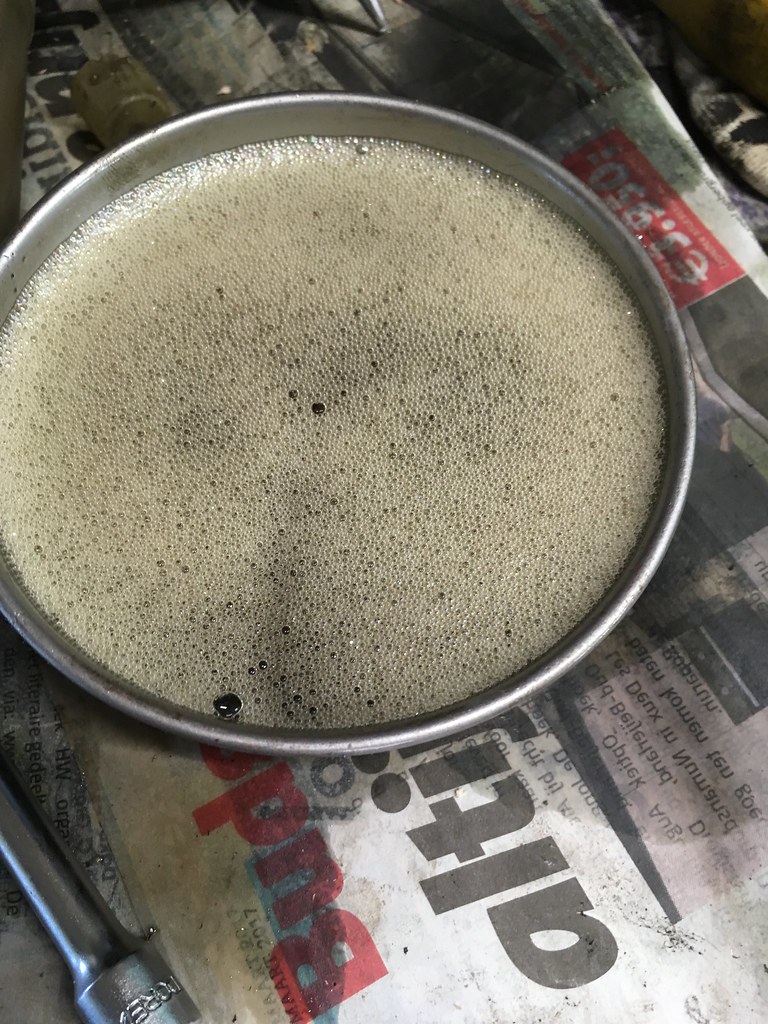

On the fronts the oil was a lot darker, so it probably had a much harder life.

And on one front damper the gas leaked to the oil. Opening the damper was like opening a bottle of coca cola after shaking it for a while.

So I started taking them apart. Firstly I removed the front shock from the lower 'leg', where it immediately became obvious it needed new bump stops.

To open up the shock the upper dust cup needs to removed using a flange spanner.

To get to the internals the upper cup with the seal has to be removed. It is held in by a circlip from the top. Firstly the gas pressure needs to be taken off so the upper cup can be pressed down a bit and the circlip can be removed.

When the circlip is removed the damper rod can be removed from the shock.

After that the oil can be drained from the shock housing. The oil in the rear dampers wasn't that bad, probably because the rear dampers have less weight to dampen and make a bigger stroke than the front ones.

This oil came from the rear dampers.

On the fronts the oil was a lot darker, so it probably had a much harder life.

And on one front damper the gas leaked to the oil. Opening the damper was like opening a bottle of coca cola after shaking it for a while.

#194

Advanced PassionFord User

Iím not denying you have an ability. I am saying you wonít get it right. Have you got all the spare seals and shims. Do you know what to revalue them to?

have you got access to a damper dyno? If you get it slightly wrong you will get a massive difference in performance. If you manage to get it perfect, you will still need to dyno them to set the adjuster.

have you got access to a damper dyno? If you get it slightly wrong you will get a massive difference in performance. If you manage to get it perfect, you will still need to dyno them to set the adjuster.

#195

Yes I have the seals and shims and other stuff I need and I also know how to revalve them. I don't have access to a damper dyno, but the person I spoke with who does this all the time said he never puts them on the dyno anyway, so he saw no need for me to do that.

What do you mean to dyno them to set the adjuster? The adjuster is there to fine tune them on the road. So why would you need a dyno for that?

What do you mean to dyno them to set the adjuster? The adjuster is there to fine tune them on the road. So why would you need a dyno for that?

#196

Advanced PassionFord User

I always used to dyno them after rebuild to set the adjusters. You canít expect something newly built or old unit serviced to go back together and match its opposite axle partner. So after a rebuild I would remove the knob off the adjusters and dynoíd them. I would get one in the range I wanted it, then dyno the other unit and set the adjuster pin to match. Once both units matched to within a few Newtons I would refit the knobs in exactly the same positions. This meant that if I altered one by one click I could alter the other one by exactly the same amount by the same one click.

It makes it easy to make specific track based adjustments by counting the adjustment clicks.

it also means that you have a perfectly balanced matched pair.

It makes it easy to make specific track based adjustments by counting the adjustment clicks.

it also means that you have a perfectly balanced matched pair.

Last edited by jonfoc; 04-08-2020 at 08:38 PM.

#197

I understand what you are saying about removing the adjusters and match them. But I don't think it is possible to do that with these dampers anyway. The adjusters are a one piece thing and can be rotated from fully open to fully closed and the knobs cannot be removed, so adjusting it like you said does not seem possible to me.

If you would want to match these dampers you'd need to fully build them, dyno them and if they are not the same you would then need to change the shims in order to get them completely equal, which would be an iterative process. It would take quite a long time as well, as each time you would need to remove the piston from the damper to revalve and then fill the damper, bleed the air, fill with nitrogen and re-dyno the damper. So I can't imagine they would do such a thing as standard. So I guess (hope?) that the shims have very tight tolerances, so that the damping would be equal by just putting the same shims in.

If you would want to match these dampers you'd need to fully build them, dyno them and if they are not the same you would then need to change the shims in order to get them completely equal, which would be an iterative process. It would take quite a long time as well, as each time you would need to remove the piston from the damper to revalve and then fill the damper, bleed the air, fill with nitrogen and re-dyno the damper. So I can't imagine they would do such a thing as standard. So I guess (hope?) that the shims have very tight tolerances, so that the damping would be equal by just putting the same shims in.

#198

Advanced PassionFord User

Yeah I completely understand what youíre saying. I rebuilt a few intrax units with the same adjuster process. It is a very Labour intensive process, itís what we had to do though to guarantee matched performance.

i wish you the best of luck and due to the fact there is no financial cost to how long you take, I say take your time. I canít say enough times, clean, clean, clean everything over and over. Make sure you have zero dirt in any areas. Use thread lock on the piston lock nut and maybe a centre punch to lock it on.

when you are gripping the rod, make sure you use an aluminium or plastic clamp so no damage is caused to the rod. If there are any positives on the rod, your seals will get torn when you slide them over. Donít try and repair any rod damage, get a new rod machined. If the rods are slightly bent, replace them. A bent rod will cause premature wear on seals. Your units are remote gas cans too. Gas will find the slightest of gaps to escape from.

good luck and take your time.

i wish you the best of luck and due to the fact there is no financial cost to how long you take, I say take your time. I canít say enough times, clean, clean, clean everything over and over. Make sure you have zero dirt in any areas. Use thread lock on the piston lock nut and maybe a centre punch to lock it on.

when you are gripping the rod, make sure you use an aluminium or plastic clamp so no damage is caused to the rod. If there are any positives on the rod, your seals will get torn when you slide them over. Donít try and repair any rod damage, get a new rod machined. If the rods are slightly bent, replace them. A bent rod will cause premature wear on seals. Your units are remote gas cans too. Gas will find the slightest of gaps to escape from.

good luck and take your time.

#199

Advanced PassionFord User

Oh and one other thing. Donít assume your new oil is clean. Filter it through a fine paper filter. It takes time but it will be clean after.

#200

Advanced PassionFord User

Sorry to keep posting but I keep remembering things.

With your shims, give them a gentle rub on some flat very fine emery paper. Another good tip is to turn them over too. They do ďdishĒ slightly over time.

if I remember anything else Iíll add it on.

With your shims, give them a gentle rub on some flat very fine emery paper. Another good tip is to turn them over too. They do ďdishĒ slightly over time.

if I remember anything else Iíll add it on.

The following users liked this post:

Adam-M (05-08-2020)