E30 Touring 1UZFE V8

#1

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Not a ford I know, but just thought I would share my project with anyone interested, originally posted on E30 Zone:

Basically back in late 2010 I picked up an L reg touring from a member on here (apologies if you read this, but I have forgotten your name) that had some rear axle issues.

The car was a bargain, considering the rear axle was slated to be replaced anyway, and the bodywork was in excellent condition, so a decent basis for the project. Will fire some pictures of the car at the weekend.

So, the vehicle was dragged from manchester back to birmingham and was sat there while a friend and I decided what to do to it.

Around the same sort of time, another friend was deciding to sell his Lexus LS400 ( 4.0 V8 ) so it was purchased and the engine, gearbox, running gear, electrics, uprights, brakes etc etc were removed and thrown in to the work shop.

The engine in question: (generic image)

Now, the lexus V8 sounds good but only makes around 300bhp with breathing mods, which is good enough to start with but not enough for the finished article. But that can be addressed later.

The good thing is that this engine was removed from a 1991 H reg, so has the stronger bottom end. Result.

Now, this is where the 1st problem was encountered. Lexus only used this engine with an automatic transmission. No good for the track/drift car that we had in mind. But how hard can it be to bolt a manual box up?? Famous last words........

So, the transmission was removed along with the torque converter and flex plate, and sold on ebay for the princely sum of £12. Bargain.

We then ripped the engine, gear box and prop out of the touring, along with the abs, brake servo and everything else that would be in the way of the V8, in preparation for dropping it in.

Would you believe, it simply slotted in with no bother at all??

So we quickly fabbed up some mounts and ordered some "hockey puk" mounts from a land rover (£7 bargain) and the engine was in and sitting perfectly around 3 inches in front of the bulk head!

To be continued....

Basically back in late 2010 I picked up an L reg touring from a member on here (apologies if you read this, but I have forgotten your name) that had some rear axle issues.

The car was a bargain, considering the rear axle was slated to be replaced anyway, and the bodywork was in excellent condition, so a decent basis for the project. Will fire some pictures of the car at the weekend.

So, the vehicle was dragged from manchester back to birmingham and was sat there while a friend and I decided what to do to it.

Around the same sort of time, another friend was deciding to sell his Lexus LS400 ( 4.0 V8 ) so it was purchased and the engine, gearbox, running gear, electrics, uprights, brakes etc etc were removed and thrown in to the work shop.

The engine in question: (generic image)

Now, the lexus V8 sounds good but only makes around 300bhp with breathing mods, which is good enough to start with but not enough for the finished article. But that can be addressed later.

The good thing is that this engine was removed from a 1991 H reg, so has the stronger bottom end. Result.

Now, this is where the 1st problem was encountered. Lexus only used this engine with an automatic transmission. No good for the track/drift car that we had in mind. But how hard can it be to bolt a manual box up?? Famous last words........

So, the transmission was removed along with the torque converter and flex plate, and sold on ebay for the princely sum of £12. Bargain.

We then ripped the engine, gear box and prop out of the touring, along with the abs, brake servo and everything else that would be in the way of the V8, in preparation for dropping it in.

Would you believe, it simply slotted in with no bother at all??

So we quickly fabbed up some mounts and ordered some "hockey puk" mounts from a land rover (£7 bargain) and the engine was in and sitting perfectly around 3 inches in front of the bulk head!

To be continued....

#2

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Anyway, with the lump in and roughly where it needs to be, we decided to remove it and sort the gearbox issue.

After much digging we concluded that the w58 would be no where near strong enough, so we sourced an R154 from a manual supra turbo.

Big old gearbox, but mega strong and has a removable bell housing.

Prior to fitting the box, a flywheel and clutch assy was needed. A little bit of digging later and a toyota celica gt4 clutch and flywheel was mine for the basement price of £20, with a new friction plate. Mint.

Now, while the centre bore in the flywheel does sit perfectly on the V8 crank, the pcd of the bolt holes is different, 6mm IIRC. So same calls later and a billet steel flywheel with integral ring gear was on its way for £250. Yet another bargain IMO.

So, flywheel on, retained with longer ARP bolts, clutch bolted up and all was right with the world.

The bell housing was then removed from the R154 and it was offered up to the engine.

After a little more digging, I found out that a spacer plate was required to mate the R154 to the auto bell housing (thankfully retained when the auto was sold) and that a very kind chap had quickly knocked one up in CAD.

So the file was given to a friend of mine and the spacer turned up the next day, machined from a billet of 35mm ally. After some tapping, reaming and swearing, we found out that some of the CAD details were a touch wrong, but no biggie, and the plate was given a little love on the milling machine.

So bolt all of those bits together and you have this:

Big and heavy, but no real internal mods needed provided we ONLY want 500bhp lol.

TBC.....

After much digging we concluded that the w58 would be no where near strong enough, so we sourced an R154 from a manual supra turbo.

Big old gearbox, but mega strong and has a removable bell housing.

Prior to fitting the box, a flywheel and clutch assy was needed. A little bit of digging later and a toyota celica gt4 clutch and flywheel was mine for the basement price of £20, with a new friction plate. Mint.

Now, while the centre bore in the flywheel does sit perfectly on the V8 crank, the pcd of the bolt holes is different, 6mm IIRC. So same calls later and a billet steel flywheel with integral ring gear was on its way for £250. Yet another bargain IMO.

So, flywheel on, retained with longer ARP bolts, clutch bolted up and all was right with the world.

The bell housing was then removed from the R154 and it was offered up to the engine.

After a little more digging, I found out that a spacer plate was required to mate the R154 to the auto bell housing (thankfully retained when the auto was sold) and that a very kind chap had quickly knocked one up in CAD.

So the file was given to a friend of mine and the spacer turned up the next day, machined from a billet of 35mm ally. After some tapping, reaming and swearing, we found out that some of the CAD details were a touch wrong, but no biggie, and the plate was given a little love on the milling machine.

So bolt all of those bits together and you have this:

Big and heavy, but no real internal mods needed provided we ONLY want 500bhp lol.

TBC.....

#3

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Now that the engine and box were all together, the final hurdle was how to actuate the clutch....

The standard R154 clutch system is a pull clutch with a pivot on the bell housing. Which we arent using. Plus the Celica GT4 clutch we are using is a push item.

So, a little research and one of these weee beasties was winging its way over to us from south africa:

Having done the maths, and knowing that the master cylinder would give us the required throw from the slave, the only problem we needed to over come was the fact that the sleve in the gearbox wasnt really long enough once the CSC was shimmed out to where it needed to be.

Plus the bearing on the clutch cover plate side of the slave cylinder had a flat face....

So, to kill 2 birds with one stone, I quickly knocked up aspacer on the lathe that would fit over the flat faced bearing. This spacer would have a hardened bull nosed contact patch to the cover plate, so thats 1 problem fixed, plus the extra 20mm depth that this spacer added meant that the slave cylinder sat on to the gearbox input shaft sleve by a further 20mm.

Result.

So, engine box and clutch done, time to throw it all in and see if we have a clutch pedal....

Clutch works lovely, maybe a touch heavier than I would like, but we cant have everything! PS if you look through the hole in the bulk head where the heater usually sits, you can see the gear stick

So with the engine in, attention could be turned to the small problem of manifolds, as the standard tubular units are, well crap basically. Plus they dont fit...

Here is the room we have to work with:

As you can see, the steering rack is also goin to be an issue, but we will come back to that...

The standard R154 clutch system is a pull clutch with a pivot on the bell housing. Which we arent using. Plus the Celica GT4 clutch we are using is a push item.

So, a little research and one of these weee beasties was winging its way over to us from south africa:

Having done the maths, and knowing that the master cylinder would give us the required throw from the slave, the only problem we needed to over come was the fact that the sleve in the gearbox wasnt really long enough once the CSC was shimmed out to where it needed to be.

Plus the bearing on the clutch cover plate side of the slave cylinder had a flat face....

So, to kill 2 birds with one stone, I quickly knocked up aspacer on the lathe that would fit over the flat faced bearing. This spacer would have a hardened bull nosed contact patch to the cover plate, so thats 1 problem fixed, plus the extra 20mm depth that this spacer added meant that the slave cylinder sat on to the gearbox input shaft sleve by a further 20mm.

Result.

So, engine box and clutch done, time to throw it all in and see if we have a clutch pedal....

Clutch works lovely, maybe a touch heavier than I would like, but we cant have everything! PS if you look through the hole in the bulk head where the heater usually sits, you can see the gear stick

So with the engine in, attention could be turned to the small problem of manifolds, as the standard tubular units are, well crap basically. Plus they dont fit...

Here is the room we have to work with:

As you can see, the steering rack is also goin to be an issue, but we will come back to that...

#4

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Right, after taking a bit of a look at manifolds, and sorting the passenger side out, shown below, this was shelved, as the ECU and CDS tubing for the cage arrived.

The ECU in question is a Megasquirt 2.2, of which I have no experience, and its a solder it together yourself job! That is about where we are with the project so far.

To do:

Solder ecu together and make wiring loom/map the thing

Make decent pipe bender

Use decent pipe bender to make cage (ambitious)

Sort fuel system

Sort brake system (sourced remote servos)

Move steering rack

Sort cooling system

Change rear dif for massive lexus one (and shafts)

Finish prop

Do interior

Drive like a lunatic

I shall update when there is progress, but as I mentioned, ECU soldering is all I shall be doing for a while and I can only work on the thing on sundays.

The ECU in question is a Megasquirt 2.2, of which I have no experience, and its a solder it together yourself job! That is about where we are with the project so far.

To do:

Solder ecu together and make wiring loom/map the thing

Make decent pipe bender

Use decent pipe bender to make cage (ambitious)

Sort fuel system

Sort brake system (sourced remote servos)

Move steering rack

Sort cooling system

Change rear dif for massive lexus one (and shafts)

Finish prop

Do interior

Drive like a lunatic

I shall update when there is progress, but as I mentioned, ECU soldering is all I shall be doing for a while and I can only work on the thing on sundays.

#5

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Quick update,

After seeing the price of a decent cage, we decided to order some CDS and have a go at making our own. Brave I know, but if you dont try then you never know.

The tube spec is a little ott, but safety 1st. OD 41mm ( 1" & 5/8 ) with a wall thickness of 3.3mm

Purchased a clarke pipe bender (a mistake) which included various dies, one of which wasnt too dissimilar to the OD of the tube in question.

1st attempt, tube kinked badly. Which was half expected.

2nd attempt, tube filled with kiln dried sand and compacted, with both tube ends sealed up. This started off very promising, but when we got to roughly 20degrees, the tube burst! Spraying sand everywhere I might add. Unexpected.

So, the clarke job was thrown away and some plans knocked up to make a decent tube former, which would have a static die and a rotating die that would "form" the bend and should prevent kinking etc.

With that in mind, I quickly knocked up a couple of dies in CAD and emailed them to a friend. The next day, this turned up:

Shown next to my htc desire HD for size comparison. Basically its massive lol

The next step was to quickly knock up a frame to mount it in, which would also act as the forming guide. A little cutting drilling and welding later and we have the almost finished article:

Originally we had thought to make a cam and a handle which we could hand crank, however the thickness of the tube and the effort involved led to a quick rethink....

The bottle jack from the original clarke (shite) pipe bender was fitted in to a cradle and to the former, and it was time to try another bend....

Lo and behold:

An awesome result in my opinion.

So, we crack on with the cage on sunday. Fingers crossed...

After seeing the price of a decent cage, we decided to order some CDS and have a go at making our own. Brave I know, but if you dont try then you never know.

The tube spec is a little ott, but safety 1st. OD 41mm ( 1" & 5/8 ) with a wall thickness of 3.3mm

Purchased a clarke pipe bender (a mistake) which included various dies, one of which wasnt too dissimilar to the OD of the tube in question.

1st attempt, tube kinked badly. Which was half expected.

2nd attempt, tube filled with kiln dried sand and compacted, with both tube ends sealed up. This started off very promising, but when we got to roughly 20degrees, the tube burst! Spraying sand everywhere I might add. Unexpected.

So, the clarke job was thrown away and some plans knocked up to make a decent tube former, which would have a static die and a rotating die that would "form" the bend and should prevent kinking etc.

With that in mind, I quickly knocked up a couple of dies in CAD and emailed them to a friend. The next day, this turned up:

Shown next to my htc desire HD for size comparison. Basically its massive lol

The next step was to quickly knock up a frame to mount it in, which would also act as the forming guide. A little cutting drilling and welding later and we have the almost finished article:

Originally we had thought to make a cam and a handle which we could hand crank, however the thickness of the tube and the effort involved led to a quick rethink....

The bottle jack from the original clarke (shite) pipe bender was fitted in to a cradle and to the former, and it was time to try another bend....

Lo and behold:

An awesome result in my opinion.

So, we crack on with the cage on sunday. Fingers crossed...

#6

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Right, well after an early start on Sunday, a decent days work was put in.

Firstly finalised the bottle jack instal on the pipe bender:

Then got to work making the cage....

Fairly self explanatory really:

After the roll hoop, the tubes that run up the a pillar were bent up and tacked in place

Then a cross piece was bent to triangulate the 2 a pillar tubes to the bulk head, cant really see in the above picture but the horizontal bar is bent towards the bay....

Then bent up a piece to run along the top of the screen which is to be welded to the inner roof skin.

The reason everything looks on the piss in the last pic is that I have cut 2 holes in the floor and dropped the roll hoop through, to allow me access to weld around the whole of the tube intersections.

More at the weekend I hope.

Firstly finalised the bottle jack instal on the pipe bender:

Then got to work making the cage....

Fairly self explanatory really:

After the roll hoop, the tubes that run up the a pillar were bent up and tacked in place

Then a cross piece was bent to triangulate the 2 a pillar tubes to the bulk head, cant really see in the above picture but the horizontal bar is bent towards the bay....

Then bent up a piece to run along the top of the screen which is to be welded to the inner roof skin.

The reason everything looks on the piss in the last pic is that I have cut 2 holes in the floor and dropped the roll hoop through, to allow me access to weld around the whole of the tube intersections.

More at the weekend I hope.

#7

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Some more action last week, I started off by having to do a repair to one of my dads golf clubs lol, the tool had snapped the carbon shaft!

So I turned a tapered insert, bonded it in with 3M 9323 adhesive, sanded it down, and wrapped the whole shabang in prepreg UD carbon.

Here it is prior to going in to tha clave at work:

So with that all sorted (ended up mint by the by, and mega strong!) it was back to the cage fabrication.

Rear door members tacked in car line to transfer forces from a head on (god forbid) along with front door bars which are somewhat of a compramise due to having to get my fat ass in and out of the car!

Additionally the bars going across the car at the bottom of the roll hoop and between the rear turrets have been tacked in place.

Next we moved on to the plating of the rear turrets to give a solid mount for some triangulation.

May have gone a bit OTT with the welding in the close up lol but you can never be too sure....

And then as luck would have it, the gas ran out for the MIG. Tried to continue using the TIG, but it was a huge pain in the arse, so decided to get the "kart" out and spend the rest of the day acting like a hooligan in the fields lol

Its quite entertaining if the weather is ok, as the power to weight is quite high!

Well thats all for now, more after the weekend no doubt.

So I turned a tapered insert, bonded it in with 3M 9323 adhesive, sanded it down, and wrapped the whole shabang in prepreg UD carbon.

Here it is prior to going in to tha clave at work:

So with that all sorted (ended up mint by the by, and mega strong!) it was back to the cage fabrication.

Rear door members tacked in car line to transfer forces from a head on (god forbid) along with front door bars which are somewhat of a compramise due to having to get my fat ass in and out of the car!

Additionally the bars going across the car at the bottom of the roll hoop and between the rear turrets have been tacked in place.

Next we moved on to the plating of the rear turrets to give a solid mount for some triangulation.

May have gone a bit OTT with the welding in the close up lol but you can never be too sure....

And then as luck would have it, the gas ran out for the MIG. Tried to continue using the TIG, but it was a huge pain in the arse, so decided to get the "kart" out and spend the rest of the day acting like a hooligan in the fields lol

Its quite entertaining if the weather is ok, as the power to weight is quite high!

Well thats all for now, more after the weekend no doubt.

Trending Topics

#8

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Right, spent 6 bloody hours on the motorway saturday doing a total of 120 miles! Traffic sucks balls.

The end result of this nightmare is a pair of lightweight bucket seats that we needed prior to finishing the cage, just to make sure we didnt encroach on the driving position too much.

So on sunday with a new cylinder of welding gas, we cracked on with the cage:

The nearly vertical members in the above picture are to prevent the cage collapsing in circumstances like this poor guy experienced:

A freak accident with wierd circumstances, but I dont fancy the cage crushing my helmet, so the extra bracing went in! For those interested, the thread covering the destruction of the above audi is here: http://www.motorgeek.com/viewtopic.p...6273&start=225

With the front all braced and a seat thrown in so we could make sure that we can get in/out (just) we moved on to the rear section of the cage, and the bracing for the roll hoop:

And then the cross bracing to add torsional stiffness:

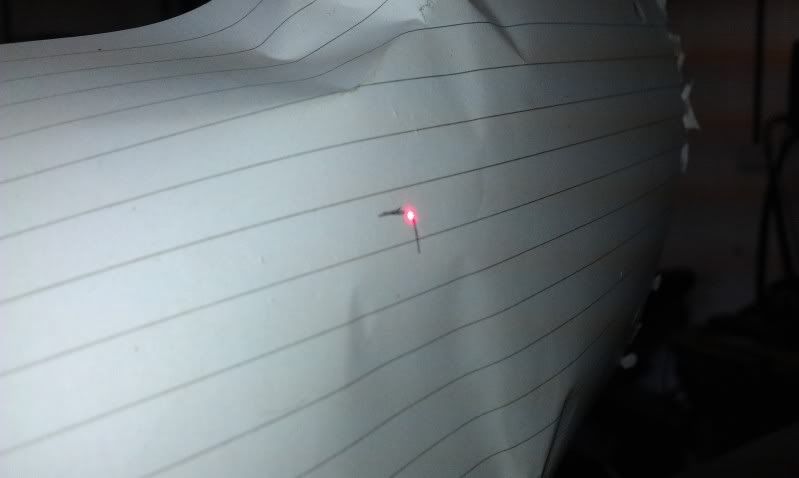

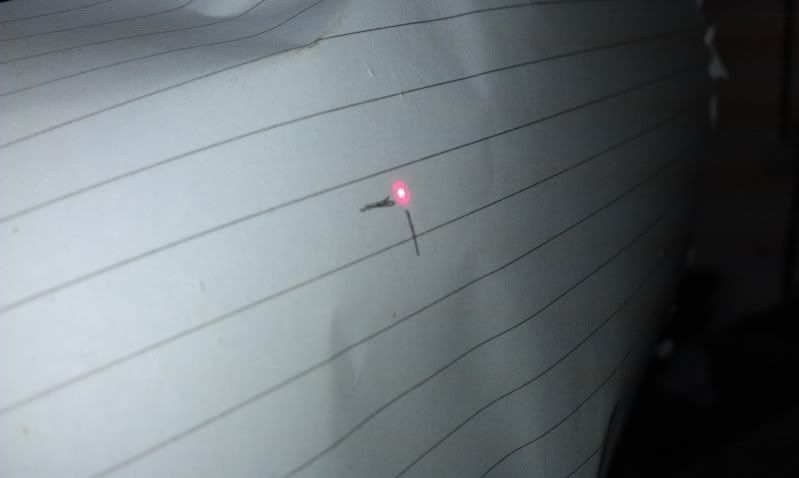

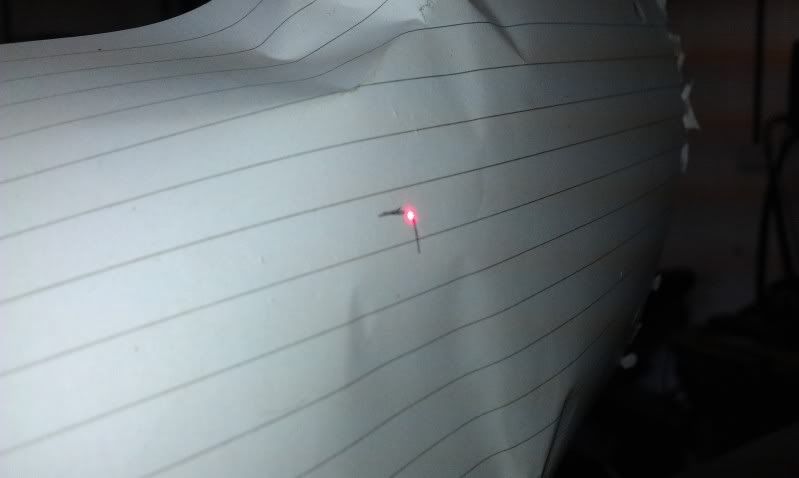

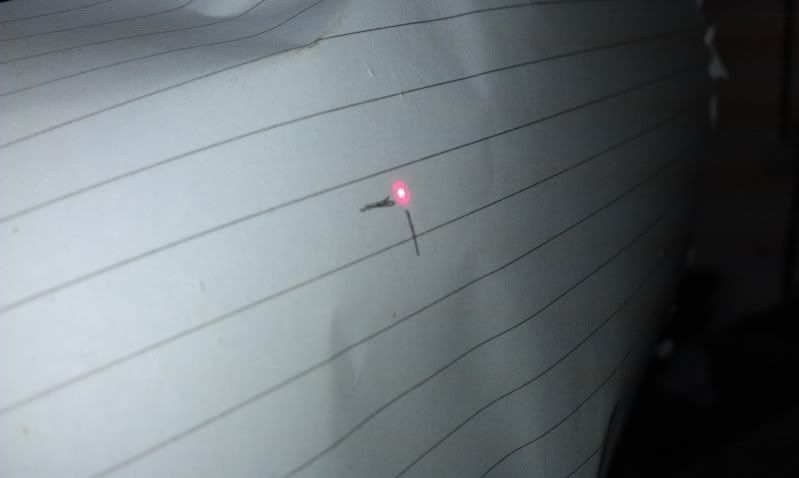

With that all welded up, we decided to do a quick stiffness test. Prior to fitting the cage, we mounted a laser level on the front corner of the car, pointing at a target mounted on the opposite rear corner.

We marked the point at which the pointer was hitting the target, then we jacked the front corner of the car up so that both near side wheels were off the floor and the car was in torsion.

We then marked the changed position of the point, and measured the difference:

We did this again with the finished cage all welded up, and with the exact same test, the difference in position of the laser pointer was less than 1/3rd. Stiff is good!

After all this messing around and the subsequent back patting, it was getting pretty late on, so we decided to just do a quick job to finish off.

As you may be able to tell from the pictures of the engine bay, getting the master cylinder to fit is going to be a nightmare, so we decided to mount the master cylinder, without servo unit, in the passenger footwell, with the intention of running 2 remote servo's in the boot.

With this firmly in mind, we hacked up the mounting bracket, modified some bell cranks and ended up with this:

The horizontal bar running along the bulkhead is the standard BMW jobby, which takes the pedal movement and transfers it to a bell crank that changes it to movement in car line, through the bulk head. Whereas our modified version keeps the movement across the car and our bell crank simply reverses its direction. It was simply a matter of then bracing the master cylinder to resist forces in the appropriate direction.

Works a treat. More next weekend.

The end result of this nightmare is a pair of lightweight bucket seats that we needed prior to finishing the cage, just to make sure we didnt encroach on the driving position too much.

So on sunday with a new cylinder of welding gas, we cracked on with the cage:

The nearly vertical members in the above picture are to prevent the cage collapsing in circumstances like this poor guy experienced:

A freak accident with wierd circumstances, but I dont fancy the cage crushing my helmet, so the extra bracing went in! For those interested, the thread covering the destruction of the above audi is here: http://www.motorgeek.com/viewtopic.p...6273&start=225

With the front all braced and a seat thrown in so we could make sure that we can get in/out (just) we moved on to the rear section of the cage, and the bracing for the roll hoop:

And then the cross bracing to add torsional stiffness:

With that all welded up, we decided to do a quick stiffness test. Prior to fitting the cage, we mounted a laser level on the front corner of the car, pointing at a target mounted on the opposite rear corner.

We marked the point at which the pointer was hitting the target, then we jacked the front corner of the car up so that both near side wheels were off the floor and the car was in torsion.

We then marked the changed position of the point, and measured the difference:

We did this again with the finished cage all welded up, and with the exact same test, the difference in position of the laser pointer was less than 1/3rd. Stiff is good!

After all this messing around and the subsequent back patting, it was getting pretty late on, so we decided to just do a quick job to finish off.

As you may be able to tell from the pictures of the engine bay, getting the master cylinder to fit is going to be a nightmare, so we decided to mount the master cylinder, without servo unit, in the passenger footwell, with the intention of running 2 remote servo's in the boot.

With this firmly in mind, we hacked up the mounting bracket, modified some bell cranks and ended up with this:

The horizontal bar running along the bulkhead is the standard BMW jobby, which takes the pedal movement and transfers it to a bell crank that changes it to movement in car line, through the bulk head. Whereas our modified version keeps the movement across the car and our bell crank simply reverses its direction. It was simply a matter of then bracing the master cylinder to resist forces in the appropriate direction.

Works a treat. More next weekend.

#9

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Not a lot done this weekend as we are waiting for delivery of some bits.

Finished off the mounting of the drivers and passenger seats:

This was a time consuming job, with a lot of in and outing of both seats and tacking/cutting and retacking of brackets etc. Happy with the finished result though!

Next moved on to the harness mouning points, welding some strengthening plates to which the eyelets need to be mounted etc. No pics really, as its straight forward chod.

To finish off I had to turn some fittings for my vacuum pump set up, so I can crack on with some carbon work ive been asked to do, so my partner in crime decided to make us a gearnob lol.

He located a decent block of holly from the wood shed (scheduled to be burnt to keep us warm in the winter!) and proceeded to make a large amount of wood shavings on the wood turning lathe lol.

Which resulted in this:

A bit of TLC and it will do nicely I think! Plus its very light

Anyway, on to more exciting things at the weekened (I hope)

Finished off the mounting of the drivers and passenger seats:

This was a time consuming job, with a lot of in and outing of both seats and tacking/cutting and retacking of brackets etc. Happy with the finished result though!

Next moved on to the harness mouning points, welding some strengthening plates to which the eyelets need to be mounted etc. No pics really, as its straight forward chod.

To finish off I had to turn some fittings for my vacuum pump set up, so I can crack on with some carbon work ive been asked to do, so my partner in crime decided to make us a gearnob lol.

He located a decent block of holly from the wood shed (scheduled to be burnt to keep us warm in the winter!) and proceeded to make a large amount of wood shavings on the wood turning lathe lol.

Which resulted in this:

A bit of TLC and it will do nicely I think! Plus its very light

Anyway, on to more exciting things at the weekened (I hope)

#10

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Not really had much chance to do anything this weekend, so not a great deal to say!

Knocked up some exhaust manifold flanges in CAD and had them laser cut from 316 stainless:

Bought a hydro hand brake for the bargain sum of £60, just needs a little TLC:

Hopefully will get a call to say that my schedule 40 316 stainless bends are ready in the next day or so, and will crack on with the exhaust at the weekend.

Knocked up some exhaust manifold flanges in CAD and had them laser cut from 316 stainless:

Bought a hydro hand brake for the bargain sum of £60, just needs a little TLC:

Hopefully will get a call to say that my schedule 40 316 stainless bends are ready in the next day or so, and will crack on with the exhaust at the weekend.

#11

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Right, no sign of the bends so the manifolds have been put on hold for now, although there is still more than enough work to be done...

We started off by soldering the ecu together. We started with this (image shamelessly stolen from the interweb as I didnt take a picture prior to starting the soldering):

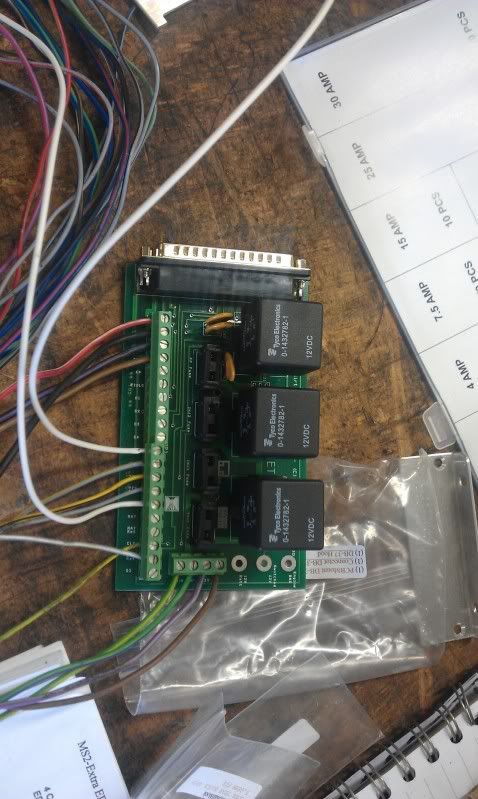

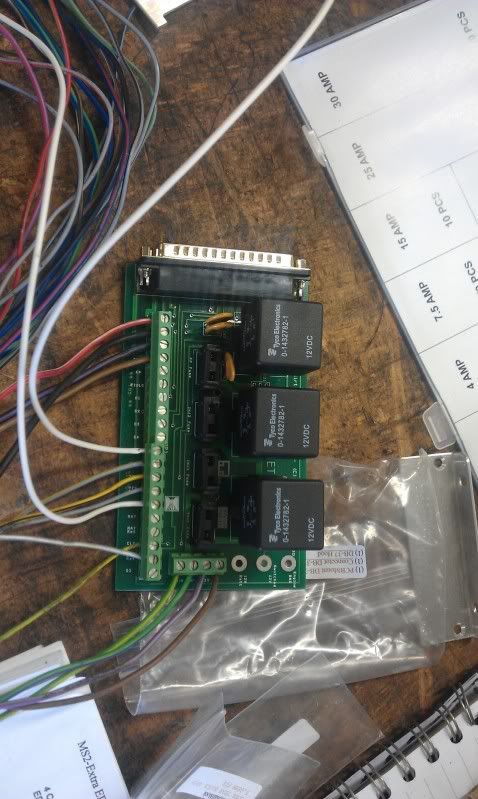

and ended up with this (ECU):

and this (Relay Board):

Then we had to make and solder up a cable which would link the ecu to the relay/power board, which ended up looking like this:

With that all done, we mounted the boards in the car just temporarily so that we can test everything when its all wired up:

Then, once we had grown bored of soldering, we decided to remove the rear diff, as it was grumbling and probably wouldnt like V8 power anyway.

So after much swearing and hitting of things with hammers, we ended up with a diff on the bench:

And just to confirm that it was the cause of the grumble, we quickly knocked up a test jig:

Thankfully it was the source of the problem and is in laymans terms FUBAR. But not to worry, as we have some potential replacements, shown here:

At the far end we have the standard 318 touring diff (boooo)

In the middle we have the diff from an LS400, massive (38kg) and no doubt capable of taking the horses, but appears to be a simple open diff (boooo)

The closest diff however seems to be the best choice. It is from a mk3 supra turbo, which coincidentally is the source of the gearbox we are using, and is an LSD. It is equally massive compared to the LS400 diff and just as heavy, but looks like it will fit quite easily and will no doubt take the power.

With a little bit of love, the diff now sits in the rear subframe nice and snug, so more pictures to come after the weekend.

We started off by soldering the ecu together. We started with this (image shamelessly stolen from the interweb as I didnt take a picture prior to starting the soldering):

and ended up with this (ECU):

and this (Relay Board):

Then we had to make and solder up a cable which would link the ecu to the relay/power board, which ended up looking like this:

With that all done, we mounted the boards in the car just temporarily so that we can test everything when its all wired up:

Then, once we had grown bored of soldering, we decided to remove the rear diff, as it was grumbling and probably wouldnt like V8 power anyway.

So after much swearing and hitting of things with hammers, we ended up with a diff on the bench:

And just to confirm that it was the cause of the grumble, we quickly knocked up a test jig:

Thankfully it was the source of the problem and is in laymans terms FUBAR. But not to worry, as we have some potential replacements, shown here:

At the far end we have the standard 318 touring diff (boooo)

In the middle we have the diff from an LS400, massive (38kg) and no doubt capable of taking the horses, but appears to be a simple open diff (boooo)

The closest diff however seems to be the best choice. It is from a mk3 supra turbo, which coincidentally is the source of the gearbox we are using, and is an LSD. It is equally massive compared to the LS400 diff and just as heavy, but looks like it will fit quite easily and will no doubt take the power.

With a little bit of love, the diff now sits in the rear subframe nice and snug, so more pictures to come after the weekend.

#12

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Right, after a little break due to work commitments, we decided to throw some fuel in the thing and see if starts!

Bear in mind that its just a thrown together loom, dodgy map, no lambda sensor or headers, so its a bit of a lash up.

1st attempt:

http://smg.photobucket.com/albums/v6...=VIDEO0016.mp4

Hopefully prop and drive shafts sorted after next weekend, then its a load of tidying up!

Bear in mind that its just a thrown together loom, dodgy map, no lambda sensor or headers, so its a bit of a lash up.

1st attempt:

http://smg.photobucket.com/albums/v6...=VIDEO0016.mp4

Hopefully prop and drive shafts sorted after next weekend, then its a load of tidying up!

#15

Lost for life.....

Join Date: Jan 2008

Location: under my car

Posts: 441

Likes: 0

Received 0 Likes

on

0 Posts

More then 12 years back I was at the Essen motorshow in Germany.

On the parking pulled up a E30 Touring but with a very deep sound.

The rear wheel arches had been pulled a bit, and fitted 18" wheels.

I asked the owner what it was, and he showed me the engine.

3.8 M5 engine bored to 4.0 with fastcams and intake manifold and special exhaust system from Kelleners.

He said it made 380 BHP.......

I still think of that car from time to time....

So why did you not use a M3 or M5 engine with or without turbo....

I think easy/cheap and more power....

Good luck with the build..

I will follow this thread.

On the parking pulled up a E30 Touring but with a very deep sound.

The rear wheel arches had been pulled a bit, and fitted 18" wheels.

I asked the owner what it was, and he showed me the engine.

3.8 M5 engine bored to 4.0 with fastcams and intake manifold and special exhaust system from Kelleners.

He said it made 380 BHP.......

I still think of that car from time to time....

So why did you not use a M3 or M5 engine with or without turbo....

I think easy/cheap and more power....

Good luck with the build..

I will follow this thread.

#16

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

More then 12 years back I was at the Essen motorshow in Germany.

On the parking pulled up a E30 Touring but with a very deep sound.

The rear wheel arches had been pulled a bit, and fitted 18" wheels.

I asked the owner what it was, and he showed me the engine.

3.8 M5 engine bored to 4.0 with fastcams and intake manifold and special exhaust system from Kelleners.

He said it made 380 BHP.......

I still think of that car from time to time....

So why did you not use a M3 or M5 engine with or without turbo....

I think easy/cheap and more power....

Good luck with the build..

I will follow this thread.

On the parking pulled up a E30 Touring but with a very deep sound.

The rear wheel arches had been pulled a bit, and fitted 18" wheels.

I asked the owner what it was, and he showed me the engine.

3.8 M5 engine bored to 4.0 with fastcams and intake manifold and special exhaust system from Kelleners.

He said it made 380 BHP.......

I still think of that car from time to time....

So why did you not use a M3 or M5 engine with or without turbo....

I think easy/cheap and more power....

Good luck with the build..

I will follow this thread.

Regards the question of engine choice: Firstly, relative to my income, an M3 or M5 V8 is not cheap. The 1UZFE was ~ £250. Thats cheap.

Personally, I think that a large part of the fun is in the making. Overcoming problems and re-engineering certain aspects of the overall package float my boat much more than a plug and play solution.

Secondly, with the addition of a suitable turbo, I dont think 400-450 would be too much of a problem, so plenty of scope for improvement there. Which is the main reason that everything is so strong. The gearbox will take 500 ponies no bother, as will the rest of the drive train.

#18

Lucifer II - 666

Looks good.

That crashed cage has no under roof cross bars and the aditional bar you've added wouldn't have prevented his roof collapsing how it did without the cross cars.

That crashed cage has no under roof cross bars and the aditional bar you've added wouldn't have prevented his roof collapsing how it did without the cross cars.

#19

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Seriously though, I am not having that happen to me. I would put in as much steel as necessary to avoid that, and I am confident that the cage I have is man enough for the job.

#20

very nice work here and quite talernted too

as far as the cage goes it would have been lighter in 50x2 rather than the 38x3 also with a bigger span stronger to ! im a little confused to have built the front legs as a hoop then put roof bars in ? sorry if im wrong but that whats it looks like mate , so if you have the new fia criteria is a front hoop (acting as a screen bar) center hoop with short exstentions from the front to middle then with a drop bar ! will be a great car when done , im going to keep a eye on this

as far as the cage goes it would have been lighter in 50x2 rather than the 38x3 also with a bigger span stronger to ! im a little confused to have built the front legs as a hoop then put roof bars in ? sorry if im wrong but that whats it looks like mate , so if you have the new fia criteria is a front hoop (acting as a screen bar) center hoop with short exstentions from the front to middle then with a drop bar ! will be a great car when done , im going to keep a eye on this

#22

*** Sierra RS Custard ***

iTrader: (3)

superb project, I really like the 1UZFE lumps, its amazing what they are capable of for so little money spent, you are right about the stronger internals too, the early ones have monster rods in them as standard.

Thats your one on the left commpared to the later ones that come from higher power cars, they were MASSIVELY over engineered on the early ones

Forged pistons and steel crank too!

Thats your one on the left commpared to the later ones that come from higher power cars, they were MASSIVELY over engineered on the early ones

Forged pistons and steel crank too!

#25

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Cheers for the comments all, my ego loves a good massage

Chip, cheers for the pic of the difference in the rod section, I was going to crack the engine and take a look as I was curious, but was hesitant as it runs lovely and I dont want to cock it up lol.

Jay, not looked at the FIA requirements for a cage, but ran a few iterations through CAD and FEA progs with a load case representing that which destroyed the audi. There are better ways of constructing the cage, but I had to take in to account getting in and out in a hurry in the event of a fire. Bearing in mind that I am a little portly

and dont want to be burnt to death in an accident, this was the most sensible compramise.

and dont want to be burnt to death in an accident, this was the most sensible compramise.

Regards my trade whats one of those?? lol

whats one of those?? lol

PS,

Picked up the prop today, quite a chunky affair, given that its 1440mm in overall length and will have to live with shaft speeds potentially over 9k RPM.....

Pictured next to a coke can and 300mm steel rule for size comparison.

Not had chance to stick it on the scales yet, but I would say its roughly 6kg, which is a big saving over the standard supra prop, which weighed in at 16kg! Albeit with a bearing in the centre....

Chip, cheers for the pic of the difference in the rod section, I was going to crack the engine and take a look as I was curious, but was hesitant as it runs lovely and I dont want to cock it up lol.

Jay, not looked at the FIA requirements for a cage, but ran a few iterations through CAD and FEA progs with a load case representing that which destroyed the audi. There are better ways of constructing the cage, but I had to take in to account getting in and out in a hurry in the event of a fire. Bearing in mind that I am a little portly

and dont want to be burnt to death in an accident, this was the most sensible compramise.

and dont want to be burnt to death in an accident, this was the most sensible compramise.Regards my trade

PS,

Picked up the prop today, quite a chunky affair, given that its 1440mm in overall length and will have to live with shaft speeds potentially over 9k RPM.....

Pictured next to a coke can and 300mm steel rule for size comparison.

Not had chance to stick it on the scales yet, but I would say its roughly 6kg, which is a big saving over the standard supra prop, which weighed in at 16kg! Albeit with a bearing in the centre....

#27

Lucifer II - 666

Don't beg pal, it's demeaning

Humour out the way, do those side bars make that much of a difference?

Does having the cross bar benieth the roof pannel not matter?

Just I have seen many fit those side bars now and tbh thought it was a fasion statement following new WRC cars etc

As I have the internal cross bar benieth the roof pannel but no side bars like were discussing and don't want to be paranoid now thinking a role could bring the front section of roof in on itself like the Audi.

Kev.

#28

Lost for life.....

Join Date: Jan 2008

Location: under my car

Posts: 441

Likes: 0

Received 0 Likes

on

0 Posts

Cheers for the comments folks.

Regards the question of engine choice: Firstly, relative to my income, an M3 or M5 V8 is not cheap. The 1UZFE was ~ £250. Thats cheap.

Personally, I think that a large part of the fun is in the making. Overcoming problems and re-engineering certain aspects of the overall package float my boat much more than a plug and play solution.

Secondly, with the addition of a suitable turbo, I dont think 400-450 would be too much of a problem, so plenty of scope for improvement there. Which is the main reason that everything is so strong. The gearbox will take 500 ponies no bother, as will the rest of the drive train.

Regards the question of engine choice: Firstly, relative to my income, an M3 or M5 V8 is not cheap. The 1UZFE was ~ £250. Thats cheap.

Personally, I think that a large part of the fun is in the making. Overcoming problems and re-engineering certain aspects of the overall package float my boat much more than a plug and play solution.

Secondly, with the addition of a suitable turbo, I dont think 400-450 would be too much of a problem, so plenty of scope for improvement there. Which is the main reason that everything is so strong. The gearbox will take 500 ponies no bother, as will the rest of the drive train.

But 3.8 is a 24-valve straight-6 and not that expensive.

That can be big fun for sure, mate.

Not massive power, but it will do the trick just nicely....

Keep up the good work, buddy ...

#29

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Kev,

The problem arises when the fwd leg of the cage has 2 bends in it. This basically turns it in to a spring, and any load in the direction of the one that caused such damage to that audi, would put the members in to bending.

The roof bars, if hit in the same direction, would not provide that much more protection, as they too would be in bending. The bars that I have put in, or bars that come from the roll hoop and intersect in the same sort of place, provide a member that is in compression in a roof impact, hopefully saving my life or something....

or something....

Edit, like this Aston!

The problem arises when the fwd leg of the cage has 2 bends in it. This basically turns it in to a spring, and any load in the direction of the one that caused such damage to that audi, would put the members in to bending.

The roof bars, if hit in the same direction, would not provide that much more protection, as they too would be in bending. The bars that I have put in, or bars that come from the roll hoop and intersect in the same sort of place, provide a member that is in compression in a roof impact, hopefully saving my life

or something....

or something....Edit, like this Aston!

Last edited by Mr Whippy; 23-11-2011 at 05:49 PM.

#30

Don't beg pal, it's demeaning

Humour out the way, do those side bars make that much of a difference?

Does having the cross bar benieth the roof pannel not matter?

Just I have seen many fit those side bars now and tbh thought it was a fasion statement following new WRC cars etc

As I have the internal cross bar benieth the roof pannel but no side bars like were discussing and don't want to be paranoid now thinking a role could bring the front section of roof in on itself like the Audi.

Kev.

Humour out the way, do those side bars make that much of a difference?

Does having the cross bar benieth the roof pannel not matter?

Just I have seen many fit those side bars now and tbh thought it was a fasion statement following new WRC cars etc

As I have the internal cross bar benieth the roof pannel but no side bars like were discussing and don't want to be paranoid now thinking a role could bring the front section of roof in on itself like the Audi.

Kev.

#31

If i can give you a bit of advice mate take the center hoop cross bar out

http://img.photobucket.com/albums/v6...k/IMAG0116.jpg

then v it to the top of the tunnel it will take out more twist in the rear floor for the power you are going to run

like this

http://img.photobucket.com/albums/v6...k/IMAG0116.jpg

then v it to the top of the tunnel it will take out more twist in the rear floor for the power you are going to run

like this

#32

Lucifer II - 666

Thanks lads, I want side bars now

#36

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Jay, a good call, I shall have a look see.

Beefy, the supra diff came on a supra I bought for the R154 gearbox, which funnily enough, I still have the engine etc. For sale as it happens

Regards weight, its somewhere between 36 and 38kg if I remember correctly. Big, and properly strong though!

Beefy, the supra diff came on a supra I bought for the R154 gearbox, which funnily enough, I still have the engine etc. For sale as it happens

Regards weight, its somewhere between 36 and 38kg if I remember correctly. Big, and properly strong though!

#38

I've found that life I needed.. It's HERE!!

cracking project and imo the perfect engine choice as well

good call on the supra diff as you would have had to strengthen the mountings on the E30 setup anyway so may as well put a bullet proof diff in there plus you already had it anyway

good call on the supra diff as you would have had to strengthen the mountings on the E30 setup anyway so may as well put a bullet proof diff in there plus you already had it anyway

#39

Oderint dum metuant

Thread Starter

Join Date: Mar 2005

Location: You cant have pie without coolWhip

Posts: 693

Likes: 0

Received 0 Likes

on

0 Posts

Right, another day on the car today.

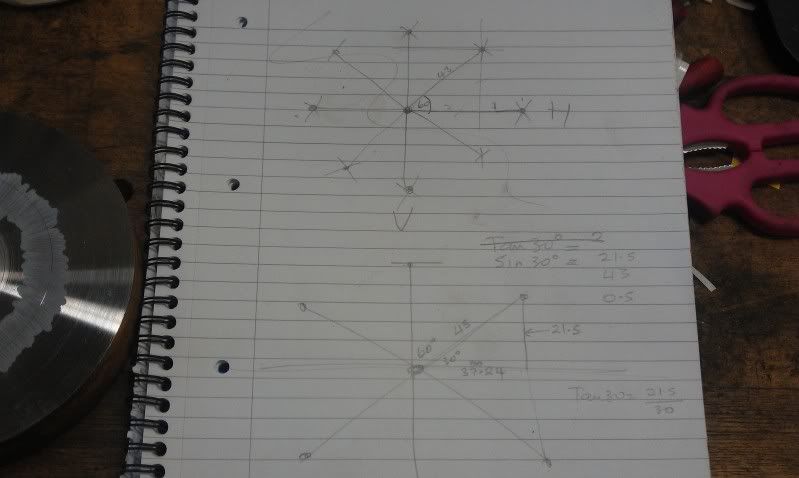

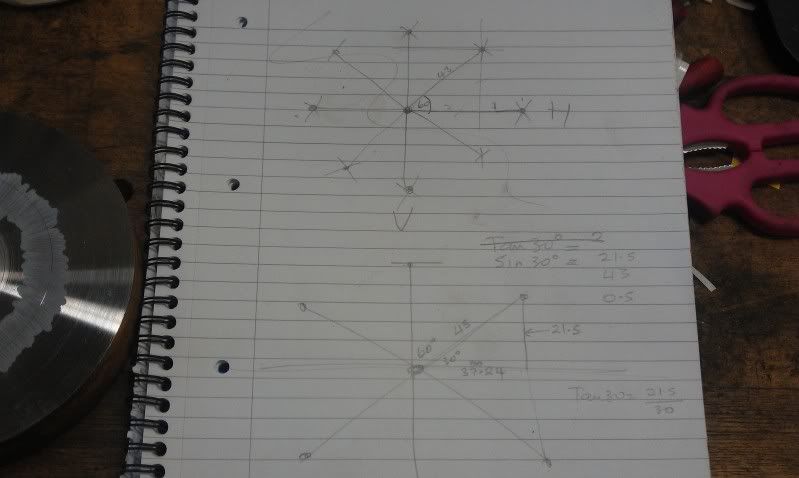

The focus was on getting the wheels turning, so with that in mind some GCSE maths was in order lol

Which allowed us to mark this billet.........

with the co-ordinates for all of the holes required to make a drive shaft adaptor. Obviously Toyota Supra to BMW E30.

It would have been much easier with a rotary table, much faster too!

Then it was on to the lathe for some turning to make the profiles.

A before and after shot.......

Then it was time to offer the spacer and shaft up to the diff, to see how much of a cock up we had made lol

But lo and behold, it could have been made for the job!!

By this time it was getting on a bit, but we managed to fit the diff and prop, to find that clearance past the petrol tank for a 3.5" prop shaft, is a little sparse!

Next week it will all have to come back out for some mods so that it all clears. Oh well, not to worry!

The focus was on getting the wheels turning, so with that in mind some GCSE maths was in order lol

Which allowed us to mark this billet.........

with the co-ordinates for all of the holes required to make a drive shaft adaptor. Obviously Toyota Supra to BMW E30.

It would have been much easier with a rotary table, much faster too!

Then it was on to the lathe for some turning to make the profiles.

A before and after shot.......

Then it was time to offer the spacer and shaft up to the diff, to see how much of a cock up we had made lol

But lo and behold, it could have been made for the job!!

By this time it was getting on a bit, but we managed to fit the diff and prop, to find that clearance past the petrol tank for a 3.5" prop shaft, is a little sparse!

Next week it will all have to come back out for some mods so that it all clears. Oh well, not to worry!