astra gte turbo, track car

#201

PassionFord Post Troll

Thread Starter

mine used to dip like that, i then put a thicker front + rear ARB and 300lbs springs,

now it's fine

under 1m20 is my aim, i have no idea if the car + driver is capable..lol

1m22 is a good time, was the track clear for you?

mind if you got all those issues i cant see wht you cant knock off a few seconds

now it's fine

under 1m20 is my aim, i have no idea if the car + driver is capable..lol

1m22 is a good time, was the track clear for you?

mind if you got all those issues i cant see wht you cant knock off a few seconds

i dont know if the track was clear or not as my video was not running for that session

the problem with mine dipping is going into the corner its making the rear very very light it seams once your in the corner it settles in but it really struggles with stability while turning in atm.

1:20 is what id like to do with a little more work

1:18 is my ultimate dream time lol but thats prob far from realistic on road tyres.

#202

*** Sierra RS Custard ***

iTrader: (3)

i think a homemade special doubling up the ARB would be a good way to test the theory and then if it gives the gains I think it will in terms of controlling the body roll and wild rear end, then it would be worth investing in a custom bladed one later on which he can fine tune.

Rob will readily admit at this stage though that there is much work required on the driver at combe as the car, as he has never been there other than on an action day and hence has never really had a chance to work on his lines as nearly every corner he comes into his line is compromised by another car.

Im sure it will do under 1:20 next year if he can get out there on a couple of proper trackdays and just make a few minor changes to the setup.

The straightline pace it has is just such a massive asset in terms of beating down laptimes on a circuit with a long straight, he can take several seconds out of my clio for example on just the straight alone!

#203

Professional Waffler

iTrader: (1)

Join Date: May 2003

Location: Cardiff

Posts: 26,931

Likes: 0

Received 0 Likes

on

0 Posts

yeah, thr 205 has the 309 as big brother which came standard with a thock ARB but a direct fit, my rear is a thicker ARB made from scratch to fit (£130) the 205 boys had loads made up

i cant comment on his driving, as i never been on with him, (in car or behind)

but am open to show some lines i have learnt from other drivers and personal exp , even if it just means coming in my car

, even if it just means coming in my car

i will be doing a Combe track day some time, (an open pit day) so plenty of laps to learn from

his straight line speed, scares me ALOT, as i just cant compare at all

unless i buy this if it was a bit cheaper i would have bought it and sold my engine and TB's, i would have 250'ish reliabe no lag power then

if it was a bit cheaper i would have bought it and sold my engine and TB's, i would have 250'ish reliabe no lag power then  which would make my car a little nippy then

which would make my car a little nippy then

http://www.306gti6.com/forum/showthr...=121145&page=1

here are few pics of mine at combe you can see the difference

you can see the difference

i cant comment on his driving, as i never been on with him, (in car or behind)

but am open to show some lines i have learnt from other drivers and personal exp

i will be doing a Combe track day some time, (an open pit day) so plenty of laps to learn from

his straight line speed, scares me ALOT, as i just cant compare at all

unless i buy this

http://www.306gti6.com/forum/showthr...=121145&page=1

here are few pics of mine at combe

#209

*** Sierra RS Custard ***

iTrader: (3)

Without a doubt currently, and possibly than he can ever achieve even with changes he is likely to make, the astra doesnt lend itself as well to corners as our french shit does out of the box so he has to work harder at modifying it to get to the same point.

#211

Professional Waffler

iTrader: (1)

Join Date: May 2003

Location: Cardiff

Posts: 26,931

Likes: 0

Received 0 Likes

on

0 Posts

i've yet to have mine setup right too, it has new adj TCA's on there ( me and paul made them) so many changes to happen to get more castor and camber, but as you say the french crap does have a leading edge in handling, and a little lighter too

#213

PassionFord Post Troll

Thread Starter

Yeh tis a shame te gte is so poor out the box, there are plenty of other things icould change to but ATM I'll stick with the challenge lol

for instance spiky essentric top mounts are the only front suspension adjustment availble as standard and with those fitted and in the most caster giving possition I have half a deg of possitive caster on the drivers side !

New lower arms don't help much as if you go forward the drive shaft hits the oil filter l, so I'm going to have to cut the strut tops out move them back then move the ball joint forward to get it where I want it, not a days work

My biggest problem with driver skill is I don't have a chance to try and gain any ATM I'm always just tryin to keep the car onthe road as it is a little bit of a handfull ATM I'm hoping the changes I make before rs combe allow me to stop worrying about if the backend wants to come out at 120 mph around folly and stRt looking into how I'm taking folly lol

for instance spiky essentric top mounts are the only front suspension adjustment availble as standard and with those fitted and in the most caster giving possition I have half a deg of possitive caster on the drivers side !

New lower arms don't help much as if you go forward the drive shaft hits the oil filter l, so I'm going to have to cut the strut tops out move them back then move the ball joint forward to get it where I want it, not a days work

My biggest problem with driver skill is I don't have a chance to try and gain any ATM I'm always just tryin to keep the car onthe road as it is a little bit of a handfull ATM I'm hoping the changes I make before rs combe allow me to stop worrying about if the backend wants to come out at 120 mph around folly and stRt looking into how I'm taking folly lol

#214

Professional Waffler

iTrader: (1)

Join Date: May 2003

Location: Cardiff

Posts: 26,931

Likes: 0

Received 0 Likes

on

0 Posts

yeah, it's never be known for great handling out the box.

ouch on cutting strut tops

i have two mates who live next to combe, one race's there and there have done hundreds and hundreds of laps there, so i have taken advice from them, and been out with them, they can properly pedal around there, maybe i can get you out with them

light back end at 120, does not sound like fun

ouch on cutting strut tops

i have two mates who live next to combe, one race's there and there have done hundreds and hundreds of laps there, so i have taken advice from them, and been out with them, they can properly pedal around there, maybe i can get you out with them

light back end at 120, does not sound like fun

#215

PassionFord Post Troll

Thread Starter

time for a bit of a update (from 2 weeks ago)

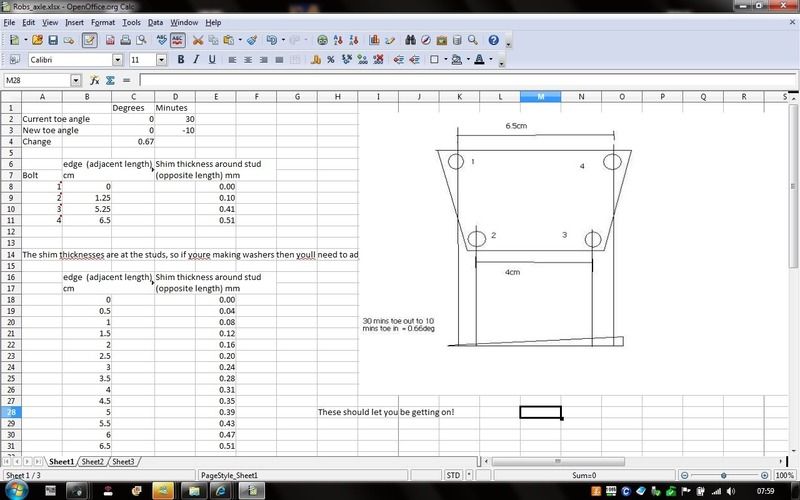

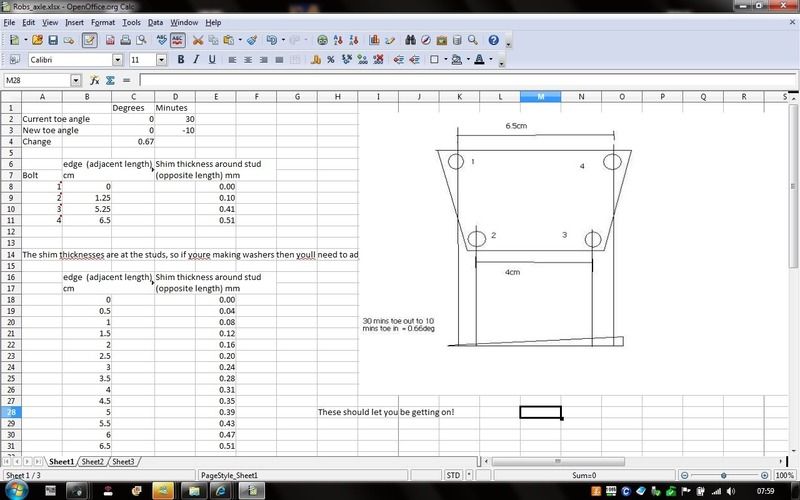

first off been doing a little maths have worked out that with the length of my front shocks to gain 1 deg of caster or camber i need to move the top or bottom of the shock by roughtly 11mm, also with the help of alister olsen the amount of caster i will gain just by dropping the rear is around 1.5 degs !! at the moment i have just under a deg on the passnegers side and 1.5 degs on the drivers and i would like to achive 4 degs.

so the plan is atm to lower the rear to gain the 1.5 avalible then modify the lower arms to push the ball joint forward which should allow me to have the 4 degs i want atm

this very very poor paintshop should give you an idea of my plans

first stage was to get hold of some lower arm parts for the moding, quick post on ASTRA-MK2 came up trumps and today i recived

i shall get some pics up once i start to mod them.

and now onto the larger work ever since i built the engine its smoked on tick over when cold and burnt a little oil in use this has always been put down to the total seal piston rings that seam to be very fussy on running in and bore honing.

anyway i decided i wanted to sort it out and in true fashion it spiralled lol

ive got most of the parts now for the rebuild

new block bored to 87mm fitted with oil jets

omega pistons and arrow sbd rods also have a girdle for the new engine, a opc vauxhall steel crank and zlet pump and pickup pipe.

decided to order a set of solid lifter profile cams from steveboyslim to quiten it down as the solids obviously dont like being on hydraulic cams.

and finally just cause im feeling a little picture whore today, a picture of my new side extension on my tool box

[IMG]http://img.photobucket.com/albums/v192/twitchell/d786b08d.jpg[/IMG

first off been doing a little maths have worked out that with the length of my front shocks to gain 1 deg of caster or camber i need to move the top or bottom of the shock by roughtly 11mm, also with the help of alister olsen the amount of caster i will gain just by dropping the rear is around 1.5 degs !! at the moment i have just under a deg on the passnegers side and 1.5 degs on the drivers and i would like to achive 4 degs.

so the plan is atm to lower the rear to gain the 1.5 avalible then modify the lower arms to push the ball joint forward which should allow me to have the 4 degs i want atm

this very very poor paintshop should give you an idea of my plans

first stage was to get hold of some lower arm parts for the moding, quick post on ASTRA-MK2 came up trumps and today i recived

i shall get some pics up once i start to mod them.

and now onto the larger work ever since i built the engine its smoked on tick over when cold and burnt a little oil in use this has always been put down to the total seal piston rings that seam to be very fussy on running in and bore honing.

anyway i decided i wanted to sort it out and in true fashion it spiralled lol

ive got most of the parts now for the rebuild

new block bored to 87mm fitted with oil jets

omega pistons and arrow sbd rods also have a girdle for the new engine, a opc vauxhall steel crank and zlet pump and pickup pipe.

decided to order a set of solid lifter profile cams from steveboyslim to quiten it down as the solids obviously dont like being on hydraulic cams.

and finally just cause im feeling a little picture whore today, a picture of my new side extension on my tool box

[IMG]http://img.photobucket.com/albums/v192/twitchell/d786b08d.jpg[/IMG

#216

PassionFord Post Troll

Thread Starter

(last week)

went out to the garage last night a checked the bores to ensure they had been bored to the correct clearence, then gapped the rings correctly, should be able to go out again tonight and start to put the jigsaw puzzle together.

big thanks to al olsen here i was chatting to him about shimming the rear beam as mine is not straight and at the moment toes out so could explain some of my handling issues, but because the rear hub does not have square bolt fixings if you just shim the rear to increase toe in then it causes the wheel to ''twist'' and can remove camber when you add the toe in which is not ideal

so i measure the hole distances and sent them over to al who then worked out the exact amount i need to shim each bolt to keep the camber the same as it is and just adjust the caster

not only did he work out how much ill have to move in a theretical world he also worked out the effect that using a washer would have on the possition.

these settings should allow my beat to toe in on the drivers side by 10 seconds instead of toeing out by 30 !!

well thats the head off and boxed ready to send to steveboyslim ready for the new camshafts

had a look into the turbo tonight once i got it off and there is no wet oil anymore so im hoping the new oil drain has solved that problem.

had a few deliverys today aswell new set of R888's as mine are starting to look like they have seen better days

and because im changing the crank to an xer one i now need to use a late cambelt set-up so got a new set of verniers, i also bought some steel cambelt rollers as the standard plastic ones have been know to fail.

went out to the garage last night a checked the bores to ensure they had been bored to the correct clearence, then gapped the rings correctly, should be able to go out again tonight and start to put the jigsaw puzzle together.

big thanks to al olsen here i was chatting to him about shimming the rear beam as mine is not straight and at the moment toes out so could explain some of my handling issues, but because the rear hub does not have square bolt fixings if you just shim the rear to increase toe in then it causes the wheel to ''twist'' and can remove camber when you add the toe in which is not ideal

so i measure the hole distances and sent them over to al who then worked out the exact amount i need to shim each bolt to keep the camber the same as it is and just adjust the caster

not only did he work out how much ill have to move in a theretical world he also worked out the effect that using a washer would have on the possition.

these settings should allow my beat to toe in on the drivers side by 10 seconds instead of toeing out by 30 !!

well thats the head off and boxed ready to send to steveboyslim ready for the new camshafts

had a look into the turbo tonight once i got it off and there is no wet oil anymore so im hoping the new oil drain has solved that problem.

had a few deliverys today aswell new set of R888's as mine are starting to look like they have seen better days

and because im changing the crank to an xer one i now need to use a late cambelt set-up so got a new set of verniers, i also bought some steel cambelt rollers as the standard plastic ones have been know to fail.

#217

PassionFord Post Troll

Thread Starter

this weekend

Had a really busy veru productive weekend

big thanks to alister olsen, he was doing some work in plymouth for the weekend and said he might be able to pop over so i emplyed him for every second he had free lol

or focus was to try and sort out some of the geometery settings on my car.

first was to gain more caster on the front, my first sugestion was to cut the arm in half between the ball joint and the arm mount and then reweld it 22mm forward (giving 2 degs of caster), however once we removed the arms it because clear that we could gain the 2 degs by rotating the ball joint in the arm.

as you can see here

we decided this was the new plan due to being able to us an original hole and a drilled hole with just one of the holes needing repairing it would make a very strong arm.

before we started any cutting/welding we put the leg back onto the car and tested that it was giving us the caster we belived it was and to check clearences.

2 degs might not sound like alot but it is surpising the difference it makes

and a check on the oil filter

once we were happy we could start to cut and weld them up, the front bolt hole was now in a possition that could not be drilled so we cout it out and then set about using a repair washer to make a new hole due to the thickness of the metal there would have been a large gap so we built it up with a few half washers first

then a waher ontop to give us a new hole

the rear bolt did not make full contact due to being so close to a ''slope'' so this was also packed with a half washer, welded then ground back to give a flat surface

arms were then welded up ground back and painted black

you can see how much its moved in this picture

thats the front now completed in theory with my shock length 11mm of movement on the lower ball joint is 1 deg and with the lowering of the rear and adjusting the drivers top mount i should now be around 2.5 degs of camber both sides and 4 degs of caster on both sides.

with the front complete it was time to shim the rear beam out came my shiming material, in varring thicknesses

these were then cut into strips

while trying to find the correct sizes i found out i had the .1mm .4mm but no .5 al was toying with the idea of gluing to shims together where as i just started to measure things

and i found a ruler was .5mm perfect so it also got the chop

al then set about cutting a half circle into the shims, the measurements he had worked out were for the shim to be down the center line so the best way to achinve that was to fit the face on the center line

after all the filing and cutting al was starting to feel a little hot so out came the magnums (that came in there own little boxes lol )

and the final job was to fit the axel back up with the shims in place

this should now put my beam toeing in instead of toeing out

once again big thanks to al for the work this weekend

Had a really busy veru productive weekend

big thanks to alister olsen, he was doing some work in plymouth for the weekend and said he might be able to pop over so i emplyed him for every second he had free lol

or focus was to try and sort out some of the geometery settings on my car.

first was to gain more caster on the front, my first sugestion was to cut the arm in half between the ball joint and the arm mount and then reweld it 22mm forward (giving 2 degs of caster), however once we removed the arms it because clear that we could gain the 2 degs by rotating the ball joint in the arm.

as you can see here

we decided this was the new plan due to being able to us an original hole and a drilled hole with just one of the holes needing repairing it would make a very strong arm.

before we started any cutting/welding we put the leg back onto the car and tested that it was giving us the caster we belived it was and to check clearences.

2 degs might not sound like alot but it is surpising the difference it makes

and a check on the oil filter

once we were happy we could start to cut and weld them up, the front bolt hole was now in a possition that could not be drilled so we cout it out and then set about using a repair washer to make a new hole due to the thickness of the metal there would have been a large gap so we built it up with a few half washers first

then a waher ontop to give us a new hole

the rear bolt did not make full contact due to being so close to a ''slope'' so this was also packed with a half washer, welded then ground back to give a flat surface

arms were then welded up ground back and painted black

you can see how much its moved in this picture

thats the front now completed in theory with my shock length 11mm of movement on the lower ball joint is 1 deg and with the lowering of the rear and adjusting the drivers top mount i should now be around 2.5 degs of camber both sides and 4 degs of caster on both sides.

with the front complete it was time to shim the rear beam out came my shiming material, in varring thicknesses

these were then cut into strips

while trying to find the correct sizes i found out i had the .1mm .4mm but no .5 al was toying with the idea of gluing to shims together where as i just started to measure things

and i found a ruler was .5mm perfect so it also got the chop

al then set about cutting a half circle into the shims, the measurements he had worked out were for the shim to be down the center line so the best way to achinve that was to fit the face on the center line

after all the filing and cutting al was starting to feel a little hot so out came the magnums (that came in there own little boxes lol )

and the final job was to fit the axel back up with the shims in place

this should now put my beam toeing in instead of toeing out

once again big thanks to al for the work this weekend

#219

PassionFord Post Troll

Thread Starter

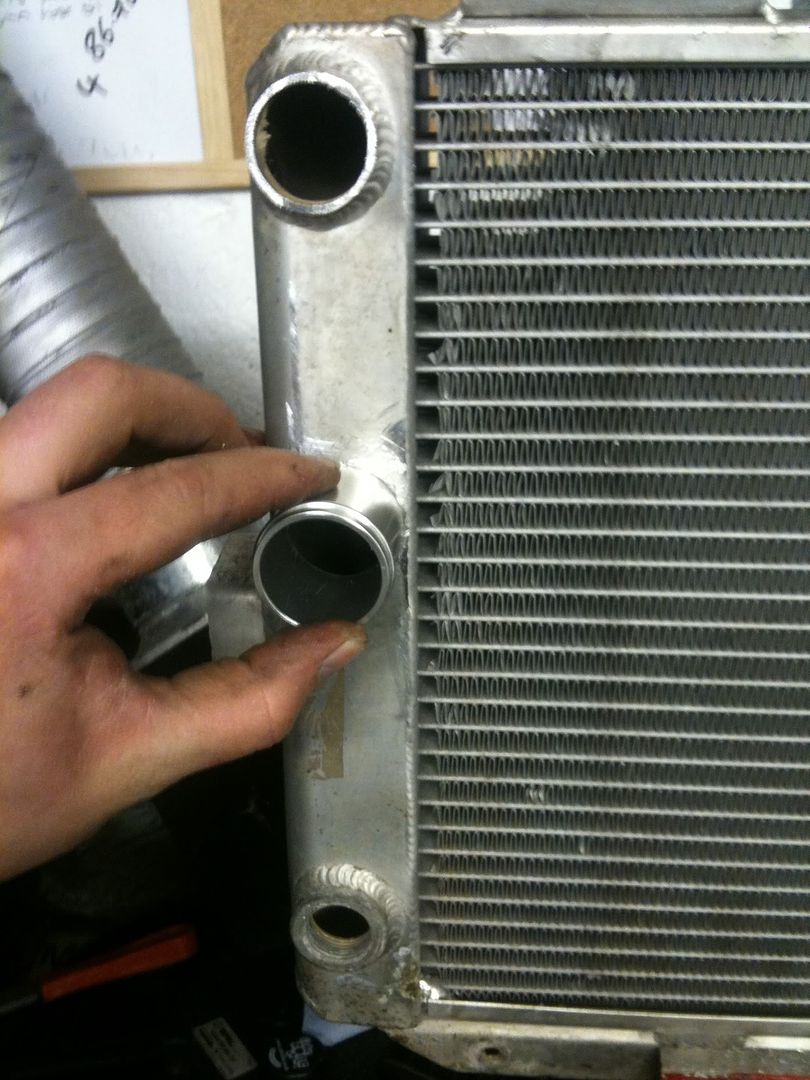

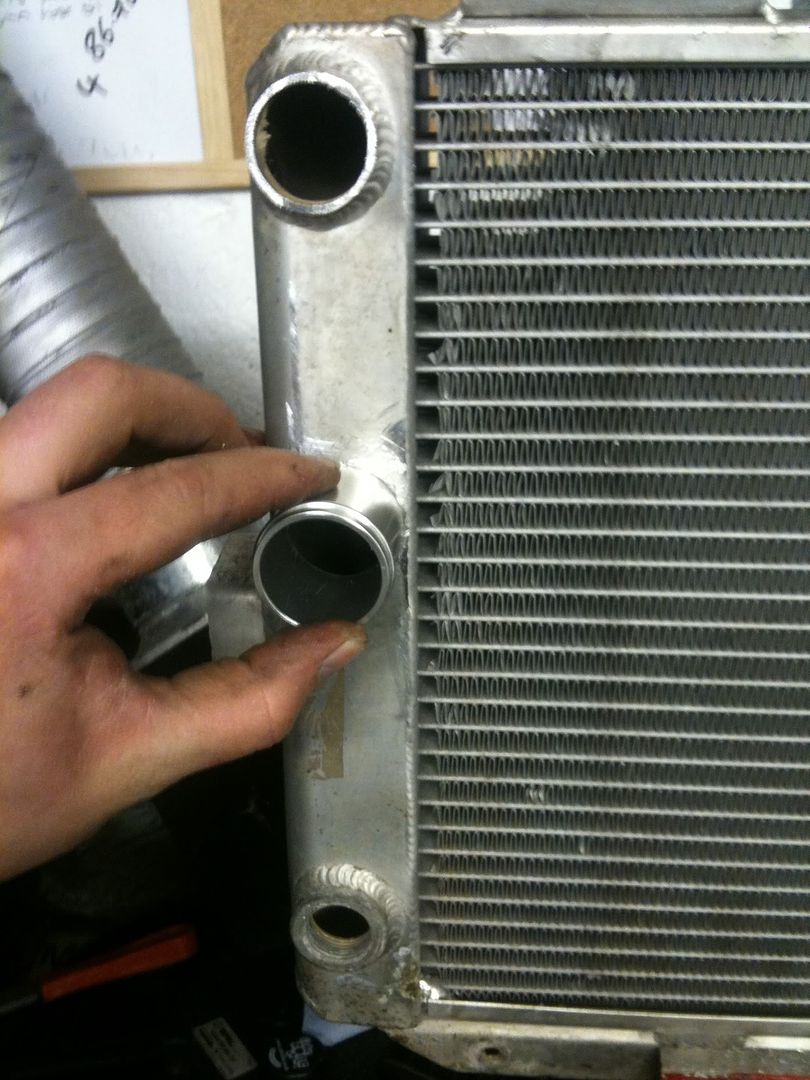

After my last trip to combe it became aparent that my radiator was a little underspec'd untill now i had been using a corsa c rad and it had been coping well with power levels upto 330 bhp but it did not enjoy a 20 deg day with 2 bar of boost lol.

i was having a look though passionford when i see someone selling a pro alloy one for £40 because it had been damaged but had already been repaired so after i snapped there arm off i had in my possession one pro alloy cossie rad, as you can see there is a ''small'' size difference lol

putting it into the hole and i could not have asked for a better size if i spec'd it myself perfect use of all avalible space

the only real problem with it is the inlet and outlet are on different sides of the rad,my first intension was just to cut them off and move them around and have them rewelded however the cossie uses 32mm pipes but the vauxhall hoses need 35.

so i ordered a hose joiner that is 35mm at both ends, i ordered one with a flange in the middle as this might have been easier to fit

but once i have cut it in half i found it did not work that well so cut the flanges off, i then redrilled the holes with one in the possition for a top hose and one half way down like on a vauxhall

i have made blanking plates for the holes i created and im having a boss welded into the top ''cossie'' one for the water feed for the turbo, its going off for welding tonight.

hopefully this should cure my coolent issues

i was having a look though passionford when i see someone selling a pro alloy one for £40 because it had been damaged but had already been repaired so after i snapped there arm off i had in my possession one pro alloy cossie rad, as you can see there is a ''small'' size difference lol

putting it into the hole and i could not have asked for a better size if i spec'd it myself perfect use of all avalible space

the only real problem with it is the inlet and outlet are on different sides of the rad,my first intension was just to cut them off and move them around and have them rewelded however the cossie uses 32mm pipes but the vauxhall hoses need 35.

so i ordered a hose joiner that is 35mm at both ends, i ordered one with a flange in the middle as this might have been easier to fit

but once i have cut it in half i found it did not work that well so cut the flanges off, i then redrilled the holes with one in the possition for a top hose and one half way down like on a vauxhall

i have made blanking plates for the holes i created and im having a boss welded into the top ''cossie'' one for the water feed for the turbo, its going off for welding tonight.

hopefully this should cure my coolent issues

#220

Professional Waffler

iTrader: (1)

Join Date: May 2003

Location: Cardiff

Posts: 26,931

Likes: 0

Received 0 Likes

on

0 Posts

making good progress on the suspension dude, soon have it handling real nice, and can have some confidence in it.

rad looks bloody good fit, i need a small slim fan like that, mines rubbish.

rad looks bloody good fit, i need a small slim fan like that, mines rubbish.

#221

PassionFord Post Troll

Thread Starter

yeh i was very suprised about the rad fitting so well.

well first off i have had a little bit of bad news i was hoping to have my cylinder head back intime to put the new engine into the car before rscombe on the 3rd of july due to a unforscene head issue should have it all back for total vauxhall live thou.

in the meantime chip has ordered some rings for the bottom end im going to re-ring it and put a standard head on, turn the power down to around 330-350 and then do rs combe with that im not bothered atm as im looking forward more to the changes in suspension than the overall pace for my next outing so this should all work out well in the end.

been doing one of them jobs you just keep putting off, i have a fibreglass bonnet and when i first fitted it i tried to fit it on 4 pins however the front ones were not just a straight fit and needed some washers welding on, because te bonnet can use the standard pin this has always been put off lol, but as im starting to do the ''little'' jobs no one ever wants to do.

only problem was as some will notice just as we started to weld we ran out of gas ARRRRGGGGG

ill get some more gas next week and go around the rest of them.

well first off i have had a little bit of bad news i was hoping to have my cylinder head back intime to put the new engine into the car before rscombe on the 3rd of july due to a unforscene head issue should have it all back for total vauxhall live thou.

in the meantime chip has ordered some rings for the bottom end im going to re-ring it and put a standard head on, turn the power down to around 330-350 and then do rs combe with that im not bothered atm as im looking forward more to the changes in suspension than the overall pace for my next outing so this should all work out well in the end.

been doing one of them jobs you just keep putting off, i have a fibreglass bonnet and when i first fitted it i tried to fit it on 4 pins however the front ones were not just a straight fit and needed some washers welding on, because te bonnet can use the standard pin this has always been put off lol, but as im starting to do the ''little'' jobs no one ever wants to do.

only problem was as some will notice just as we started to weld we ran out of gas ARRRRGGGGG

ill get some more gas next week and go around the rest of them.

#223

PassionFord Post Troll

Thread Starter

quick update for tonight decided to have a look into the rear archs, i had to jack the car up to clear the tyres but this was not ideal and was effecting the handling alot, i was going to put it into a body shop but im not going to have time before combe, so i just thought id have a go at it.

first of all got out the heat gun and warmed the arch to try and stop the paint from cracking then gentally beat the lip upwards, i was quite surprised as it was not overly hard lol

and the tyre now clears on the drivers side just need to do the passengers at some point next week

first of all got out the heat gun and warmed the arch to try and stop the paint from cracking then gentally beat the lip upwards, i was quite surprised as it was not overly hard lol

and the tyre now clears on the drivers side just need to do the passengers at some point next week

#227

10K+ Poster!!

I ran the same setup on 16" Mo's and had loads of clearance, Martin Hadland ran the same on the metro which was on 15's but I know he had to modify the kit slightly to get it all to fit.

Good progress Rob, cars coming on leaps and bounds.

#229

PassionFord Post Troll

Thread Starter

time for a gloomy update

simon(STT) came around last night to give me a hand as im on quite a tight schedual to get the car finished for mot before the weekend, as i will not have time after the weekend as im back at work.

the list of jobs was not that long re-ring the block and then just fit a new head on, this is a standard head untill i can fit my new engine between rs combe and tvl then i would have tonight for any finishing jobs/mot bits then for mot on thursday.

once simon was down we pulled out the pistons and gave the bores a quick hone with a bore deglazer to help the rings bed in, while simon was cleaning and checking the ring groves on the pistons i pulled out a ring to see if they needed gapping

and there was a big problem staring us in the face

ummmm thats a little large lol

so i decided to give it a measure

2.04mm now to those that dont built engines that figure wont mean much so ill tell you what it should be, it should be somewhere in the region of 0.3-0.4mm.

it was quite obvious straight away what had happened and a quick look at the box confimed it i had been send 86mm not 86.5mm rings, have spoken to steve who could not apoligise enough and is sending a set of 86.5mm rings out today special delivery so ill have them tommorow morning (fingers crossed)

this will give me just tommorow to get the car built and ready for an mot on friday so fingers crossed it passes first time.

i had a second bad bit of news last night aswell the cheap pro alloy radiator i bought is going to make a wonderfull door stop, the repair that had been carried out on leaked, but not only did that row leak when we reapaired that one we found another 7!!!! that leaked meaning far to much of the rad is going to be sealed up to stop it leaking and if that many leak already it aint going to be long till more do, so its back to the drawing board on the rad front.

this problem spured me on to make another change to the car ive been thinking about for a while make the slam pannel removable, to change the rad in my car i have to remove the turbo, manifold and external wastegate, this as you can imagine is a pain in the arse, and with the current rad problem i have no choice but to fit the corsa rad to get me to mot and look for something else to fit next week.

so out came the tape, a hacksaw and a simon few cuts later and we were left with

this should make removing the rad alot easier, i dont think im going to use the standard metal back in the whole as it weighs alot for something that now does nothing so im prob going to make a simple alloy one for the time being with maybe a carbon one at a later date

going out tonight to put the front supension back together and make sure the car is in a possition that its just a head gasket rebuilt tommorow night, simon is hoping to come down again tommorow to help and is going to see if one of his mates is free aswell so it will be all hands on deck lol.

simon(STT) came around last night to give me a hand as im on quite a tight schedual to get the car finished for mot before the weekend, as i will not have time after the weekend as im back at work.

the list of jobs was not that long re-ring the block and then just fit a new head on, this is a standard head untill i can fit my new engine between rs combe and tvl then i would have tonight for any finishing jobs/mot bits then for mot on thursday.

once simon was down we pulled out the pistons and gave the bores a quick hone with a bore deglazer to help the rings bed in, while simon was cleaning and checking the ring groves on the pistons i pulled out a ring to see if they needed gapping

and there was a big problem staring us in the face

ummmm thats a little large lol

so i decided to give it a measure

2.04mm now to those that dont built engines that figure wont mean much so ill tell you what it should be, it should be somewhere in the region of 0.3-0.4mm.

it was quite obvious straight away what had happened and a quick look at the box confimed it i had been send 86mm not 86.5mm rings, have spoken to steve who could not apoligise enough and is sending a set of 86.5mm rings out today special delivery so ill have them tommorow morning (fingers crossed)

this will give me just tommorow to get the car built and ready for an mot on friday so fingers crossed it passes first time.

i had a second bad bit of news last night aswell the cheap pro alloy radiator i bought is going to make a wonderfull door stop, the repair that had been carried out on leaked, but not only did that row leak when we reapaired that one we found another 7!!!! that leaked meaning far to much of the rad is going to be sealed up to stop it leaking and if that many leak already it aint going to be long till more do, so its back to the drawing board on the rad front.

this problem spured me on to make another change to the car ive been thinking about for a while make the slam pannel removable, to change the rad in my car i have to remove the turbo, manifold and external wastegate, this as you can imagine is a pain in the arse, and with the current rad problem i have no choice but to fit the corsa rad to get me to mot and look for something else to fit next week.

so out came the tape, a hacksaw and a simon few cuts later and we were left with

this should make removing the rad alot easier, i dont think im going to use the standard metal back in the whole as it weighs alot for something that now does nothing so im prob going to make a simple alloy one for the time being with maybe a carbon one at a later date

going out tonight to put the front supension back together and make sure the car is in a possition that its just a head gasket rebuilt tommorow night, simon is hoping to come down again tommorow to help and is going to see if one of his mates is free aswell so it will be all hands on deck lol.

#231

PassionFord Post Troll

Thread Starter

sorry for no updates before the trackday but it all got a little busy with me running out of time.

i managed however to get it all in one piece for rs combe, but more about that in a min.

got a few new bits for when it went together this time

one piece rear water hose, i had been using a blocked 3 way one but this is much better

i got a new camera for the car now its a contor hd camera and will record in 1080P im recording in much lower deff atm as my computer will not actually edit the hd movies

made a quick bracket to hold onto the cage as you now have to have your camera solid mounted at combe sucktion mounts are not legal

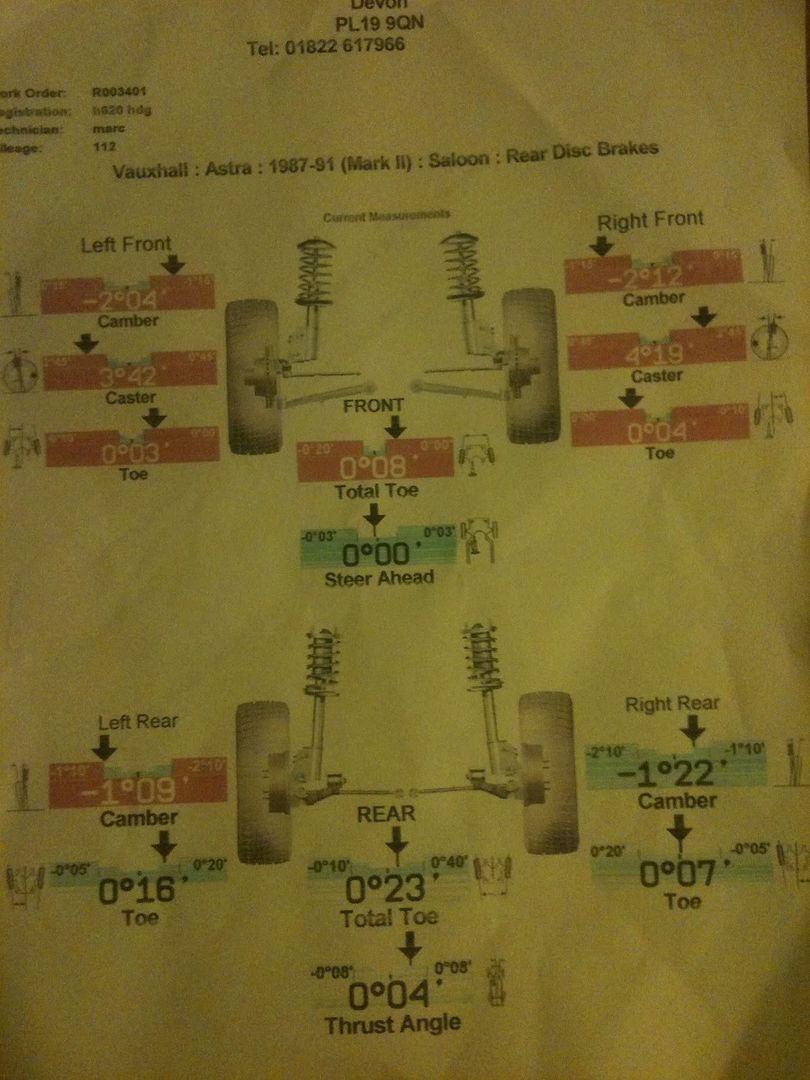

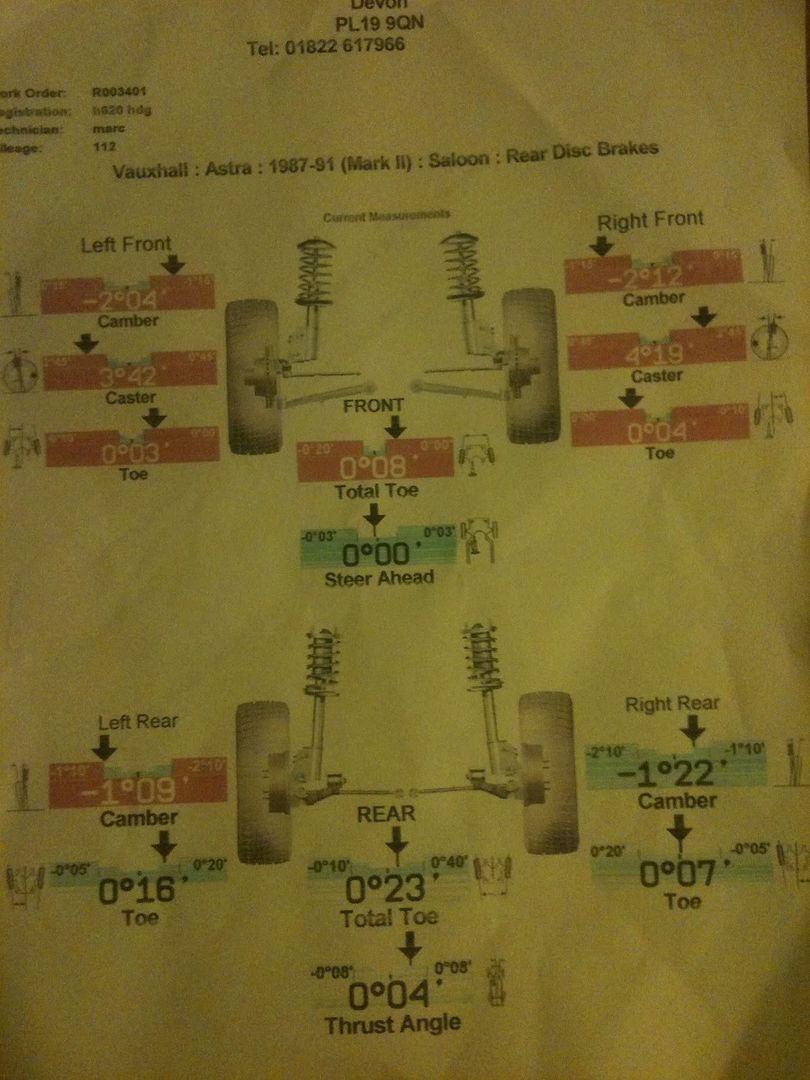

now something important, once it was all running i took it back for some alignment figures

all i now need to do is space the passengers side lower arm forward to match up the caster then re-adjust camber and tracking and it should be at the figures i want, the rear now toes in the correct amount alister worked out.

to say im happy is a understatment from the second i had the alignment done it was clear that the car had now stepped up to a different league of handling

it was just so much more positive, had good mechanical grip and the rear now actually follows the front.

the changes that have been made are even noticable from outside the car, the amount of body roll has been drastically reduced.

picture of me using all the kerbs (and a little more lol)

once again i had overheating problems i was not able to use the alloy rad i had bought as when it was pressure tested after welding the new inlets and outlets it was found to be leaking on 7 rows !!

i was able to get a larger rad into the whole for combe thou i fitted a cav turbo diesel rad now obviously not as good as a aftermarket perfermance rad but should have been upto the job but i was only able to complete 2 laps before temp were 110 degs + so i have a quite serious issue.

im not 100% sure what the problem is yet but im about to have a copper core rad custom made and i will fully shield the turbo from the rad as i think there is a possiblity that the heat from the turbo is boiling the water in the rad because of this problem i was only able to complete 2 laps, but they were 2 quite good laps.

my target for the gte has always been to run 1:19 around combe, and i was able to run 1:20 on my second lap with the car handling

so im pretty sure my target will be achived infact im thinking of giving myself a new goal of 1:18

http://www.youtube.com/watch?v=tm9fqJ0cVlU

hope you enjoy

i managed however to get it all in one piece for rs combe, but more about that in a min.

got a few new bits for when it went together this time

one piece rear water hose, i had been using a blocked 3 way one but this is much better

i got a new camera for the car now its a contor hd camera and will record in 1080P im recording in much lower deff atm as my computer will not actually edit the hd movies

made a quick bracket to hold onto the cage as you now have to have your camera solid mounted at combe sucktion mounts are not legal

now something important, once it was all running i took it back for some alignment figures

all i now need to do is space the passengers side lower arm forward to match up the caster then re-adjust camber and tracking and it should be at the figures i want, the rear now toes in the correct amount alister worked out.

to say im happy is a understatment from the second i had the alignment done it was clear that the car had now stepped up to a different league of handling

it was just so much more positive, had good mechanical grip and the rear now actually follows the front.

the changes that have been made are even noticable from outside the car, the amount of body roll has been drastically reduced.

picture of me using all the kerbs (and a little more lol)

once again i had overheating problems i was not able to use the alloy rad i had bought as when it was pressure tested after welding the new inlets and outlets it was found to be leaking on 7 rows !!

i was able to get a larger rad into the whole for combe thou i fitted a cav turbo diesel rad now obviously not as good as a aftermarket perfermance rad but should have been upto the job but i was only able to complete 2 laps before temp were 110 degs + so i have a quite serious issue.

im not 100% sure what the problem is yet but im about to have a copper core rad custom made and i will fully shield the turbo from the rad as i think there is a possiblity that the heat from the turbo is boiling the water in the rad because of this problem i was only able to complete 2 laps, but they were 2 quite good laps.

my target for the gte has always been to run 1:19 around combe, and i was able to run 1:20 on my second lap with the car handling

so im pretty sure my target will be achived infact im thinking of giving myself a new goal of 1:18

http://www.youtube.com/watch?v=tm9fqJ0cVlU

hope you enjoy

Last edited by sbd16v; 11-07-2010 at 08:03 PM.

#233

PassionFord Post Troll

Thread Starter

yeh it feels so much better

i nearly forgot to say that the car had new tyres fitted and because we we rushing the tyre pressures were not checked untill after that session

my 1:20 lap was with

front left 37psi

front right 36psi

rear right 35psi

rear left 90 psi

YES 90 psi !!! the tyre had not had the pressure dropped after having the bead broken.

so there is still a little more to come from tyre pressures

#235

500bhp Cosworth in making

iTrader: (8)

i would try dropping the pressures at front. we race at coombe every year in our saxo vtr with A048 but in throey the same tyre.

we use 23psi in fronts and 40psi in rears as that track you need the rear end loose but you need the low front to pull in. unless the day is really cold then dont raise the fronts slightly. i raced at cadwell the weekend and had 20psi in front and 40psi in rear and it was spot on.

we use 23psi in fronts and 40psi in rears as that track you need the rear end loose but you need the low front to pull in. unless the day is really cold then dont raise the fronts slightly. i raced at cadwell the weekend and had 20psi in front and 40psi in rear and it was spot on.

Thread

Thread Starter

Forum

Replies

Last Post

track.focus'd

Restorations, Rebuilds & Projects.

26

12-08-2015 05:53 PM

Versus_Creations

Pictures, video & Photoshop Forum

24

05-08-2015 09:32 PM